Oct . 01, 2024 08:10 Back to list

Alternative Seals for Pump Applications Enhancing Performance and Reliability

Understanding Oil Seals for Pumps

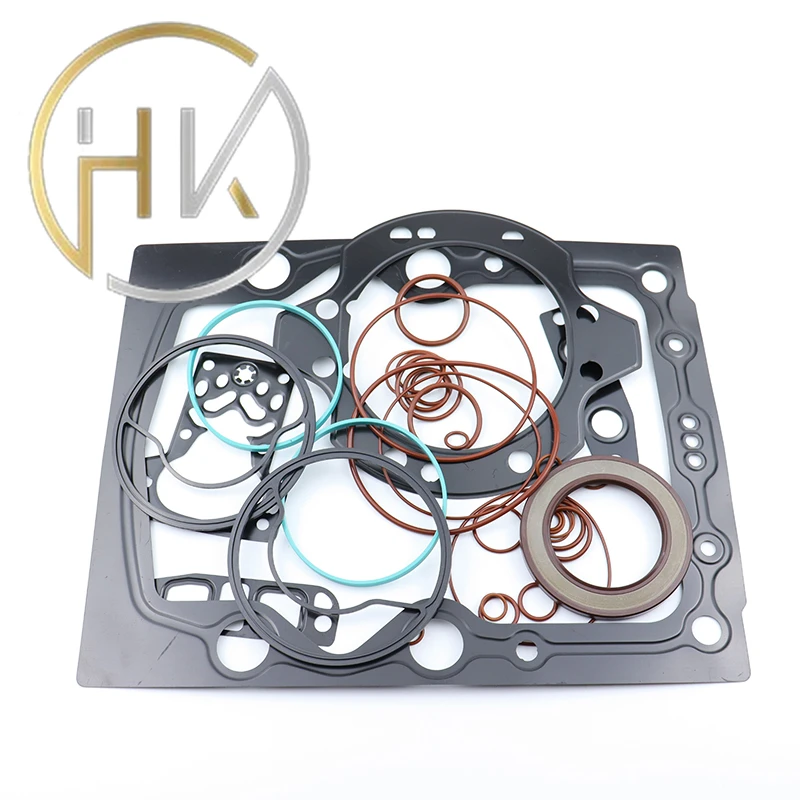

Oil seals, also known as radial shaft seals, are critical components in the operation of various types of pumps. They serve an essential function in preventing leakage of lubricants, oils, and fluids from the pump assembly. This article outlines the importance, types, applications, and maintenance of oil seals used in pump systems.

Importance of Oil Seals

Oil seals play a crucial role in maintaining the efficiency and longevity of pumps. Their primary function is to seal the space between the rotating shaft and the stationary housing, effectively preventing the escape of lubricants which is vital for the smooth operation of the pump. When pumps lose lubrication, it can lead to increased friction, overheating, and eventually, pump failure. Consequently, using high-quality oil seals can significantly enhance pump performance and reduce the likelihood of costly repairs and downtime.

Types of Oil Seals

Oil seals come in various types, each designed to suit specific applications and environments. Some of the most common types include

1. Single Lip Seals This type consists of a single sealing lip that makes contact with the shaft. They are ideal for low-pressure applications and are often found in smaller pumps.

2. Double Lip Seals Featuring two sealing lips, these seals provide an extra layer of protection against leakage. They are more effective in high-pressure applications and are typically used in heavy-duty pumps.

3. Spring-Loaded Seals These seals use a spring mechanism to maintain pressure against the shaft, ensuring a tight seal even under varying operational conditions. They are ideal for dynamic applications where the shaft rotates at high speeds.

4. PTFE Seals Made from polytetrafluoroethylene, these seals are highly resistant to chemicals and extreme temperatures. This makes them suitable for pumps handling aggressive fluids or operating in harsh environments.

Applications of Oil Seals in Pumps

Oil seals find applications in various types of pumps, including

- Centrifugal Pumps These pumps, often used in water supply and chemical processing, rely on oil seals to prevent leakage and maintain hydraulic pressure

.oil seal for pump

- Positive Displacement Pumps In applications requiring high precision, such as in the food and beverage industry, oil seals help ensure product integrity by preventing cross-contamination.

- Hydraulic Pumps In hydraulic systems, oil seals are vital to keep hydraulic fluids contained, ensuring the system operates efficiently under pressure.

- Submersible Pumps Used for dewatering and sewage applications, these pumps require robust oil seals to withstand submerged conditions.

Maintenance of Oil Seals

Maintaining oil seals in pumps is essential for their longevity and optimal performance. Here are several best practices

1. Regular Inspections Frequent checks can help identify wear and tear or potential leaks before they escalate into significant issues.

2. Proper Installation Ensuring that oil seals are installed correctly is paramount. An improper fit can lead to premature failure, so following manufacturer guidelines during installation is crucial.

3. Monitoring Fluid Levels Keeping an eye on fluid levels can help detect leaks early. If levels drop significantly, it might indicate that the oil seal has failed.

4. Temperature Control Excessive heat can degrade oil seals. Ensuring that the pump operates within the recommended temperature range can extend the seal's lifespan.

5. Choosing the Right Material Selecting oil seals that are compatible with the specific fluids and operational conditions of the pump can prevent chemical degradation and breakdown.

Conclusion

Oil seals are integral to pump functionality, providing essential sealing and protection against fluid leakage. Understanding the types, applications, and maintenance of oil seals is crucial for anyone involved in the operation and upkeep of pump systems. By selecting the right oil seals and maintaining them properly, you can enhance the performance and longevity of pumps, ensuring they operate efficiently in various industrial applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories