Nov . 15, 2024 18:50 Back to list

replacing seals in a hydraulic cylinder

Replacing Seals in a Hydraulic Cylinder A Comprehensive Guide

Hydraulic cylinders are crucial components in various machines and equipment, providing the necessary force and motion to perform a wide range of tasks. However, over time, the seals within these cylinders may wear out due to continuous pressure and exposure to hydraulic fluids, leading to leaks and decreased efficiency. Replacing seals in a hydraulic cylinder is an essential maintenance procedure that can restore functionality and extend the life of the cylinder. This article will provide a comprehensive guide on how to replace seals in a hydraulic cylinder effectively.

Understanding Hydraulic Cylinder Seals

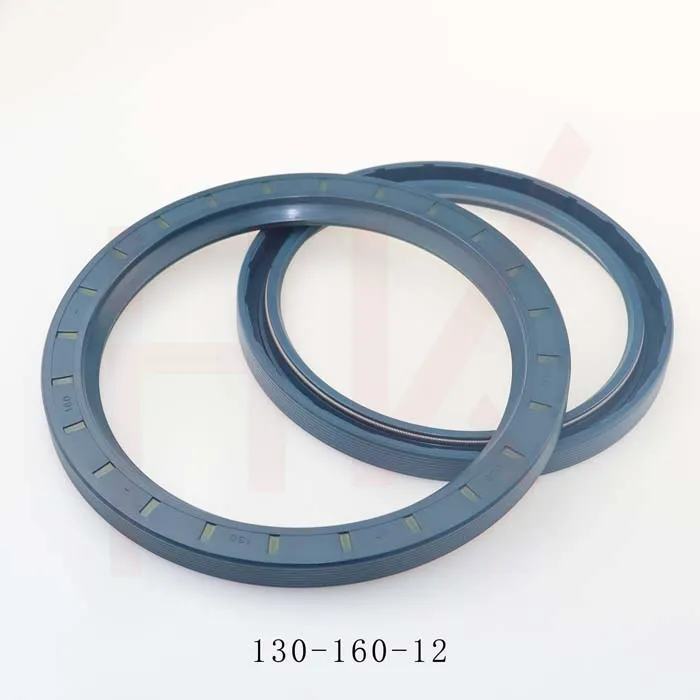

Hydraulic cylinder seals play a pivotal role in maintaining pressure within the cylinder while preventing hydraulic fluid leakage. There are several types of seals used in hydraulic cylinders, including rod seals, piston seals, and wiper seals. Each of these seals serves a specific purpose and is designed to withstand high pressures and various fluid types. Before commencing any maintenance work, it is crucial to identify which seals need to be replaced based on the symptoms observed, such as oil leaks, reduced performance, or cylinder binding.

Tools and Materials Needed

Before starting the replacement process, ensure you have the following tools and materials

- Safety gloves and goggles - Wrenches and screwdrivers - Seal puller - Clean rags or towels - Measuring tools (calipers) - Lubrication oil - Replacement seals (make sure they match your cylinder specifications)

Step-by-Step Replacement Procedure

1. Safety First Before doing any mechanical work, ensure that the hydraulic system is depressurized and the equipment is turned off. Disconnect any power source and allow the cylinder to cool down if it has been in use.

replacing seals in a hydraulic cylinder

2. Disassembly of the Cylinder - Begin by effectively removing the hydraulic cylinder from the equipment. Depending on the cylinder design, you may need to remove mounting brackets or other attachments. - Once free, place the cylinder on a clean, flat surface. - Carefully remove the end caps or covers using the appropriate tools. It’s wise to take pictures during the disassembly process to remember the original arrangement of components.

3. Removing the Old Seals - With the cylinder disassembled, identify the seals that need replacing. Use a seal puller to gently remove the old seals to avoid damaging the cylinder walls. - Clean the grooves and surfaces in which the seals were seated using a clean rag. This step is critical to ensure that debris does not contaminate the new seals.

4. Inspect the Cylinder for Damage - Inspect the cylinder for any signs of wear or damage. Look for scratches or scoring on the rod or cylinder bore, as these may require additional attention.

5. Installing New Seals - Compare the old seals to the new ones to ensure the proper sizes are selected. Installation of seals can be tricky; it’s important to follow the manufacturer's guidelines. - Use a lubrication oil compatible with the hydraulic fluid to lightly coat the seals before installation. This helps them slide into place more easily without damaging the seal material.

6. Reassemble the Cylinder - Carefully reassemble the cylinder, making sure all components are put back in the correct order. Tighten the end caps securely but avoid over-tightening, which can damage seals.

7. Testing - Once the cylinder is reassembled, reconnect it to the hydraulic system and perform a pressure test. Check for leaks and ensure the cylinder operates smoothly.

Conclusion

Replacing seals in a hydraulic cylinder is a straightforward task that can significantly enhance the performance and longevity of the equipment. By following the systematic approach outlined above, you can ensure a successful seal replacement while maintaining safety and efficiency. Regular maintenance checks can prevent unexpected breakdowns and costly repairs, making it an integral part of managing hydraulic systems effectively. Always refer to the manufacturer’s guidelines for specific instructions related to your cylinder model for the best results.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories