Nov . 25, 2024 22:26 Back to list

Hydraulic Oil Seals for Enhanced Performance and Leak Prevention in Machinery

Understanding Oil Seal Hydraulics Key Components and Functions

Oil seals play a crucial role in hydraulic systems, serving as vital components that prevent the leakage of fluids and the entry of contaminants. In the world of hydraulic engineering, oil seals ensure that machinery operates efficiently and reliably. This article will delve into the various aspects of oil seal hydraulics, examining their importance, types, and applications.

What is an Oil Seal?

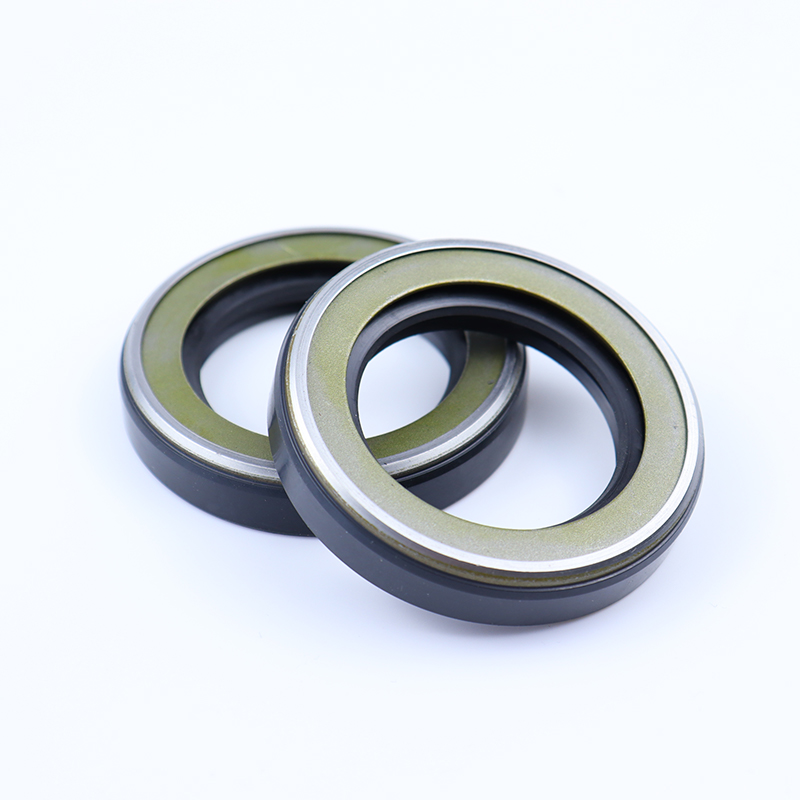

An oil seal, also known as a lip seal or rotary seal, is a device used to seal the junction between moving and stationary parts. It is often made from materials such as rubber, PTFE (Teflon), or other synthetic compounds that exhibit excellent wear resistance and flexibility. The primary function of an oil seal is to retain lubricants while preventing external contaminants like dust, dirt, and moisture from entering the system.

Importance in Hydraulic Systems

In hydraulic systems, oil seals are crucial for maintaining optimal performance. The hydraulic fluid is the lifeblood of these systems, providing the necessary pressure and lubrication to facilitate movement. Any leakage can lead to a significant drop in hydraulic pressure, resulting in system failure or reduced efficiency. Furthermore, contaminants can cause excessive wear on internal components, leading to costly repairs and downtime. Therefore, using high-quality oil seals is essential for ensuring the longevity and reliability of hydraulic machinery.

Types of Oil Seals

Oil seals come in various types, each designed to address specific applications and requirements. Here are some commonly used types

1. Single Lip Seals These seals consist of a single flexible lip that presses against a shaft, creating a barrier to retain fluid. They are widely used in smaller applications due to their simplicity and cost-effectiveness.

oil seal hydraulic

2. Double Lip Seals Featuring an additional lip, double lip seals provide enhanced protection against contaminants. The inner lip retains the lubricant while the outer lip prevents dirt from entering, making them ideal for harsh environments.

3. Spring-Loaded Seals These seals incorporate a spring to maintain constant pressure against the shaft, ensuring a tight seal even under fluctuating temperatures or pressures. They are particularly useful in dynamic applications where the shaft experiences considerable movement.

4. V-Rings V-rings are a type of oil seal that fits onto a shaft and creates a seal between the shaft and housing. They are often used in combination with other seals to provide additional protection.

Applications in Industry

Oil seals are widely used across various industries due to their versatility and effectiveness. In automotive applications, oil seals are often found in engines, transmissions, and differentials where they help retain lubrication while preventing leaks. In industrial machinery, oil seals are used in hydraulic cylinders, pumps, and gearboxes, ensuring smooth operation and preventing fluid loss.

Moreover, the oil and gas sector heavily relies on oil seals to protect equipment operating in extreme conditions. Offshore drilling rigs, for example, require robust sealing solutions to combat the harsh environmental conditions and ensure operational efficiency.

Conclusion

Oil seals are indispensable components in hydraulic systems, providing essential sealing solutions to prevent fluid leakage and protect against contamination. Their variety of designs allows for specific applications across multiple industries, reinforcing the idea that effective hydraulic performance depends significantly on the quality of oil seals used. As technology continues to evolve, advancements in materials and designs will further enhance the reliability and efficiency of oil seals in hydraulic systems, paving the way for future innovations in the field.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories