Oct . 04, 2024 14:47 Back to list

oil seal price

Understanding Oil Seal Prices Factors and Trends

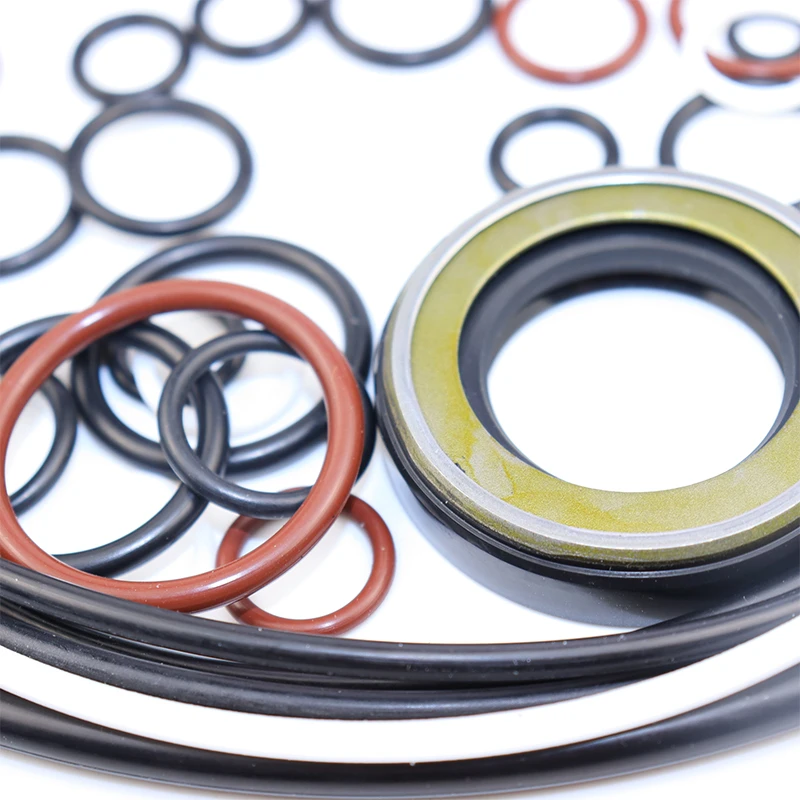

Oil seals, also known as oil rings or oil gaskets, are essential components in various machinery and equipment, primarily used to prevent the leakage of lubricants and contaminants. They play a critical role in enhancing the lifespan and efficiency of operational systems. The price of oil seals can vary widely based on several factors, which are crucial for purchasers to understand when considering their acquisition.

Material Composition

One of the primary factors influencing oil seal prices is the material from which they are made. Common materials include rubber (such as nitrile rubber or fluorocarbon), silicone, and thermoplastic elastomers. Each material offers different levels of durability, temperature resistance, and chemical compatibility. For instance, fluorocarbon seals are typically more expensive due to their superior resilience against harsh chemicals and high temperatures. Buyers must balance their need for performance with budget constraints, leading to varying price points.

Type and Design

The design and type of oil seal also significantly affect pricing. There are various designs, such as single-lip, double-lip, and various radial lip configurations, each tailored for specific applications. Custom-designed seals that cater to unique application requirements tend to be more expensive due to the additional engineering and manufacturing processes involved. Businesses might opt for standard designs, which are generally less costly but may compromise some performance aspects.

oil seal price

Manufacturing Process

The manufacturing process used to produce oil seals also contributes to price variability. Seals manufactured using advanced techniques such as injection molding or precision machining typically carry a higher price tag due to the enhanced quality and precision. In contrast, simpler production methods might lower costs but could result in a shorter lifespan or higher failure rates. As such, buyers should consider the long-term benefits of investing in higher-quality seals versus opting for cheaper alternatives.

Market Demand and Supply

Market dynamics, including demand and supply, significantly impact oil seal prices. Factors such as economic conditions, global oil prices, and industry trends can lead to fluctuations. For instance, during periods of economic growth, the demand for machinery and vehicles rises, resulting in higher oil seal prices. Conversely, during economic downturns, decreased demand can drive prices down. Buyers should stay informed about market conditions to make timely purchasing decisions.

Conclusion

In summary, the price of oil seals is influenced by various factors, including material composition, design type, manufacturing processes, and market dynamics. For businesses and individuals looking to purchase oil seals, understanding these elements is crucial in making informed decisions. Balancing cost with performance and durability will ensure that the chosen oil seals meet the specific needs of their applications, ultimately benefiting operations in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories