Dec . 05, 2024 11:28 Back to list

Understanding Oil Seals for Effective Rotating Shaft Applications and Maintenance

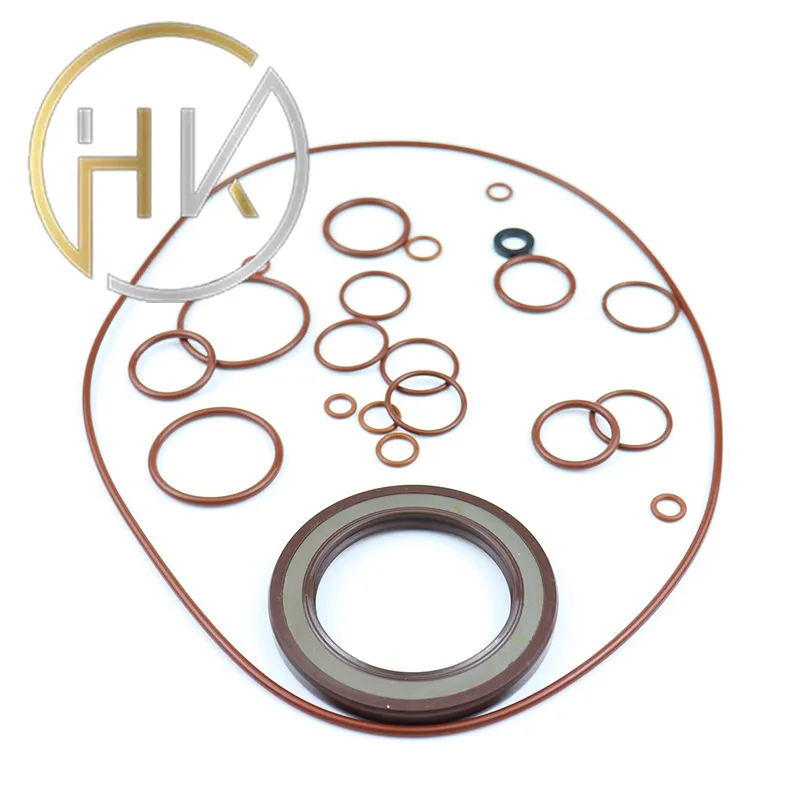

Oil Seals for Rotating Shafts An Essential Component for Mechanical Integrity

Oil seals, also known as rotary seals or shaft seals, play a crucial role in ensuring the efficiency and longevity of machinery that involves rotating shafts. These components are designed to prevent lubricant leakage and keep contaminants out, thereby protecting both the internal surfaces of machinery and the quality of the lubricants used. In any mechanical system where lubrication is necessary, the use of oil seals is vital.

The Function of Oil Seals

Oil seals serve multiple purposes in mechanical applications. Their primary function is to create a barrier that retains lubricants while prohibiting the ingress of dirt, dust, moisture, and other contaminants that can cause wear and damage to vital components. By maintaining the appropriate lubricant levels, oil seals ensure that moving parts can operate smoothly with minimal friction, ultimately enhancing the performance and lifespan of machinery.

Additionally, oil seals help maintain pressure within the system, which can be particularly important in hydraulic applications. They are designed to withstand the specific pressures exerted by the lubricants and the environmental conditions in which they operate. This allows for the efficient transfer of power within systems like engines, gearboxes, and pumps.

Types of Oil Seals

Oil seals come in various designs and materials, each tailored to specific applications. The most common types of oil seals include

1. Rubber Oil Seals These are typically made from materials such as nitrile rubber (NBR), fluorocarbon rubber (FKM), or silicone. They are flexible and resilient, making them suitable for a wide range of temperatures and pressures.

2. Metal-Cased Oil Seals These seals have a metal outer casing that provides additional strength and durability. They are often used in more demanding environments where additional pressure resistance is necessary.

3. Lip Seals The sealing surface, or lip, is designed to fit snugly against the shaft to prevent leakage. The geometry of the lip can vary, with some seals featuring multiple lips for enhanced sealing capabilities.

oil seal for rotating shaft

Factors to Consider When Choosing Oil Seals

Selecting the right oil seal for a particular application involves considering several factors

- Operating Environment The temperature, pressure, and exposure to chemicals will greatly influence the choice of material for the oil seal.

- Shaft Diameter and Speed The dimensions of the shaft and its rotational speed can impact the effectiveness of the seal. It's essential to select a seal that can accommodate these parameters without compromising performance.

- Application Type Different applications may require specific sealing capabilities. For instance, automotive applications may have different requirements than industrial equipment.

- Expected Lifespan The durability of oil seals is crucial for minimizing maintenance and operational costs. Choosing high-quality seals may incur a higher initial expense but can lead to significant savings in the long run.

Conclusion

Oil seals for rotating shafts are indispensable components that ensure the efficiency, safety, and longevity of mechanical systems. By preventing leaks and protecting against contaminants, they play a vital role in the smooth operation of a wide variety of machinery, from automobiles to industrial equipment. In an era where downtime can be costly, investing in quality oil seals is paramount for any business that relies on rotating machinery. Proper selection and maintenance of these seals will not only contribute to optimal performance but will also enhance the overall reliability of the equipment in use.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories