Dec . 06, 2024 15:45 Back to list

oil seal for rotating shaft

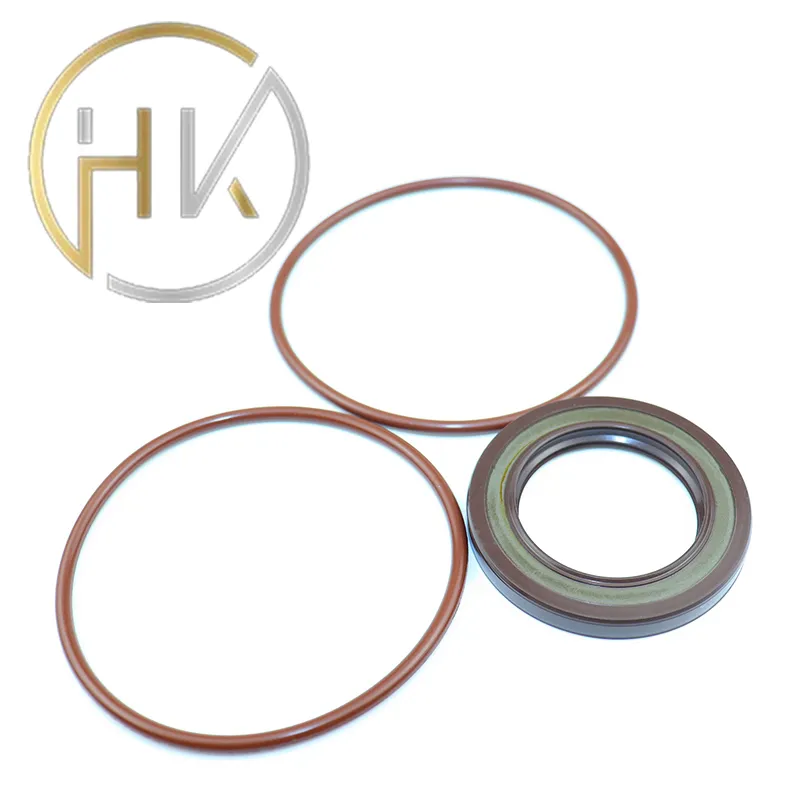

Understanding Oil Seals for Rotating Shafts

Oil seals, also known as rotary shaft seals, play a crucial role in various mechanical systems, where they perform the vital function of preventing the leakage of lubricants and the ingress of contaminants. These seals are typically made from elastomeric materials, which provide a resilient seal around rotating shafts, ensuring optimal performance and longevity of machinery. This article explores the importance, types, applications, and maintenance of oil seals for rotating shafts.

Importance of Oil Seals

The primary function of oil seals is to keep lubricants within a machine while preventing external contaminants from entering. In rotating machinery, this is critical because the lubricants reduce friction, minimizing wear and heat generation. Without effective sealing, oil leaks could lead to insufficient lubrication, resulting in increased wear, overheating, and eventual failure of the machinery.

Moreover, oil seals protect machinery from contaminants like dust, dirt, and water, which can cause significant damage to internal components. By maintaining a clean operational environment within the machinery, oil seals enhance the reliability and efficiency of the equipment, ultimately extending its service life.

Types of Oil Seals

There are several types of oil seals designed for various applications. The most common types include

1. Single-Lip Seals These are the simplest form of oil seals and consist of a single lip that contacts the rotating shaft, forming the seal. They are suitable for moderate speeds and low-pressure applications.

2. Double-Lip Seals Featuring two lips, these seals provide enhanced protection against contaminants and are often used in applications where the environment is particularly harsh. The additional lip helps keep lubricant inside while providing a secondary barrier against ingress.

3. Spring-Loaded Seals These seals incorporate a spring that maintains pressure on the sealing lip against the shaft. This design helps improve the seal's performance across a range of operating conditions, making them suitable for high-speed and high-pressure applications.

oil seal for rotating shaft

4. Metal Clad Seals These seals feature a metal outer casing, providing additional strength and durability, which is essential in heavy-duty applications.

5. Profile Seals These seals are designed with unique profiles to suit specific applications, providing enhanced sealing performance.

Applications

Oil seals are widely used across various industries, including automotive, aerospace, manufacturing, and heavy machinery. In the automotive industry, oil seals are critical in engines, transmissions, and differentials, where they ensure that lubricants remain contained while protecting internal components from contamination.

In the aerospace sector, oil seals maintain the integrity of hydraulic systems, ensuring that fluids remain contained under high pressure and temperature. Similarly, in manufacturing, oil seals are essential for machines that involve rotating shafts, such as pumps, motors, and gearboxes, maintaining efficiency and preventing costly downtime due to leaks or failures.

Maintenance and Replacement

Proper maintenance of oil seals is essential to ensure their longevity and effectiveness. Regular inspections can help identify wear signs, such as cracks or hardened rubber, which may indicate that replacement is necessary. It’s also crucial to monitor the condition of the lubricant, as degraded fluid can compromise the performance of the seal.

When replacing oil seals, it is vital to use seals that meet the manufacturer's specifications. Proper installation is equally important, as incorrect installation can lead to premature failure or leakage.

Conclusion

In summary, oil seals for rotating shafts are integral components that significantly impact the performance and reliability of various mechanical systems. By effectively containing lubricants and preventing contamination, they protect machinery from damage and ensure optimal operational efficiency. Understanding the types and applications of oil seals, along with proper maintenance practices, can help industries maximize their equipment's lifespan and performance, leading to increased productivity and reduced operational costs. As machinery continues to evolve, the importance of high-quality oil seals will remain paramount in maintaining the integrity of rotating systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories