Nov . 05, 2024 14:24 Back to list

replacing seals hydraulic cylinder

Replacing Seals in Hydraulic Cylinders A Comprehensive Guide

Hydraulic cylinders are crucial components used in a wide variety of industrial and automotive applications. They allow for the conversion of hydraulic energy into linear motion, enabling machinery to perform tasks such as lifting, pushing, and pulling. One of the common issues that can hinder the performance of hydraulic cylinders is seal wear or damage. This article provides a comprehensive overview of replacing seals in hydraulic cylinders, outlining the necessary steps and considerations.

Understanding Hydraulic Cylinder Seals

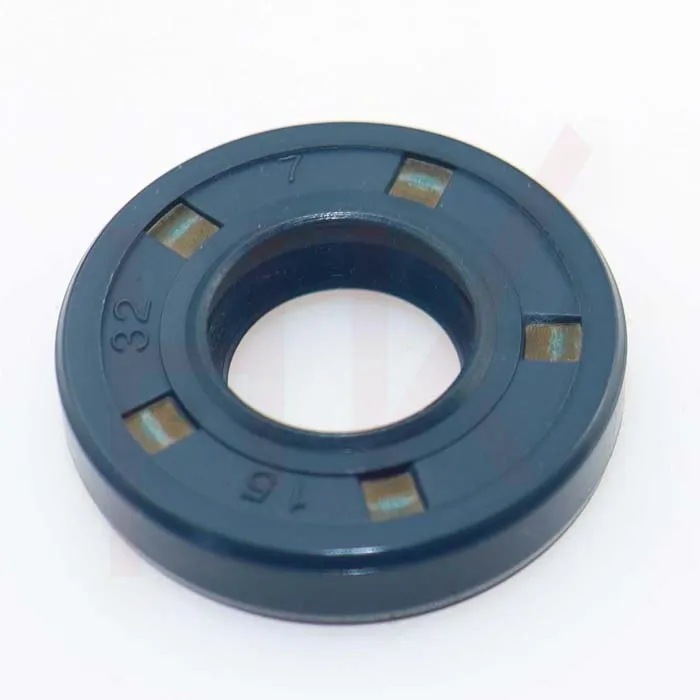

Hydraulic cylinder seals are designed to prevent the leakage of hydraulic fluid from the cylinder and to protect internal components from contamination. These seals are subjected to extreme pressures and various operating conditions, leading to wear and tear over time. Common types of seals include O-rings, piston seals, and rod seals. Recognizing the signs of seal failure (such as oil leaks or reduced performance) is crucial for timely maintenance.

Tools and Materials Needed

Before beginning the seal replacement process, gather the necessary tools and materials

1. Tools Wrenches, screwdrivers, seal pullers, pliers, and torque wrenches. 2. Materials Replacement seals (specific to the cylinder model), hydraulic fluid, and cleaning supplies (rags, solvents).

Step-by-Step Seal Replacement Process

1. Preparation and Safety Measures Ensure that you are wearing appropriate safety gear. It’s essential to depressurize the hydraulic system before starting the work to prevent accidents and injuries.

replacing seals hydraulic cylinder

2. Remove the Cylinder Disconnect the hydraulic cylinder from the machinery. This may involve detaching hoses and any mounting hardware. Take care to label parts for reinstallation.

3. Disassemble the Cylinder Once the cylinder is removed, carefully disassemble it. This generally involves removing the end caps and the piston. Use a seal puller to take out the old seals, being cautious not to damage the cylinder’s surfaces.

4. Clean the Components Thoroughly clean all components of the hydraulic cylinder. Remove any dirt, debris, and residual hydraulic fluid. Inspect the cylinder walls and other parts for scratches or damage.

5. Install New Seals Carefully install the new seals in their respective grooves. Ensure that the seals are compatible with the hydraulic fluid being used. It’s important to apply a thin layer of hydraulic fluid to the seals to facilitate easier installation and prevent tearing.

6. Reassemble the Cylinder Once the new seals are in place, reassemble the hydraulic cylinder. Make sure to follow the manufacturer's specifications for torque settings to avoid any issues.

7. Test the Cylinder After reinstallation, reconnect the hydraulic hoses and reattach the cylinder to the machinery. Before operating, check for leaks around the new seals by running the system at low pressure first.

Conclusion

Replacing seals in hydraulic cylinders is a straightforward process that can significantly enhance the performance and lifespan of your hydraulic system. Regular maintenance and timely seal replacement are essential practices that prevent costly repairs and downtime. Remember to keep an eye on the performance of your hydraulic equipment and address any seal-related issues as they arise. Proper care and diligence will ensure your hydraulic systems operate efficiently for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories