Nov . 29, 2024 21:03 Back to list

Leading Manufacturers of Oil Seals for Enhanced Performance and Durability in Various Industries

Understanding Oil Seal Companies A Key Component in Machinery Efficiency

Oil seals are critical components in various machinery and automotive applications, designed to prevent the leakage of oils and other fluids while keeping contaminants out. The companies that specialize in manufacturing oil seals play a crucial role in maintaining the efficiency and longevity of machinery across countless industries. In this article, we will explore the significance of oil seal companies, the types of seals they produce, their applications, and the factors driving innovation in this sector.

The Importance of Oil Seals

Oil seals are essential in ensuring the smooth operation of machinery by reducing friction and wear between moving parts. They help maintain the correct lubrication levels by preventing the escape of lubricants, which can lead to overheating and premature component failure. Additionally, oil seals act as barriers against dirt, dust, and moisture, which can compromise the internal environment of machinery, causing operational inefficiencies and costly repairs.

Types of Oil Seals

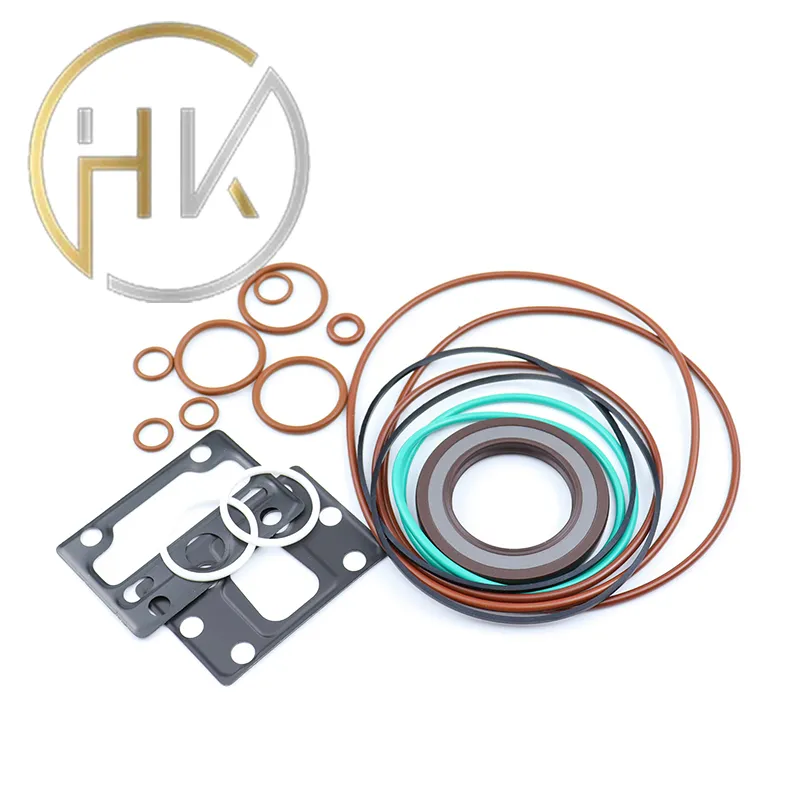

Oil seal companies manufacture a wide variety of seals to cater to different applications. The most common types include

1. Rotary Seals These are designed for rotating shafts and are widely used in automotive engines, gearboxes, and pumps. Rotary seals need to withstand high speeds and varying temperatures while maintaining effective sealing.

2. Static Seals These seals are used in non-moving applications where two components meet, preventing leakage between them. Static seals are common in pipe flanges and hydraulic cylinders.

3. Mechanical Seals Often found in pumps and mixers, mechanical seals provide a reliable sealing solution for applications that require dynamic sealing while under pressure.

Each of these seal types is engineered for specific applications, considering factors such as pressure, temperature, and medium compatibility. Custom oil seal manufacturing has also become a significant offering as companies strive to meet unique client specifications.

oil seal companies

Applications Across Industries

The versatility of oil seals allows them to be utilized in various industries. In the automotive sector, they are indispensable for preventing oil leaks in engines and transmissions. In industrial machinery, oil seals help maintain lubrication in gear systems, hydraulic presses, and conveyor systems, thereby enhancing productivity.

Moreover, oil seals are critical in manufacturing equipment, including pumps, motor vehicles, aerospace components, and agricultural machinery. The growing demand for automation and machinery upgrades across these sectors has led to an increased requirement for high-quality oil seals.

Factors Driving Innovation

Oil seal companies are continuously innovating to meet modern machinery's evolving requirements. Key drivers of innovation include

1. Material Advancements The development of new materials, such as fluoropolymers and enhanced rubber compounds, has improved the performance and durability of oil seals. These materials can withstand extreme temperatures and aggressive chemicals, expanding the application range.

2. Sustainability Initiatives As industries pivot towards more sustainable practices, oil seal manufacturers are also adopting eco-friendly materials and production processes. This shift not only reduces environmental impact but also meets the rising consumer demand for greener products.

3. Technological Integration Advancements in manufacturing technologies, such as precision molding and 3D printing, have enabled companies to produce seals with tighter tolerances and better quality assurance. Moreover, integrating smart sensors into oil seals can provide real-time diagnostics, alerting operators to potential failures before they escalate.

4. Global Market Trends As the global machinery market continues to grow, particularly in emerging economies, oil seal companies are expanding their operations to cater to diverse markets. This globalization fosters competition, leading to enhanced product offerings and better service standards.

Conclusion

Oil seal companies play a pivotal role in the maintenance and efficiency of machinery across various industries. By providing reliable sealing solutions, they protect vital components from fluid leaks and contaminants, ensuring operational longevity and efficiency. As technology continues to advance, these companies will remain instrumental in driving innovation and meeting the changing demands of the market, shaping the future of manufacturing and machinery management.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories