Sep . 21, 2024 12:44 Back to list

oil seal manufacturer

Understanding Oil Seal Manufacturers Key Players in the Sealing Industry

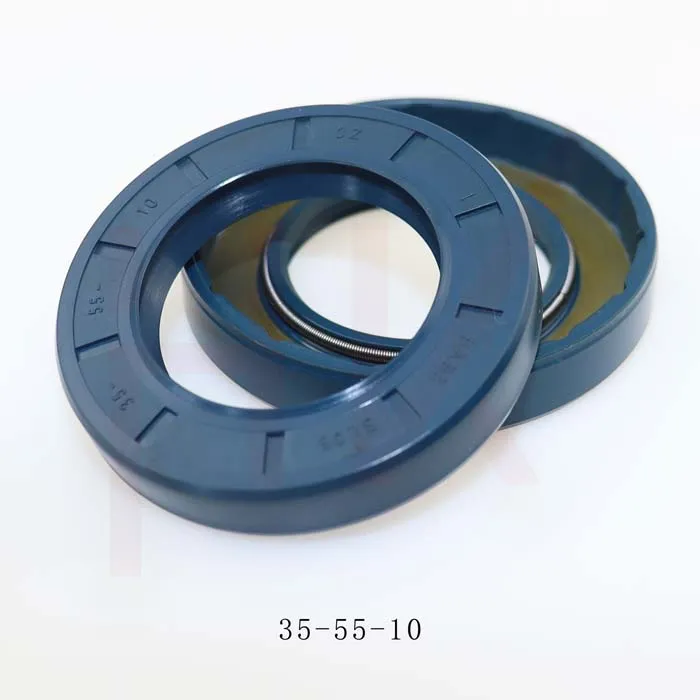

Oil seals play a crucial role in various mechanical systems, acting as barriers to prevent the leakage of oil and other fluids. This essential function not only enhances the efficiency of machinery but also prolongs the lifespan of equipment. Consequently, the demand for high-quality oil seals has led to the rise of specialized oil seal manufacturers who cater to diverse industries, including automotive, aerospace, and industrial machinery.

Oil seal manufacturers typically focus on producing seals made from materials such as rubber, silicone, and thermoplastic elastomers. These materials are chosen for their excellent resistance to temperature fluctuations, chemicals, and mechanical wear. Each manufacturer usually prides itself on the unique formulation of its sealing materials, which contributes to the overall effectiveness and durability of their products.

The process of oil seal manufacturing involves several stages, starting from design and engineering to material selection and production. Advanced technologies, such as computer-aided design (CAD) software, allow manufacturers to create precise designs tailored to specific applications. This customization is vital, as oil seals need to fit perfectly into their designated assemblies to prevent leaks and ensure optimal performance.

oil seal manufacturer

Moreover, the quality control process in oil seal manufacturing cannot be overlooked. Reputable manufacturers implement stringent testing protocols to verify the performance of their seals under various conditions. This includes tests for tensile strength, compression set, and resistance to wear and tear. Such rigorous standards ensure that the products not only meet but exceed industry expectations.

Another important aspect of oil seal manufacturers is their ability to provide technical support and consultation services. Many manufacturers work closely with their clients to understand their unique requirements and recommend the most suitable products. This collaborative approach not only facilitates the selection of appropriate seals but also fosters innovation in seal design and applications.

As industries continue to evolve and adopt more sophisticated technologies, the demand for high-performance oil seals will only increase. Manufacturers are now exploring new materials and technologies, such as biodegradable options and seals that can withstand extreme environments, in order to stay competitive in the market.

In conclusion, oil seal manufacturers are essential players in ensuring the reliability and efficiency of various mechanical systems. Their commitment to quality, innovation, and customer support makes them pivotal in the ongoing development of sealing solutions. As industries continue to face new challenges, the agility and responsiveness of oil seal manufacturers will play a significant role in driving the future of sealing technology.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories