Sep . 22, 2024 09:21 Back to list

oil seal price

Understanding Oil Seal Prices Factors and Trends

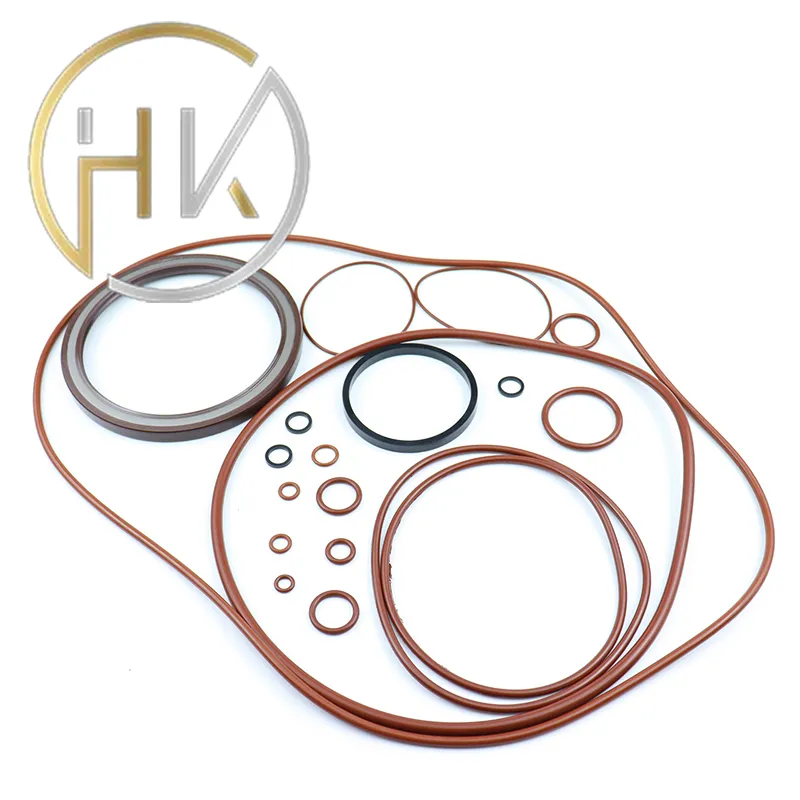

Oil seals play a crucial role in various machinery and automotive applications by preventing the leakage of lubricants and maintaining the integrity of mechanical systems. The price of oil seals is influenced by several factors, including material composition, manufacturing processes, market demand, and economic conditions. Understanding these factors can help consumers make informed decisions while budgeting for maintenance or new machinery.

Material Composition

The type of material used in the production of oil seals significantly impacts their price. Common materials include rubber, silicone, and various thermoplastics. Rubber oil seals are widely used due to their excellent sealing properties and cost-effectiveness. However, specialized materials such as fluorocarbon or polyurethane can be more expensive, as they offer enhanced resistance to extreme temperatures and chemicals. When choosing an oil seal, it’s essential to consider the operating environment, as this will determine the most suitable and cost-effective material.

Manufacturing Processes

The manufacturing process also plays a role in determining oil seal prices. Advanced technologies, such as injection molding and automated production lines, can reduce labor costs and time, leading to lower prices for consumers. However, some manufacturers may opt for traditional production methods for specialty seals, driving up the price due to increased labor and longer production times. Additionally, the scale of production affects unit costs—larger manufacturers can often provide lower prices due to economies of scale.

oil seal price

Market Demand and Economic Conditions

Market dynamics significantly influence pricing as well. In industries experiencing high demand, such as automotive manufacturing or heavy machinery, the competition for high-quality oil seals can drive prices upward. Conversely, during economic downturns, demand may decrease, leading to lower prices. Global events, such as supply chain disruptions or increases in raw material costs, can also impact oil seal pricing. For instance, fluctuations in petroleum prices can affect rubber production costs, subsequently impacting oil seal prices.

Technological Advancements

Innovation in oil seal technology can result in the introduction of new products that provide better performance or durability. Such advancements can justify higher price points in the market as they offer long-term savings through reduced maintenance and replacement costs. Consumers should evaluate the total cost of ownership rather than just the upfront expense when considering more advanced oil seal options.

Conclusion

In summary, the price of oil seals is determined by a multifaceted array of factors, including material composition, manufacturing processes, market demand, and economic conditions. As consumers, it's vital to remain informed about these influences when making purchasing decisions. By considering not just the initial costs but the long-term benefits of superior materials and technologies, buyers can ensure they are making wise investments in their machinery and automotive applications. This holistic approach will assist in navigating the complexities of oil seal prices in the evolving market landscape.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories