Dec . 03, 2024 20:37 Back to list

How to Replace Seals in Hydraulic Cylinders for Optimal Performance and Longevity

Replacing Seals in Hydraulic Cylinders A Comprehensive Guide

Hydraulic cylinders are vital components in various machines and equipment, playing a critical role in converting fluid power into mechanical energy. One of the most common issues that arise with hydraulic cylinders is seal failure. When seals wear out or become damaged, they can lead to fluid leaks, reduced efficiency, and even catastrophic equipment failure. In this article, we will discuss the process of replacing seals in hydraulic cylinders, emphasizing the importance of regular maintenance and the steps involved in the replacement process.

Understanding Hydraulic Cylinder Seals

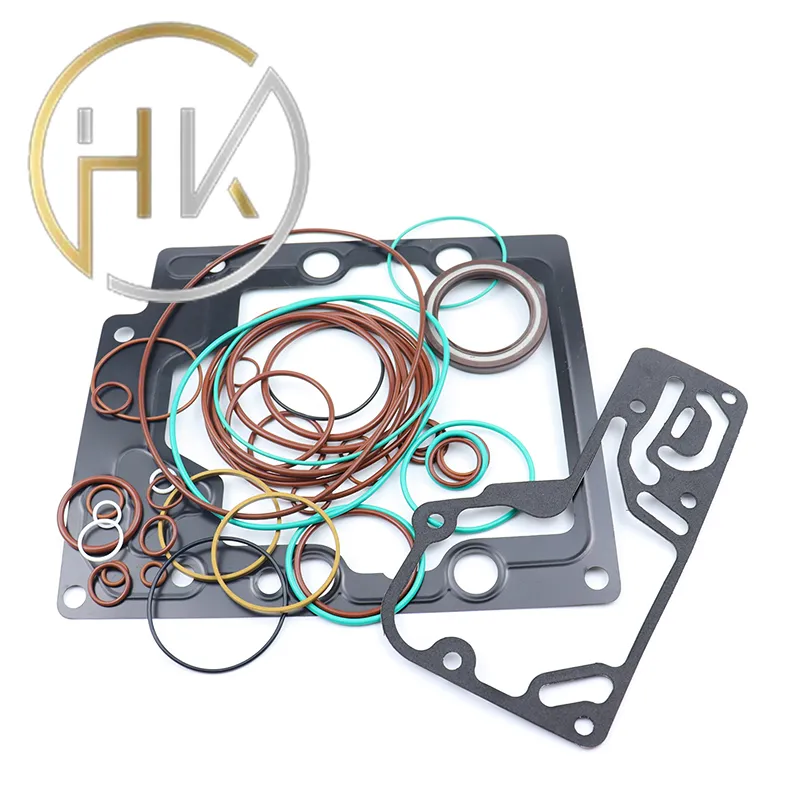

Hydraulic cylinders typically consist of a piston, rod, and seals that help contain the hydraulic fluid within the cylinder. The seals are crucial for maintaining pressure and preventing leaks, which can compromise the cylinder's performance. There are several types of seals used in hydraulic cylinders, including dynamic seals (which operate during movement) and static seals (which remain stationary). Common materials for these seals include rubber, polyurethane, and PTFE, each offering varying degrees of durability and resistance to different fluids.

Signs of Seal Damage

Before diving into the replacement process, it's essential to recognize the signs of seal damage. Common indicators include

1. Fluid Leakage If you notice hydraulic fluid pooling around the cylinder, it's a clear sign that the seals may need replacement. 2. Reduced Performance Difficulty in moving the cylinder or a noticeable drop in speed can indicate wear in the seals. 3. Unusual Noises Banging or grinding sounds during operation may also suggest that seals are failing.

Steps to Replace Seals in Hydraulic Cylinders

Replacing seals in hydraulic cylinders is a task that requires attention to detail, proper tools, and safety precautions. Here’s a step-by-step guide

1. Safety First Before beginning any work, ensure that the hydraulic system is depressurized and locked out. Wear appropriate safety gear, including gloves and goggles.

replacing seals hydraulic cylinder

2. Disassemble the Cylinder Remove the cylinder from the machine. Carefully unscrew or unbolt the components, taking note of the order and orientation for reassembly.

3. Extract the Piston and Rod Once disassembled, gently pull out the piston and rod. Be cautious not to damage any other components during this process.

4. Remove Old Seals Using a seal removal tool, carefully extract the old seals from their grooves. Take care not to scratch or damage the cylinder surfaces.

5. Inspect Components Examine the cylinder, piston, and rod for any signs of wear or damage. Replace any components that may compromise the performance of the hydraulic system.

6. Install New Seals Apply a light coating of hydraulic fluid to the new seals before installation. This helps to prevent damage during assembly. Carefully position the new seals in their respective grooves, ensuring they fit securely.

7. Reassemble the Cylinder Reinsert the piston and rod into the cylinder. Follow the disassembly order to reattach all components, ensuring that everything is tightened to the manufacturer’s specifications.

8. Test the System Once the cylinder is reassembled and reattached, slowly reapply hydraulic pressure and check for leaks. Monitor the system closely during the initial operation.

Conclusion

Replacing seals in hydraulic cylinders is a crucial maintenance task that can significantly prolong the life of the cylinder and the machinery it serves. Regular inspections and timely replacements can prevent leaks, enhance performance, and reduce the risk of failure. By understanding the signs of seal damage and following the proper replacement procedures, operators can ensure their hydraulic systems remain efficient and reliable.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories