Feb . 18, 2025 05:12 Back to list

pu wiper seal

Expertise in this field reveals the environmental advantages PU wiper seals offer. Unlike other materials that might degrade and release harmful chemicals, polyurethane is known for its compliance with a variety of environmental regulations due to its stability and inert properties. This makes PU wiper seals a sustainable choice, aligning with the growing global emphasis on environmentally conscious manufacturing practices. To ensure maximum effectiveness, it is crucial to partner with established manufacturers who uphold rigorous quality standards. Look for endorsements of compliance with international standards like ISO9001, which indicate a commitment to sustained quality development. Engaging with manufacturers who provide in-depth product specifications, technical support, and comprehensive after-sales service also reinforces trust and reliability. Real-world experience underscores the necessity of proper installation and maintenance of PU wiper seals. Skilled technicians understand the delicate nature of seal fitment and the possible stresses imposed during operation. Regular inspections and maintenance routines can pre-emptively identify wear, ensuring timely replacements that prevent unexpected failures. Thus, ongoing training and skill development related to the handling of these seals is an investment in operational excellence. In conclusion, PU wiper seals epitomize reliability and efficiency, supported by expert design and robust material properties. Their capacity to safeguard machinery, optimize performance, and support environmental goals positions them as a cornerstone in industrial applications. For businesses seeking a seal that embodies excellence and dependability, PU wiper seals are an unparalleled choice, wielding influence not only in operational success but also in advancing technological and environmental progress.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

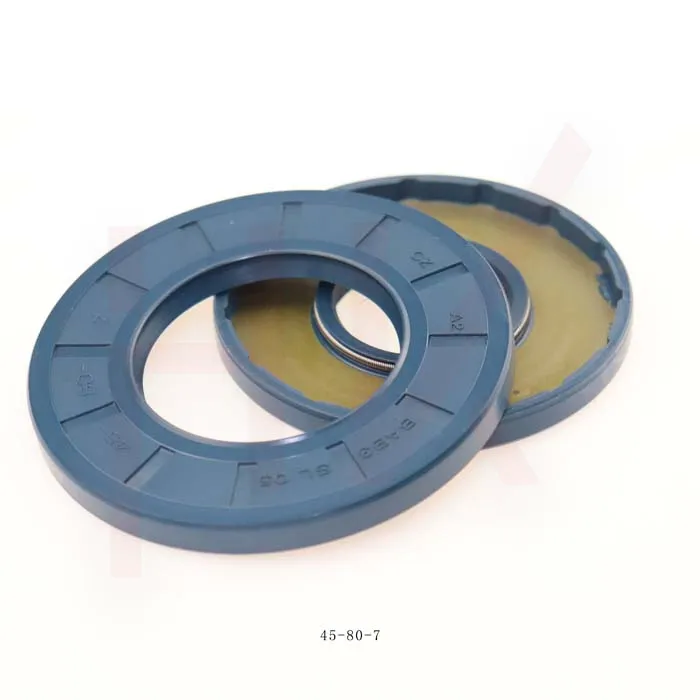

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories