Nov . 22, 2024 16:45 Back to list

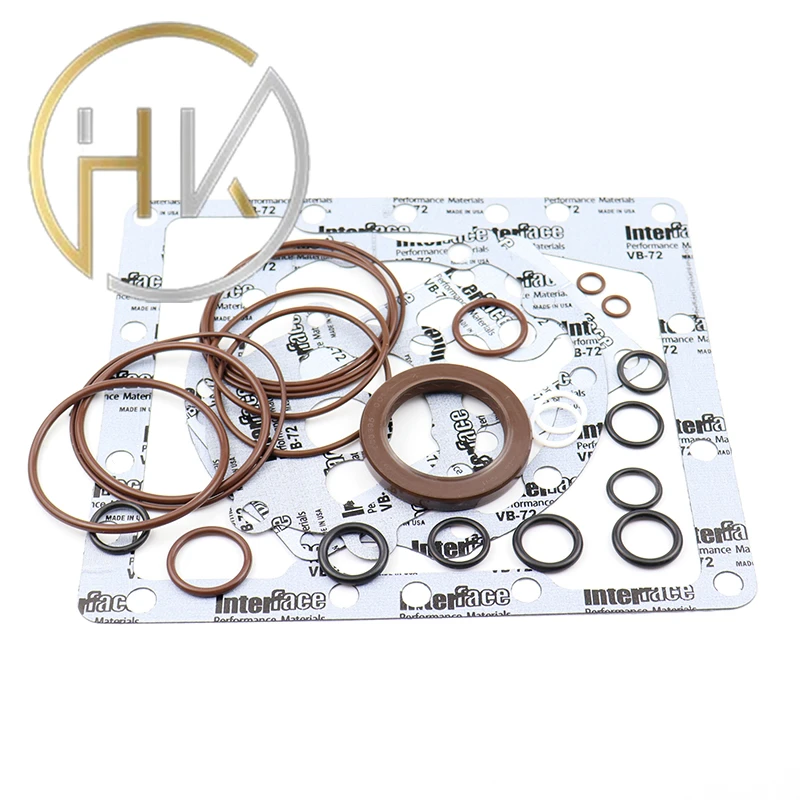

pump seal oil

Understanding Pump Seal Oil Importance and Applications

In various industrial applications, pumps play a critical role in the efficient movement of liquids, gases, and slurries. One crucial component in ensuring the longevity and effective performance of these pumps is the seal oil, commonly referred to as pump seal oil. This specialized oil acts as a lubricant and a barrier, preventing leakage and protecting components from wear and corrosion.

What is Pump Seal Oil?

Pump seal oil is a lubricant specifically designed to lubricate the seals within pumping systems. Its primary function is to minimize friction between moving parts, thereby reducing wear and extending the life of the equipment. Additionally, seal oil plays a vital role in forming a barrier that prevents the substance being pumped from leaking into the environment or the surrounding machinery, thus ensuring operational efficiency and safety.

Functions of Pump Seal Oil

1. Lubrication One of the primary functions of pump seal oil is to provide lubrication for the mechanical seals. This lubrication reduces friction and heat buildup, which can lead to seal failure if not adequately managed.

2. Leak Prevention Pump seal oil acts as a barrier to minimize leaks, helping to maintain the integrity of the system while protecting the environment from contamination.

3. Cooling In many pumping systems, seal oil assists in dissipating heat generated by friction or environmental factors. By maintaining optimal temperature ranges, pump seal oil contributes to extending the life of the seals and the overall pump system.

4. Corrosion Resistance Many pump seal oils are formulated with additives that offer corrosion protection. This is particularly important in harsh environments where pumps may be exposed to corrosive substances.

5. Contaminant Removal Over time, contaminants such as dirt, debris, and particulates can be introduced into a pumping system. Pump seal oil can help trap and remove these contaminants, preventing them from causing damage to the mechanical components.

Types of Pump Seal Oil

Pump seal oils come in various formulations, tailored to meet specific operational demands. Common types of pump seal oils include

pump seal oil

- Mineral Oils These are derived from refining crude oil and are often used for general lubrication and sealing applications. They are cost-effective and widely available.

- Synthetic Oils Synthetic pump seal oils are engineered for superior performance, often providing better temperature stability, lower volatility, and enhanced protection against oxidation and thermal degradation. They are ideal for extreme conditions where traditional oils may fail.

- Biodegradable Oils In industries where environmental concerns are paramount, biodegradable pump seal oils are developed. These oils break down naturally, minimizing ecological impact in the event of a leak or spill.

Choosing the Right Pump Seal Oil

Selecting the appropriate pump seal oil is crucial for ensuring optimal pump performance. Factors to consider include

1. Operating Temperature Assess the temperature range in which the pump will operate. High temperatures may require synthetic oils with higher thermal stability.

2. Chemical Compatibility Ensure the seal oil is compatible with the fluid being pumped, as certain chemicals may degrade the seal oil or vice versa.

3. Environmental Regulations Consider the environmental impact and regulatory compliance when selecting oils, especially in sensitive environments.

4. Manufacturer Recommendations Always refer to the pump manufacturer’s specifications and guidelines when choosing the seal oil to ensure compatibility and efficiency.

Conclusion

In summary, pump seal oil is an essential component in maintaining the functionality and longevity of pumping systems. By providing lubrication, preventing leaks, and protecting against corrosion, seal oil ensures that pumps operate efficiently in various industrial applications. Proper selection and maintenance of pump seal oil not only enhance performance but also contribute to a safer and more environmentally friendly operation. Understanding the importance and functions of pump seal oil can lead to better decision-making and more effective maintenance strategies in industrial settings.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories