Oct . 19, 2024 13:34 Back to list

oil seal hub

Understanding Oil Seal Hubs A Comprehensive Guide

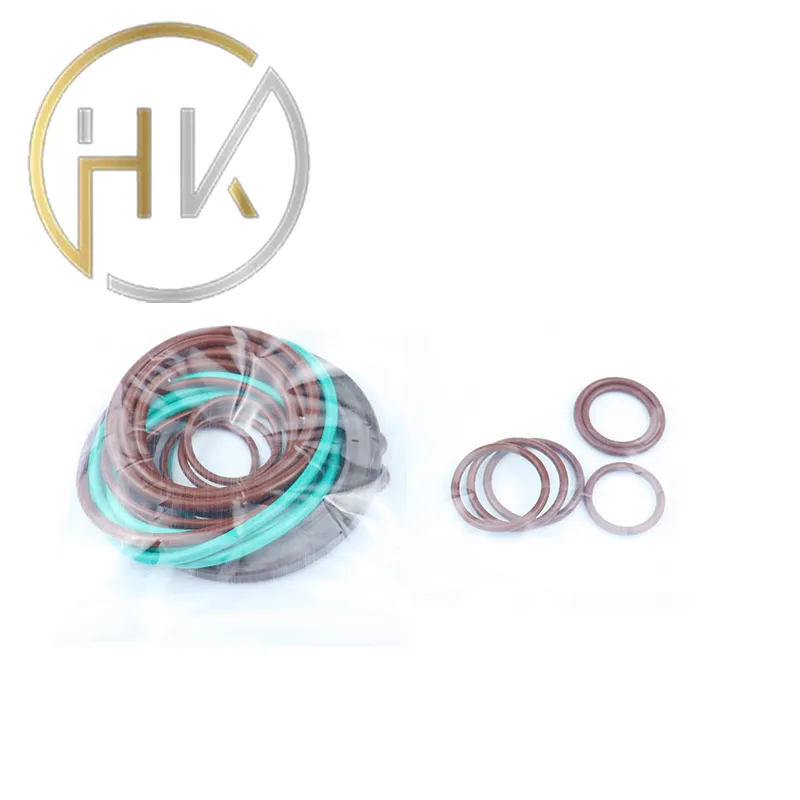

Oil seals, often referred to as lip seals or fluid seals, play a pivotal role in ensuring the smooth operation of various machinery by retaining lubricants and preventing the ingress of contaminants. Among the various components of an oil seal, the hub is critical in providing structural support and ensuring proper sealing performance. This article delves into the intricacies of oil seal hubs, covering their design, function, materials, and applications.

What is an Oil Seal Hub?

The oil seal hub is the central component of an oil seal assembly, where the sealing lip is mounted. The hub is typically circular and is designed to fit snugly onto a shaft or within a housing, allowing the oil seal to perform its function effectively. The primary purpose of the hub is to provide a stable base for the seal, ensuring that it remains in position under varying operational conditions.

Design and Functionality

An oil seal hub features several design characteristics that enhance its functionality

1. Shape and Size The hub is designed to match the diameter of the shaft or housing it seals. It is important that the fit is precise to prevent leaks. Manufacturers often provide various sizes to accommodate different applications.

2. Material Hubs are commonly manufactured from materials such as metal, plastic, or rubber, depending on the specific requirements of the application. Metal hubs are particularly advantageous in high-temperature environments, while plastic hubs are often used in lighter applications.

3. Surface Finish The surface of the hub must be smooth to allow for effective sealing. Any imperfections can lead to premature wear of the sealing lip and compromise its effectiveness.

4. Design Features Certain oil seal hubs might include additional features such as grooves or flanges that help in anchoring the seal in place and enhancing its sealing capabilities.

Importance of Oil Seal Hubs

Oil seal hubs are vital to the performance of machinery due to several factors

oil seal hub

- Leak Prevention One of the primary roles of an oil seal hub is to prevent lubricant leakage. This is critical for maintaining the efficiency and longevity of machinery, especially in high-speed or high-load applications.

- Contaminant Exclusion Besides retaining lubricants, oil seals also prevent dirt, dust, and other contaminants from entering the machinery. This is especially essential in environments where exposure to airborne particles is high.

- Operational Efficiency By ensuring that lubricants remain where they are needed, oil seal hubs contribute to reduced friction and wear within machinery, ultimately enhancing performance and reducing maintenance costs.

Applications of Oil Seal Hubs

Oil seal hubs are widely used across various industries, including

- Automotive In vehicles, oil seals are utilized in engines, transmissions, and differentials to prevent oil leaks and ensure smooth operation of moving parts.

- Industrial Machinery Various types of industrial machines, including pumps, compressors, and conveyors, rely on oil seals to maintain their efficiency and operational integrity.

- Aerospace The aerospace industry uses oil seals in engines and hydraulic systems, where reliability and performance are critical.

- Home Appliances Oil seals can also be found in home appliances, such as washing machines and refrigerators, where they help in preventing leaks and maintaining system integrity.

Conclusion

In summary, oil seal hubs are essential components that provide the necessary support for effective sealing operations in various mechanical systems. Their design, materials, and construction play a significant role in ensuring that lubricants are retained while preventing the ingress of contaminants. As technology continues to advance, the development of more efficient and durable oil seal hubs will further enhance the performance and reliability of machinery across multiple applications. Understanding these components is crucial for engineers, technicians, and manufacturers looking to optimize their machinery's functionality and longevity.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories