Sep . 01, 2024 09:21 Back to list

Replacing Seals in a Hydraulic Cylinder

Replacing Seals in a Hydraulic Cylinder

Hydraulic cylinders play a crucial role in various machinery, providing the force needed for lifting, pushing, and pulling. One of the most common issues that can arise in the operation of hydraulic systems is the leakage of hydraulic fluid due to worn or damaged seals. Replacing seals in a hydraulic cylinder is an essential maintenance task that can extend the lifespan of the equipment and ensure optimal performance.

The process of replacing seals begins with disassembling the hydraulic cylinder. First, ensure that the system is depressurized to avoid any accidents. Safety should always be the top priority when working with hydraulic systems. Once the system is safe, the cylinder can be removed from the machine. Using the appropriate tools, carefully unscrew and disassemble the cylinder components, paying attention to the order of disassembly, as it will be vital for reassembly.

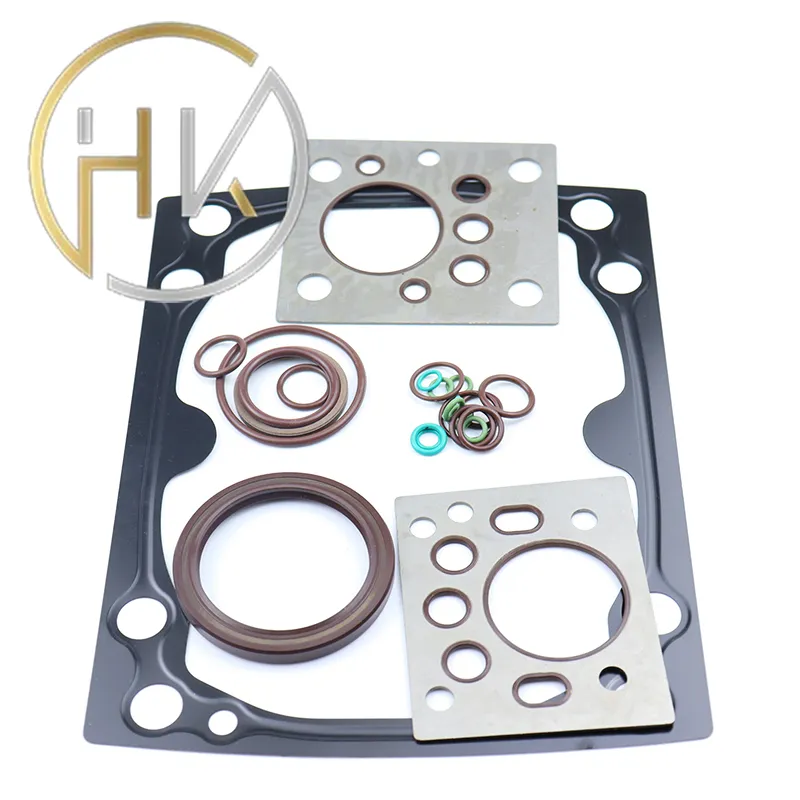

After removing the cylinder, inspect the existing seals for signs of wear, such as cracks, tears, or deformation. Typically, seals are made of materials such as rubber, polyurethane, or PTFE, which can break down over time due to exposure to high pressures, temperatures, and the fluid itself. It’s important to measure the old seals accurately to ensure that the replacements are the correct size.

replacing seals in a hydraulic cylinder

When selecting new seals, consider the application and the type of hydraulic fluid used. Using seals that are compatible with the fluid type will prevent premature degradation and ensure a longer lifespan. Once you have acquired the necessary replacement seals, carefully fit them into their respective grooves on the piston and cylinder.

Reassembling the hydraulic cylinder involves reversing the disassembly process. Make sure to lubricate the seals lightly to facilitate proper seating and prevent damage during assembly. Carefully align all components and securely fasten the cylinder to avoid any issues when it is pressurized again.

After reassembly, reconnect the hydraulic cylinder to the system, ensuring all connections are tight and secure. Finally, test the system to check for any leaks and ensure that the cylinder operates smoothly. By properly replacing the seals, you can significantly enhance the performance and reliability of the hydraulic system, minimizing downtime and costly repairs in the future. Regular maintenance, including seal replacement, is key to ensuring that hydraulic cylinders function reliably and efficiently for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories