Nov . 24, 2024 16:20 Back to list

oil pump seal

Understanding Oil Pump Seals Importance, Types, and Maintenance

Oil pumps are vital components in many mechanical systems, particularly in automotive engines and industrial machinery. They are designed to circulate oil to lubricate moving parts, preventing wear and ensuring smooth operation. However, the efficiency of an oil pump largely depends on the quality of its seals. In this article, we will explore the significance of oil pump seals, the different types available, and some essential maintenance tips.

The Importance of Oil Pump Seals

Oil pump seals play a crucial role in maintaining the integrity and performance of an oil pumping system. They are responsible for containing the oil within the pump, preventing leaks that can lead to reduced lubrication, increased friction, and potential damage to the engine or machinery. A small oil leak may seem inconsequential, but it can result in significant operational failures and costly repairs if left unchecked.

Moreover, oil pump seals help to maintain the necessary pressure within the pump. This pressure is vital for ensuring proper oil flow to the engine or system it serves. If the seal fails, it can lead to a drop in pressure, compromising the lubrication process and putting excessive strain on engine components. Therefore, effective seals are essential for reliable and long-lasting performance.

Types of Oil Pump Seals

There are several types of seals used in oil pumps, each suited for different applications and operating conditions

. The most common types include1. O-Ring Seals These are circular seals made from various materials such as rubber or elastomers. They are widely used due to their simplicity and effectiveness in maintaining a seal under high pressure and temperature variations.

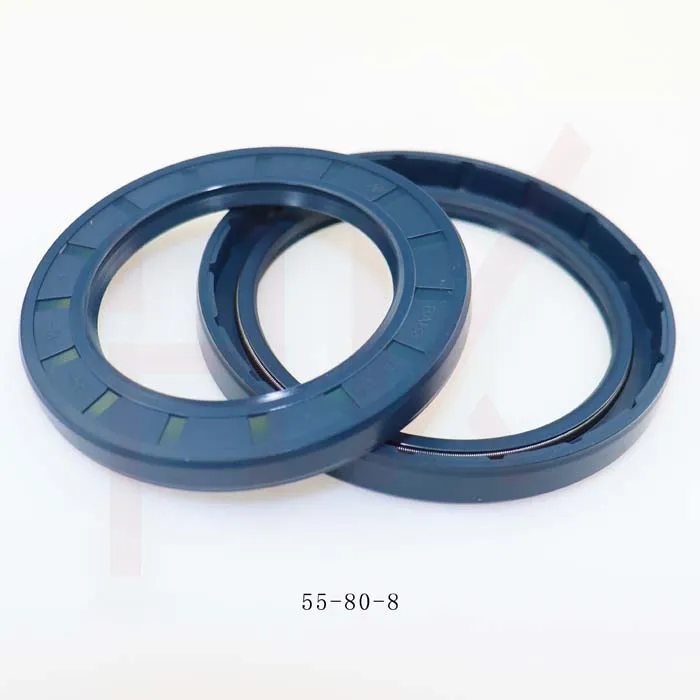

2. Lip Seals Lip seals consist of a flexible lip that makes contact with the shaft or housing. They provide excellent sealing properties and can tolerate a range of operating conditions. Lip seals are commonly used in rotating equipment, making them ideal for oil pumps.

3. Mechanical Seals These are more complex than O-rings and lip seals, comprising two or more components that create a seal between rotating and stationary parts. Mechanical seals are known for their reliability in high-pressure and high-temperature applications, making them suitable for heavy-duty oil pumps.

oil pump seal

4. Gasket Seals Gaskets can also be used in oil pumps, providing a static seal between two surfaces. They are typically made from materials like cork, rubber, or silicone and are used where parts of the pump are bolted together.

Maintenance Tips for Oil Pump Seals

To ensure optimal performance of oil pump seals, regular maintenance is essential. Here are some tips to help maintain the integrity of oil pump seals

1. Regular Inspections Periodically inspect your oil pump for signs of leakage around the seals. Early detection of leaks can prevent larger issues and costly repairs in the future.

2. Use the Right Oil The type of oil used can impact the lifespan of seals. Always use the manufacturer-recommended oil to ensure compatibility with the seal material.

3. Check for Wear and Tear Over time, seals can become worn due to heat, pressure, and exposure to various chemicals. Replace any seals that show signs of deterioration to prevent leaks.

4. Monitor Operating Conditions Extreme temperatures and pressures can put additional stress on oil pump seals. Ensure that your equipment operates within the recommended parameters to extend the life of the seals.

5. Installation Practices When replacing oil pump seals, follow proper installation procedures. Incorrect installation can lead to premature failure, so it's essential to ensure that seals are properly seated and aligned.

Conclusion

Oil pump seals are more than mere components; they are critical to the functioning of machinery and engines that rely on oil for lubrication. By understanding their importance, knowing the different types, and committing to regular maintenance, users can significantly enhance the performance and longevity of their oil pumps. Protecting these seals is essential for preventing leaks, maintaining pressure, and ensuring the reliable operation of mechanical systems. Regular checks and proper care are key to keeping oil pumps running smoothly and effectively, ultimately saving time and money in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories