Nov . 06, 2024 05:12 Back to list

Steps for Replacing Seals in Hydraulic Cylinders Efficiently and Effectively

Replacing Seals in Hydraulic Cylinders A Comprehensive Guide

Hydraulic cylinders are essential components in various machinery, providing powerful linear motion by converting hydraulic energy into mechanical work. Over time, the seals within these cylinders can wear out due to pressure fluctuations, environmental conditions, and regular usage. When this happens, it's crucial to replace the seals to maintain the efficiency and safety of the hydraulic system. This article outlines the steps involved in replacing seals in hydraulic cylinders and provides insights into best practices.

Understanding the Importance of Seals

The seals in a hydraulic cylinder serve multiple functions they prevent hydraulic fluid from leaking out of the cylinder, keep contaminants from entering, and maintain the pressure necessary for the cylinder to function effectively. If a seal wears out or becomes damaged, it can lead to oil leaks, which not only reduces the efficiency of the system but can also lead to environmental concerns and safety hazards.

Tools and Materials Required

Before attempting to replace seals in a hydraulic cylinder, gather the necessary tools and materials

1. Tools - Wrenches and sockets - Screwdrivers - Pliers - Hydraulic jack or press - Seal puller - Measuring tools (calipers, micrometer)

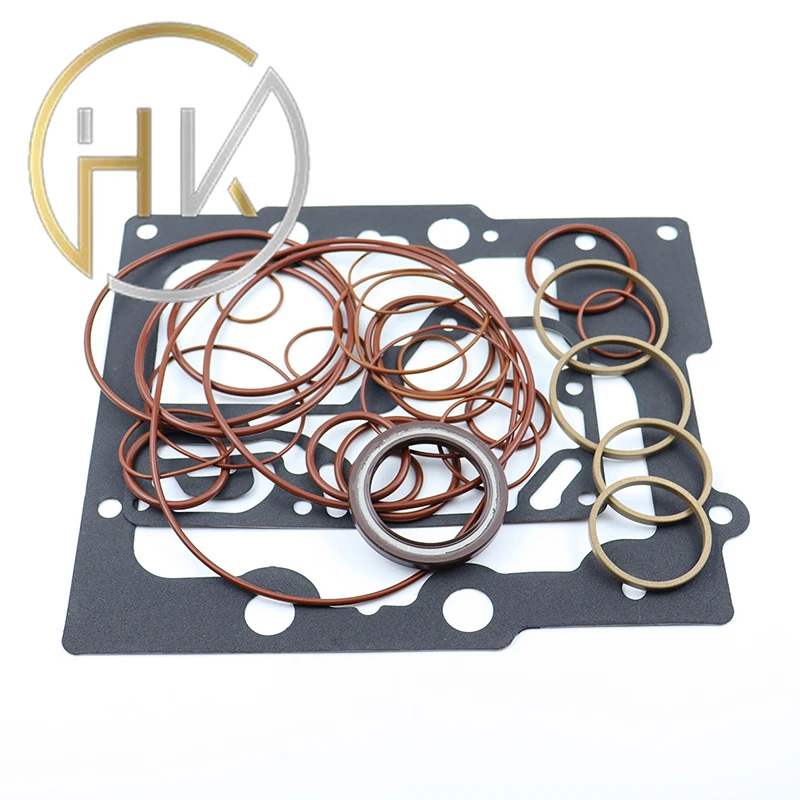

2. Materials - Replacement seal kit (ensure it’s compatible with your hydraulic cylinder) - Hydraulic fluid - Cleaning solvent - Lubricating grease

Step-by-Step Seal Replacement

1. Safety First Before starting the disassembly process, ensure that the system is depressurized. Disconnect the hydraulic lines and relieve any built-up pressure. Always wear appropriate personal protective equipment (PPE).

2. Remove the Cylinder from the System Depending on the hydraulic system design, you may need to detach the cylinder from the machine. Use a hydraulic jack to help lift and remove it safely.

replacing seals hydraulic cylinder

3. Disassemble the Cylinder Carefully open the hydraulic cylinder. This typically involves removing end caps and sliding out the piston. Take note of the orientation and order of parts for reassembly.

4. Inspect Components Check the cylinder barrel and piston for any signs of wear, scratches, or damage. Clean all components thoroughly using a cleaning solvent to remove dirt and debris.

5. Remove Old Seals Use a seal puller or other suitable tool to carefully remove the old seals. Be cautious not to damage the cylinder or other components during this step.

6. Install New Seals Before installing the new seals, compare them with the old ones to ensure correct sizing. Lubricate the seals with hydraulic fluid to ease installation. Carefully place the new seals into their designated grooves, ensuring they are secure and seated properly.

7. Reassemble the Cylinder With the new seals in place, reinsert the piston and reattach the end caps. Ensure all components are aligned correctly to prevent any mechanical issues.

8. Reinstall the Cylinder Place the hydraulic cylinder back into the system, reconnect all hydraulic lines, and ensure everything is tightened to the manufacturer’s specifications.

9. Refill and Bleed the System Once everything is reassembled, refill the system with hydraulic fluid. Bleed the system to remove any air pockets by following the specific bleeding procedures for your equipment.

10. Test the System After completing the installation, operate the hydraulic system at a low pressure to check for leaks or irregularities. Monitor the system closely during the initial operation to ensure that everything functions smoothly.

Conclusion

Replacing seals in hydraulic cylinders is a critical maintenance task that can significantly affect the performance and longevity of hydraulic machinery. By following the steps outlined above and adhering to safety procedures, operators can ensure that their hydraulic systems remain efficient and reliable. Regular inspections and timely seal replacements will not only prevent costly downtime but also safeguard the machine’s overall performance and environmental compliance. Always consult the manufacturer’s guidelines or a professional technician if unsure about any aspect of the process.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories