Nov . 05, 2024 04:49 Back to list

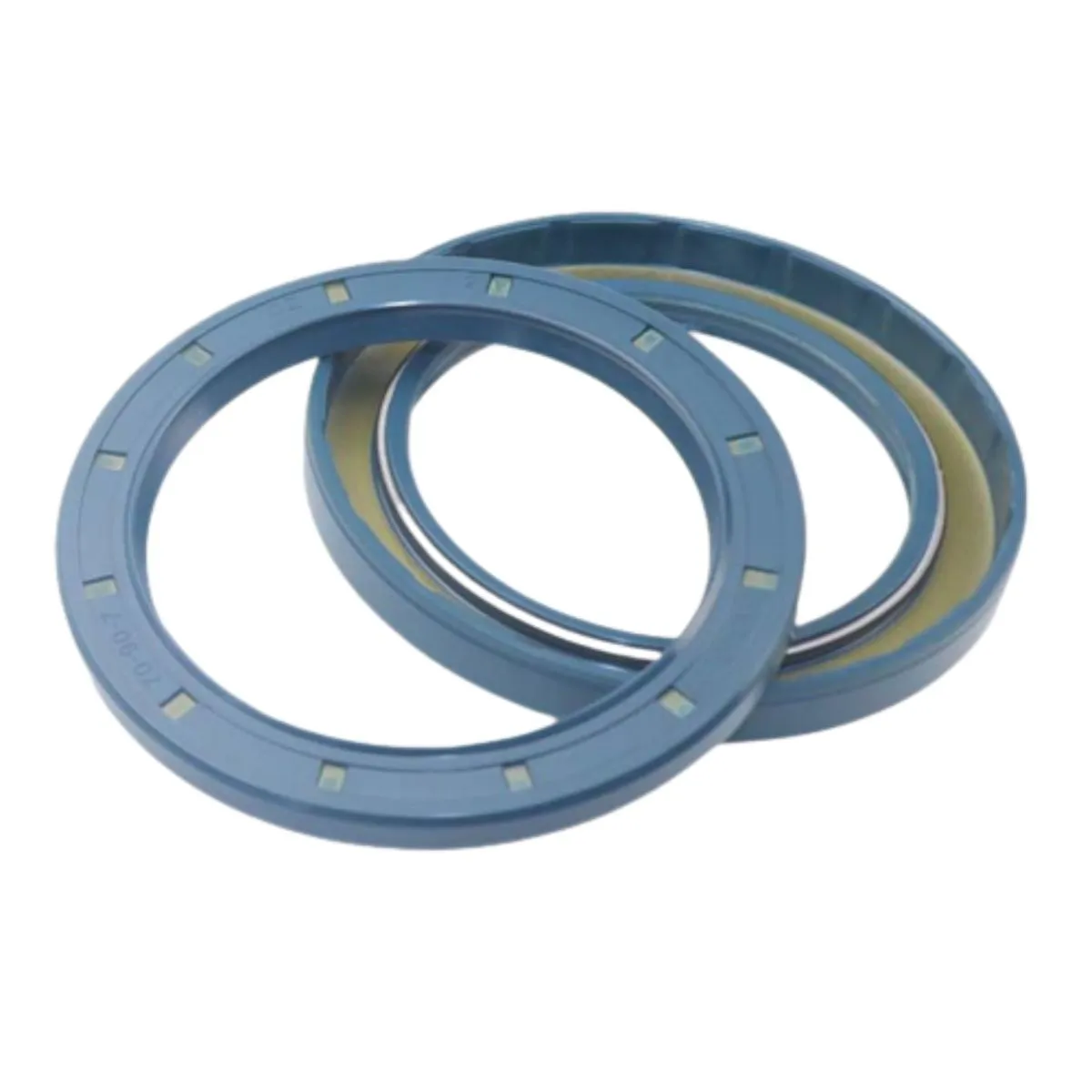

replacing seals hydraulic cylinder

Replacing Seals in Hydraulic Cylinders A Comprehensive Guide

Hydraulic cylinders are vital components in various industrial applications, providing the power needed to perform heavy lifting and precise movements. Over time, the seals within these cylinders can wear down due to constant pressure, temperature fluctuations, and exposure to contaminants. Replacing these seals is essential to ensure the efficient operation and longevity of hydraulic systems. This article outlines the importance of seal replacement, the signs that indicate a need for replacement, and a step-by-step guide on how to effectively replace seals in hydraulic cylinders.

Importance of Seal Replacement

Seals play a crucial role in hydraulic cylinders by preventing the leakage of hydraulic fluid. They also protect the internal components from dirt, dust, and moisture, which can lead to premature wear and failure. When seals fail, it can result in significant fluid loss, reduced efficiency, and increased operational costs. Moreover, hydraulic fluid leaks can pose environmental hazards and workplace safety concerns. Regular maintenance, including seal replacement, helps to avoid these issues, ensuring that hydraulic systems function optimally.

Signs of Worn Seals

Identifying worn or damaged seals early can prevent more extensive and costly repairs. Here are some common signs indicating that seal replacement may be necessary

1. Fluid Leaks The most apparent sign of seal failure is visible hydraulic fluid leaks around the cylinder. If you notice puddles of fluid or wet spots, it’s time to inspect the seals.

2. Reduced Performance A hydraulic cylinder that operates slower than usual or struggles to lift loads can indicate that the seals are worn out. Inadequate sealing can lead to a drop in pressure, affecting performance.

3. Increased Noise Unusual sounds, such as grinding or whining noises during operation, may indicate seal degradation, which could be allowing air or contaminants into the system.

4. Visual Inspection Regularly inspecting seals for cracks, deformation, or signs of wear can help identify potential problems before they escalate.

Step-by-Step Guide to Replacing Seals

replacing seals hydraulic cylinder

Replacing seals in a hydraulic cylinder can be a straightforward task if you follow these steps

1. Safety Precautions Before starting, ensure the hydraulic system is depressurized. Disconnect power sources and wear appropriate personal protective equipment (PPE).

2. Disassembly Carefully remove the hydraulic cylinder from its mounting. Take note of the assembly order and any other components that may need attention. Clean the exterior of the cylinder to prevent contaminants from entering.

3. Remove the Old Seals Once disassembled, carefully remove the old seals using a seal removal tool or a flat-head screwdriver. Take care not to scratch the cylinder bore or rod during this process.

4. Inspect the Cylinder Examine the cylinder bore and rod for any scratches or damage. Use a fine-grit sandpaper or honing tool to smooth out minor imperfections.

5. Clean the Sealing Surfaces Thoroughly clean the grooves where the new seals will fit. Use a lint-free cloth and an appropriate solvent to remove any residue from old seals and hydraulic fluid.

6. Install New Seals Carefully install the new seals, ensuring they fit snugly in their respective grooves. Apply a thin layer of hydraulic oil to the seals to facilitate installation and prevent damage.

7. Reassemble the Cylinder Reassemble the cylinder in the reverse order of disassembly. Ensure all components are correctly aligned and tightened to the manufacturer’s specifications.

8. Test the System Reinstall the hydraulic cylinder, reconnect all hydraulic lines, and refill the system with hydraulic fluid. Slowly pressurize the system to check for leaks and proper operation.

Conclusion

Replacing seals in hydraulic cylinders is a critical maintenance task that ensures the reliability and efficiency of hydraulic systems. By recognizing the signs of seal wear and following a systematic replacement process, operators can maintain optimal performance and mitigate potential issues. Investing time and resources in regular maintenance not only extends the lifespan of hydraulic equipment but also enhances workplace safety and productivity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories