Nov . 22, 2024 05:26 Back to list

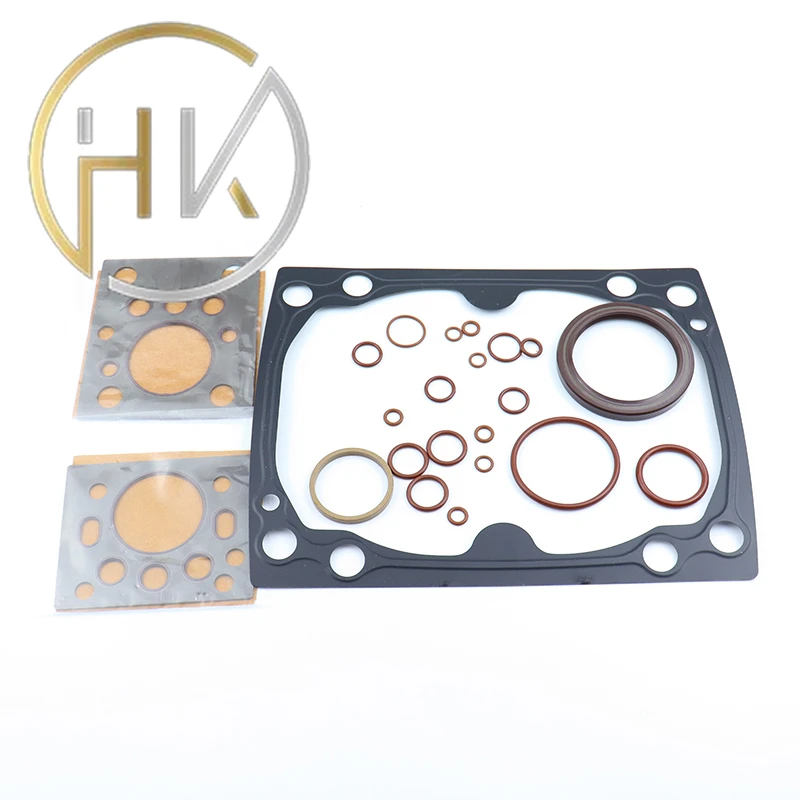

oil seal for pump

Understanding Oil Seals for Pumps Importance, Types, and Applications

Oil seals, also known as grease seals, play a critical role in the operation and longevity of various types of pumps. These essential components are designed to retain lubrication while keeping contaminants such as dirt, dust, and moisture out of the pump system. Understanding the significance of oil seals in pumps, along with their types and applications, is crucial for anyone involved in maintenance and repair of pumping equipment.

Importance of Oil Seals

Oil seals serve two main purposes sealing and protection. They prevent the loss of lubricants, which are necessary to minimize friction between moving parts. By maintaining the oil within the pump, these seals ensure the pump operates smoothly, efficiently, and with minimal wear. Furthermore, oil seals protect the internal components of the pump from external contaminants that could lead to mechanical failure. Over time, a malfunctioning oil seal can result in severe damage, leading to costly repairs or replacement of the entire pump.

Types of Oil Seals

Several types of oil seals are commonly used in pumps, each designed for specific applications. The most frequently utilized types include

1. Rotary Oil Seals These are used for rotating shafts and are specifically designed to withstand high rotational speeds while preventing leakage. Rotary oil seals are often made from materials such as rubber or polyurethane to provide effective sealing performance.

2. Mechanical Seals Unlike traditional oil seals, mechanical seals are used in applications where high pressures and temperatures are present. These seals feature two mating surfaces that prevent leakage through a combination of sealing and hydraulic pressure. Mechanical seals are often found in centrifugal pumps and are preferred in industries such as oil and gas or chemical processing.

3. Lip Seals Lip seals have a flexible lip that makes contact with the shaft, providing an effective seal against both oil leakage and external contaminants. They are widely used in various pumps due to their efficiency and adaptability.

4. Envelope Seals These seals consist of a flexible inner seal and an outer sleeve that protects it from external wear. Envelope seals are useful in harsh environments, offering robust protection against contamination.

Material Considerations

oil seal for pump

The material used for oil seals significantly affects their performance and durability

. Common materials include- Nitrile Rubber (NBR) Known for its excellent resistance to oil, fuel, and other petroleum products, NBR is often used for oil seals operating in moderately high temperatures.

- Fluoroelastomer (FKM) With exceptional temperature and chemical resistance, FKM is ideal for seals that face harsh chemicals and extreme temperatures.

- Polyurethane This material offers a good balance of abrasion resistance, flexibility, and adaptability to various conditions, making it suitable for a wide range of oil sealing applications.

Applications of Oil Seals in Pumps

Oil seals can be found in numerous types of pumps used across various industries. Some common applications include

- Centrifugal Pumps These pumps rely on mechanical or rotary oil seals to ensure reliable performance and prevent lubricant loss during operation.

- Positive Displacement Pumps Oil seals play a critical role in maintaining pressure and preventing leaks in positive displacement pumps used in hydraulic applications.

- Industrial Pumps In heavy-duty industrial environments, oil seals protect critical components while ensuring the safe transport of fluids containing abrasive or corrosive materials.

Conclusion

In conclusion, oil seals are vital components in the world of pump technology, serving as the first line of defense against lubricant loss and external contaminants. By ensuring the integrity and longevity of pumping systems, these seals contribute significantly to operational efficiency and reliability. Understanding the types of oil seals available, their materials, and their applications can help technicians and engineers make informed decisions when selecting the right seal for their pumping needs. Proper selection, installation, and maintenance of oil seals will undoubtedly enhance the performance of pumps and extend their service life, ultimately leading to improved productivity and reduced operational costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories