Dec . 19, 2024 18:31 Back to list

oil seal for pump

Understanding Oil Seals for Pumps Importance and Functionality

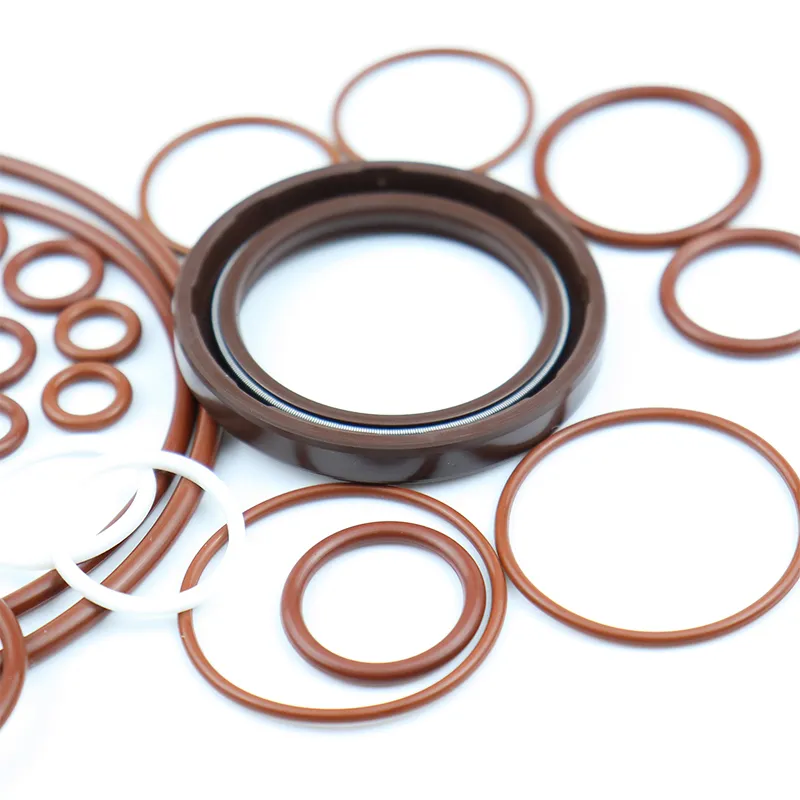

Oil seals, also known as grease seals or shaft seals, are critical components used in various machinery applications, particularly in pumps. These seals are designed to retain lubrication within the assembly while preventing the ingress of contaminants, such as dirt, dust, and moisture. Understanding the function, construction, and maintenance of oil seals is essential for optimizing the performance and longevity of pumps.

The Importance of Oil Seals

Oil seals serve several crucial functions in pump operation. Primarily, they ensure a proper sealing surface between rotating and stationary components, allowing for effective containment of lubricants. This containment is vital in reducing friction between moving parts, which ultimately minimizes wear and prolongs the life of both the pump and its components.

Additionally, oil seals play a pivotal role in preventing the leakage of fluids, which can result in operational inefficiencies, increased maintenance costs, and environmental concerns. Fluid leaks can lead to potential hazards, especially in industrial settings where pumping hazardous materials is common. Therefore, having robust and reliable oil seals is paramount in maintaining operational integrity and safety.

Construction and Material Selection

Oil seals are generally made of flexible rubber or synthetic materials that provide a reliable barrier against various types of fluids. The most common materials include nitrile rubber (NBR), fluorocarbon (FKM), and polyurethane. Each material type offers specific advantages depending on the application. For example, NBR is widely used for its excellent oil and gas resistance, while FKM is preferred in high-temperature applications due to its superior thermal stability.

oil seal for pump

The construction of an oil seal typically includes a sealing lip that is designed to hug the shaft tightly. This lip creates a dynamic seal that adjusts to the slight movements of the shaft during operation. The design may also incorporate a spring that helps the lip maintain contact with the shaft, ensuring an effective seal even under varying operational conditions.

Maintenance of Oil Seals

Proper maintenance of oil seals is critical for ensuring their longevity and effectiveness. Regular inspection for any signs of wear, damage, or leaks is crucial. If an oil seal is compromised, it should be replaced promptly to avoid further damage to the pump's internal components. It's also essential to ensure that the shaft surfaces are smooth and free of imperfections, as rough surfaces can lead to premature seal wear.

Additionally, selecting the right oil seal for the specific pump application is paramount. Consideration of factors such as the type of fluid being pumped, operating temperatures, and pressure levels can help in choosing the most suitable oil seal material and design.

Conclusion

Oil seals are indispensable components in the functioning of pumps, ensuring efficiency and reliability in operations. Their primary role in retaining lubricants and preventing leaks emphasizes the need for quality materials and proper maintenance practices. By investing in high-quality oil seals and adhering to regular inspection and maintenance protocols, businesses can significantly enhance the performance and lifespan of their pumping systems, leading to improved productivity and reduced operational costs. Whether for industrial, agricultural, or commercial applications, understanding and managing oil seals effectively is key to successful pump operation.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories