Nov . 18, 2024 18:49 Back to list

Understanding TCV Oil Seals and Their Applications in Machinery and Equipment

Understanding Oil Seal TCV Applications and Importance

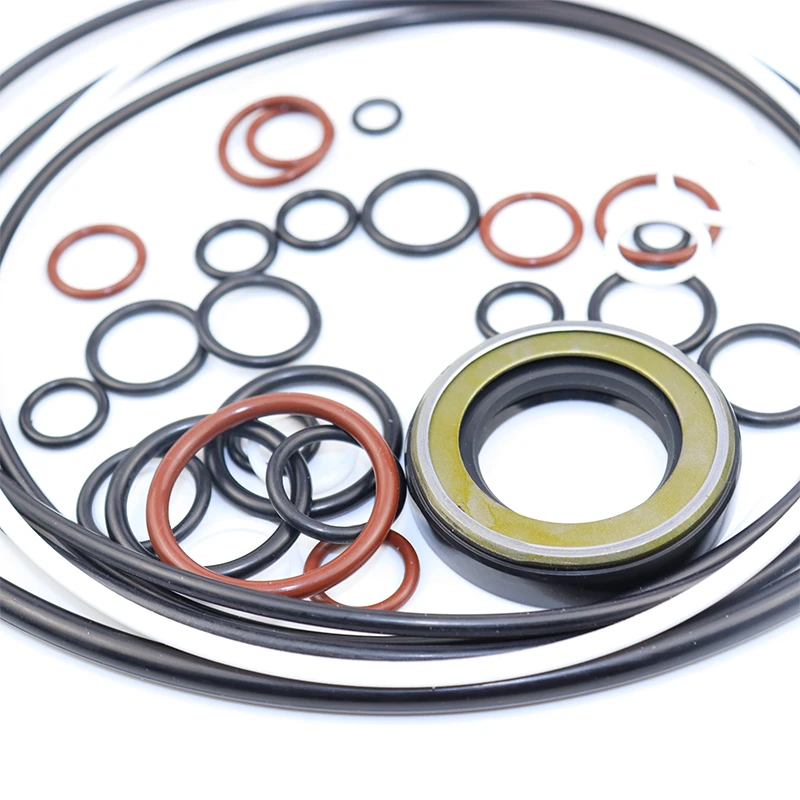

Oil seals play a critical role in a variety of machinery and engines, acting as barriers to prevent oil leakage and contamination. Among the different types of oil seals, the TCV (Triple Contact Vulcanized) oil seal stands out for its unique design and superior performance in demanding environments. This article delves into the essential features, applications, and benefits of TCV oil seals.

Understanding Oil Seal TCV Applications and Importance

One of the main materials used in the manufacturing of TCV oil seals is elastomer. The elastic properties of this material allow the seal to maintain flexibility, making it adaptable to changes in temperature and pressure. Additionally, the vulcanization process strengthens the elastomer, improving its durability and resistance to wear. This ensures that TCV oil seals perform reliably even under harsh operating conditions, extending the service life of both the seal and the machinery it protects.

oil seal tcv

TCV oil seals are widely used in various industries, including automotive, aerospace, manufacturing, and construction. In automotive applications, TCV oil seals are employed in engines, transmissions, and differential systems. They are instrumental in preventing oil leaks that can lead to reduced efficiency and potential damage to engine components. In aerospace, these seals are critical for ensuring the integrity of fuel systems in aircraft, where even minor leaks can have significant consequences.

The importance of TCV oil seals extends beyond just preventing leaks; their role in maintaining the overall health of machinery cannot be overstated. By keeping lubricants inside and contaminants out, TCV seals contribute to improved performance, enhanced efficiency, and reduced maintenance costs. Machinery that operates with effective sealing solutions tends to have a lower likelihood of breakdowns, which can translate to significant savings for businesses in terms of both repairs and downtime.

Moreover, the environmental impact of TCV oil seals is noteworthy. By minimizing oil leaks and preventing spills, these seals help reduce the risk of environmental contamination. This not only promotes compliance with environmental regulations but also supports sustainability initiatives across various sectors.

In conclusion, TCV oil seals are crucial components that enhance the performance and reliability of machinery across multiple industries. Their unique design, made from durable materials, ensures effective sealing against oils and contaminants. Businesses that utilize TCV oil seals can look forward to improved equipment longevity, operational efficiency, and reduced environmental impact. As technology continues to advance, the development of even more efficient sealing solutions will undoubtedly play a significant role in the future of machinery and equipment maintenance.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories