Aug . 29, 2024 06:37 Back to list

Replacing Seals in a Hydraulic Cylinder

Replacing Seals in a Hydraulic Cylinder

Hydraulic cylinders are essential components in various industrial machines, performing tasks that involve lifting, pushing, or pulling heavy loads. Over time, seals within these cylinders can wear out due to friction, heat, and the pressure of hydraulic fluid. Replacing these seals is a critical maintenance task that ensures the smooth operation and longevity of the hydraulic system.

Understanding the Importance of Seals

Seals in a hydraulic cylinder serve several crucial functions. They prevent hydraulic fluid from leaking out of the cylinder, which not only maintains the pressure necessary for operation but also protects the cylinder from contamination. A compromised seal can lead to reduced efficiency, increased fluid consumption, and potential damage to the cylinder itself. Thus, regular inspection and timely replacement of seals is necessary for optimal performance.

Identifying When to Replace Seals

It is essential for operators to recognize the signs that seals need replacing. Common indicators include visible leaks around the cylinder, decreased performance or responsiveness, and unusual sounds during operation. If you notice any of these symptoms, it is wise to conduct a thorough inspection and consider replacing the seals as soon as possible to avoid further damage.

Steps for Replacing Seals

Replacing seals in a hydraulic cylinder is a process that can be undertaken by those with some technical expertise. Here’s a step-by-step guide

1. Safety First Before beginning any maintenance work, ensure that the hydraulic system is depressurized. Disconnect the hydraulic lines and ensure you are equipped with personal protective equipment (PPE) such as gloves and goggles.

replacing seals in a hydraulic cylinder

2. Remove the Cylinder Detach the hydraulic cylinder from the machinery. This often involves unbolting it and carefully lifting it away.

3. Disassemble the Cylinder Using appropriate tools, disassemble the hydraulic cylinder. Take care to keep track of all components, as they will need to be reassembled later.

4. Inspect Components While you have the cylinder disassembled, inspect all internal components for wear and damage. This includes the piston, rod, and cylinder barrel. Sometimes, other components may also need replacement.

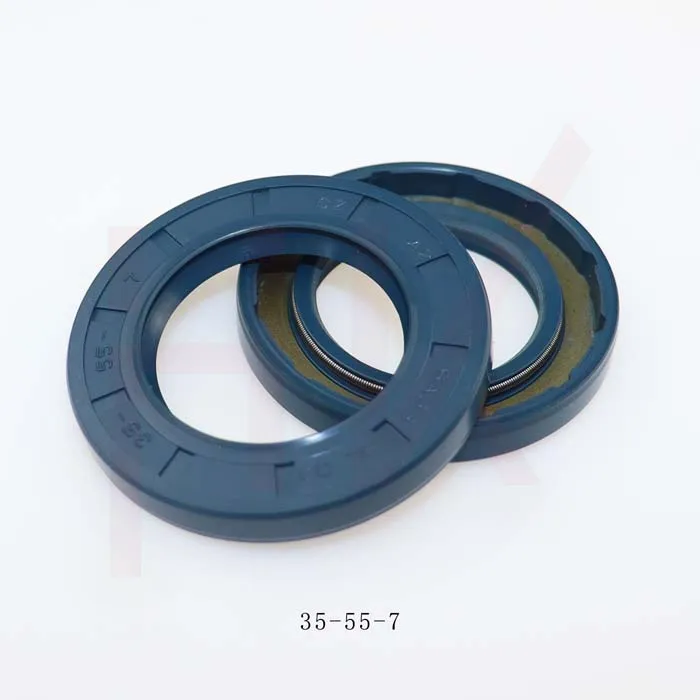

5. Replace the Seals Carefully remove the old seals and clean the sealing surfaces. Then, install the new seals, ensuring they are seated correctly to prevent future leaks. It’s crucial to use seals that are compatible with your specific hydraulic fluid and application.

6. Reassemble the Cylinder After replacing the seals, carefully reassemble the cylinder. Make sure all parts are aligned correctly and that no components are damaged during the reassembly process.

7. Test the System Once reassembled, reattach the cylinder to the machinery and reconnect hydraulic lines. Conduct tests to ensure that the cylinder operates smoothly and without leaks.

Conclusion

Replacing seals in a hydraulic cylinder is an important maintenance task that can prolong the life of your equipment and maintain operational efficiency. By recognizing the signs of seal wear and understanding the replacement process, operators can ensure their hydraulic systems remain reliable and effective, ultimately saving time and resources in the long run. Regular maintenance, including seal replacement, is key to preventing costly repairs and downtime.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories