Oct . 02, 2024 18:12 Back to list

price of oil seal

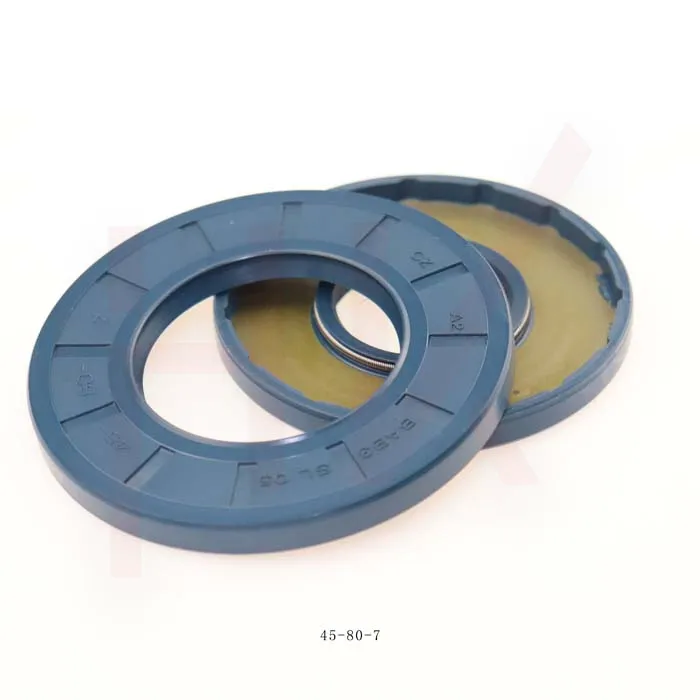

The Price of Oil Seals An Overview

Oil seals play a crucial role in various mechanical systems, preventing the leakage of lubricants and contaminants from entering machinery. These components, though often overlooked, are vital for the efficient operation of engines, pumps, and other equipment. Understanding the factors that influence the price of oil seals can help consumers and manufacturers make informed purchasing decisions.

One primary factor affecting the price of oil seals is the raw materials used in their production. Typically made from elastomers like nitrile rubber, fluorocarbon, or polyurethane, the price of these materials fluctuates based on global supply and demand. For instance, a surge in oil prices can lead to increases in the costs of synthetic rubber. This scenario directly impacts the price of oil seals, as manufacturers must adjust their prices to reflect the higher costs of production.

Additionally, the manufacturing process plays a significant role in pricing. High-precision oil seals require advanced technology and specialized equipment, which can drive up production costs. Companies that invest in better technology often produce more durable and efficient seals but at a higher price point. Therefore, the balance between quality and cost is a critical consideration for consumers when selecting oil seals.

price of oil seal

Another influence on oil seal pricing comes from market competition. As the industry grows, various manufacturers strive to offer competitive prices. While this competition can lead to lower prices for consumers, it can also result in variable quality. Consumers must be cautious to avoid lower-cost options that may not provide the durability and reliability needed in their applications. Investing in reputable brands might come at a premium, but it often pays off through reduced maintenance costs and longer service life.

Furthermore, geographical factors can determine the local availability and distribution costs of oil seals. Regions with strong manufacturing bases or easy access to raw materials may see lower prices due to reduced transportation costs. Conversely, remote or economically challenged areas might experience inflated prices due to logistical challenges. Understanding these dynamics can help buyers negotiate better deals or choose the right suppliers.

Lastly, the growing trend towards sustainability and eco-friendly products is beginning to shape the pricing landscape of oil seals. As manufacturers invest in greener materials and processes, prices may reflect these innovations. Consumers increasingly seek products that align with their sustainability goals, creating a new market for environmentally friendly oil seals, albeit often at a higher cost.

In conclusion, the price of oil seals is influenced by a confluence of material costs, manufacturing processes, market competition, geographical factors, and sustainability trends. By considering these elements, consumers can make informed choices, ensuring they invest not only in cost-effective but also high-quality and reliable oil seal solutions.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories