Aug . 14, 2024 22:12 Back to list

Replacement Options for 25x47mm Oil Seals to Ensure Optimal Equipment Performance and Longevity

Understanding the 25x47x7 Oil Seal Importance and Applications

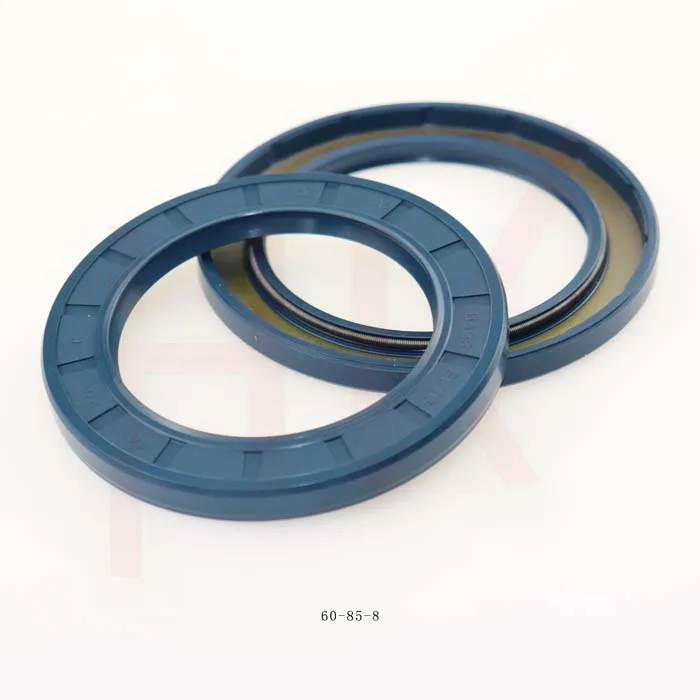

Oil seals, also known as oil seals or rotary seals, play a crucial role in various mechanical applications by preventing the leakage of lubricants and keeping contaminants out of the machinery. Among the various dimensions and specifications available in the market, the 25x47x7 oil seal has gained significant attention due to its versatility and effectiveness in numerous applications. In this article, we will delve into the specifications, manufacturing materials, applications, and installation tips related to the 25x47x7 oil seal.

Specifications

The numbers in the oil seal designation represent its dimensions the first number, 25, denotes the inner diameter (ID) in millimeters, the second number, 47, signifies the outer diameter (OD) in millimeters, and the last number, 7, indicates the thickness of the seal. This specific size makes it suitable for a variety of machinery and moving parts. Typically, oil seals are designed to function under varying pressure and temperature conditions, making them reliable in demanding environments.

Manufacturing Materials

Oil seals are manufactured from a range of materials, each chosen for its specific properties. Common materials include rubber, elastomers, or thermoplastics. For the 25x47x7 oil seal, Nitrile rubber (NBR) is one of the most prevalent choices, given its excellent resistance to oil and temperature extremes. Other materials such as Viton provide superior performance in high-temperature environments. The choice of material directly affects the seal’s performance, durability, and the specific type of fluids it can contain.

Applications

The applications of the 25x47x7 oil seal are vast, encompassing a variety of sectors including automotive, industrial machinery, and agricultural equipment. In the automotive industry, these seals are commonly used in engine crankshafts, transmission areas, and other crucial components where oil retention and contamination prevention are critical. In industrial machinery, they are employed in pumps, gearboxes, and hydraulic systems, ensuring smooth operation and extending the lifespan of equipment.

Agriculture also benefits from this particular oil seal, as farm machinery often endures harsh conditions that can lead to wear and tear. By utilizing a robust oil seal like the 25x47x7, operators can maintain the efficiency of their equipment while minimizing the risk of costly downtimes.

25x47x7 oil seal

Installation Tips

Proper installation of an oil seal is vital to ensure its functionality and longevity. Here are some tips for a successful installation of the 25x47x7 oil seal

1. Surface Preparation Ensure that the shaft and housing are clean, free of debris, and smooth. Any imperfections can lead to premature failure of the seal.

2. Lubrication Lightly lubricate the seal and the shaft to facilitate sliding during installation and to help it seat properly.

3. Alignment Carefully align the oil seal with the shaft to prevent twisting or damage. Misalignment can result in leaks and compromised performance.

4. Proper Seating Use a seal installer or a similar tool to press the seal evenly into place. Ensure that it is seated flush against the housing to eliminate gaps.

5. Inspection After installation, inspect the seal to make sure it fits correctly and looks undamaged. This will help ensure optimal performance.

Conclusion

The 25x47x7 oil seal is a vital component in various machines and vehicles, preventing lubricant leaks and protecting critical internal parts from contaminants. With the right material choice, application, and installation method, users can achieve optimal performance and extend the service life of their equipment. Understanding the significance and proper handling of this oil seal can lead to improved efficiency and reduced maintenance costs in operational settings.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories