Oct . 21, 2024 23:30 Back to list

How to Replace Seal on Hydraulic Cylinder Wiper for Optimal Performance

Replacing Wiper Seal on Hydraulic Cylinder A Step-by-Step Guide

Hydraulic cylinders are crucial components in various machinery, such as excavators, forklifts, and industrial presses. One of the key elements in maintaining hydraulic cylinder function and longevity is the wiper seal. The wiper seal prevents dirt, dust, and other contaminants from entering the hydraulic cylinder while also protecting the internal seals from wear. Replacing a worn or damaged wiper seal is an essential maintenance task that can enhance the performance and extend the life of your hydraulic system. This article provides a detailed guide on how to replace the wiper seal on a hydraulic cylinder.

Understanding the Components

Before embarking on the replacement process, it’s essential to understand the key components of a hydraulic cylinder, including the wiper seal. The wiper seal sits at the top of the cylinder barrel, ensuring that contaminants do not enter the hydraulic fluid chamber. Signs that the wiper seal may need replacement include visible wear, leaking fluid, or a noticeable deterioration of the seal material.

Tools and Materials Needed

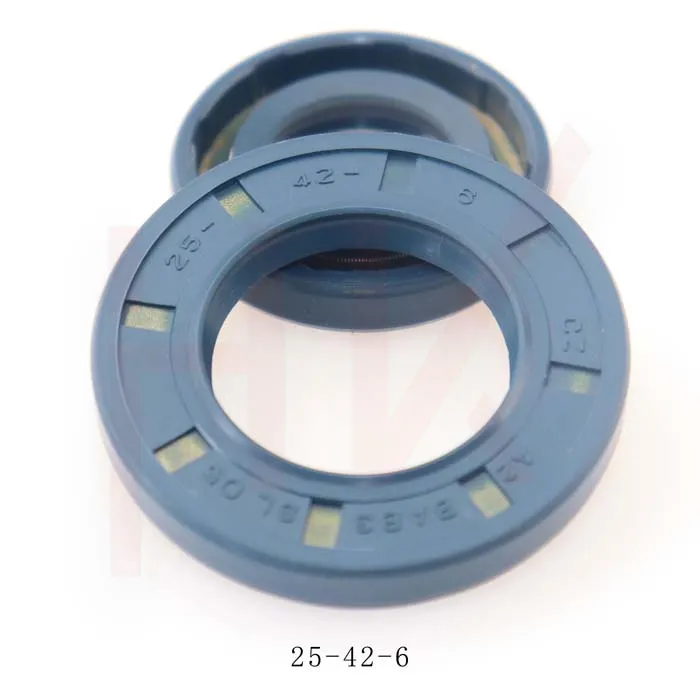

To successfully replace the wiper seal, you will need the following tools and materials 1. New wiper seal (ensure it matches your hydraulic cylinder specifications) 2. Hydraulic fluid 3. Seal removal tool or flat blade screwdriver 4. Clean cloths 5. Measuring caliper 6. Safety goggles and gloves 7. Torque wrench 8. Pliers 9. Lubricant

Step-by-Step Replacement Process

1. Safety First Before starting any work, ensure that the hydraulic system is depressurized. Disconnect the hydraulic lines and make sure to wear safety goggles and gloves to protect yourself from fluid spills and sharp components.

2. Remove the Cylinder from the Equipment If the hydraulic cylinder is attached to machinery, carefully remove it. This may involve unbolting or unscrewing depending on the setup. Use a lifting mechanism if necessary to handle heavy cylinders.

3. Disassemble the Cylinder Take apart the cylinder by removing any end caps or retaining rings securing the cylinder ends. Be cautious during this process, as internal components may have spring tension. Keep track of the order of disassembly for easier reassembly.

replacing wiper seal on hydraulic cylinder

4. Inspect the Components Once disassembled, inspect all components, including the rod, piston, and any internal seals. Look for signs of wear, pitting, or scoring. Address any damaged components to prevent future failures.

5. Remove the Old Wiper Seal With a seal removal tool or flat blade screwdriver, carefully pry out the old wiper seal from its groove. Take care not to damage the cylinder surface as you remove the seal.

6. Clean the Surface Thoroughly clean the groove where the wiper seal sits, ensuring that no debris or old seal material remains. Use a clean cloth and hydraulic fluid for this step. It is crucial as any contaminants can affect the new seal's performance.

7. Install the New Wiper Seal Before installation, lightly lubricate the new wiper seal with hydraulic fluid. This helps with the installation and ensures a good fit. Carefully place the seal into the groove, ensuring it sits evenly without any twists or kinks.

8. Reassemble the Cylinder Once the new wiper seal is in place, reassemble the hydraulic cylinder by reversing the disassembly steps. Make sure to securely fasten all components and properly torque any bolts according to manufacturer's specifications.

9. Reinstall the Cylinder Reattach the hydraulic cylinder to the equipment, ensuring all connections are secure and that you re-establish hydraulic lines properly.

10. Test the System Once everything is reconnected, gradually restore hydraulic pressure and inspect for leaks. Operate the machinery to ensure normal function and that the new wiper seal is working effectively.

Conclusion

Replacing the wiper seal on a hydraulic cylinder is a straightforward process that can significantly improve the performance and efficiency of your hydraulic system. Regular maintenance and timely replacement of worn seals not only prolong the lifespan of the hydraulic cylinder but also enhance operational safety and reliability. By following this guide, you can ensure that your hydraulic systems remain in optimal condition, ready for whatever tasks lie ahead.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories