Nov . 15, 2024 01:37 Back to list

replacing seals hydraulic cylinder

Replacing Seals in a Hydraulic Cylinder A Comprehensive Guide

Hydraulic cylinders are crucial components in various machinery and equipment, offering the necessary force and motion for numerous applications. Over time, the seals within these cylinders can wear out due to continuous pressure, temperature fluctuations, and contamination. Replacing seals in a hydraulic cylinder is essential for maintaining optimal performance and ensuring the longevity of the equipment. This article provides a detailed guide on how to replace seals in a hydraulic cylinder effectively.

Understanding the Importance of Seals

Seals play a vital role in hydraulic systems by preventing fluid leakage and maintaining pressure within the cylinder. They also protect internal components from dirt, dust, and moisture, which can cause significant damage. A worn or damaged seal can lead to decreased efficiency, increased operational costs, and potential failure of the hydraulic system.

Tools and Materials Needed

Before embarking on the seal replacement process, it’s essential to gather the necessary tools and materials. Typically, you will need

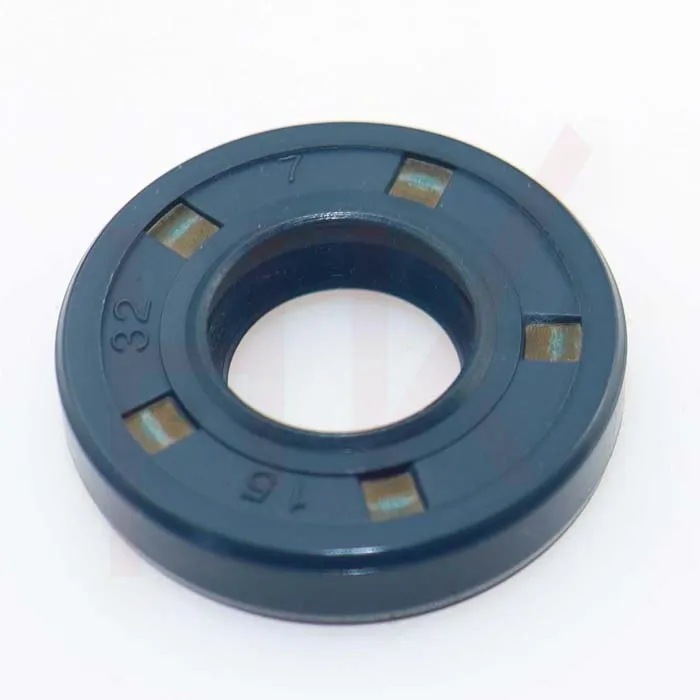

1. Replacement seals (ensure they are the correct size and type) 2. A seal removal tool or pick 3. A clean work area 4. Hydraulic oil for refilling 5. Torque wrench 6. Safety goggles and gloves

Step-by-Step Process

1. Safety First Ensure that the hydraulic cylinder is depressurized. Disconnect the power source and wear appropriate safety gear to protect against any unexpected discharges of hydraulic fluid.

replacing seals hydraulic cylinder

2. Remove the Cylinder Detach the hydraulic cylinder from the machinery, taking note of the connections. Use caution to avoid damaging any components.

3. Disassemble the Cylinder Carefully remove the end caps and any other components securing the seals. This step may require a torque wrench to ensure you do not damage the threads.

4. Remove Old Seals Use a seal removal tool or pick to extract the worn seals. Be cautious not to scratch the cylinder’s surface, as this can lead to new seal failure.

5. Clean the Cylinder Thoroughly clean the internal surfaces of the cylinder to remove dirt and debris. A clean surface is crucial for the effective sealing of new seals.

6. Install New Seals Carefully place the new seals into their designated grooves. Ensure they are seated evenly to prevent leakage.

7. Reassemble the Cylinder Reattach the end caps and other components, ensuring that all parts are tightened to the manufacturer’s specifications.

8. Reinstall and Test Reinstall the hydraulic cylinder onto the machinery. Reconnect all hoses and fittings, refill with hydraulic fluid, and perform a pressure test to check for leaks.

Conclusion

Regular maintenance of hydraulic cylinders, including seal replacement, is vital for optimal performance. By following these steps, you can ensure that your hydraulic system operates efficiently and effectively, prolonging its lifespan and enhancing overall productivity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories