Oct . 16, 2024 20:00 Back to list

oil hub seal

The Importance of Oil Hub Seals in Modern Industry

In the world of industrial operations, oil hubs serve as crucial components in various machinery and applications, ranging from automotive to heavy machinery. At the heart of these oil hubs lies the oil hub seal, a small but vital element that ensures efficiency, safety, and longevity of equipment.

Understanding Oil Hub Seals

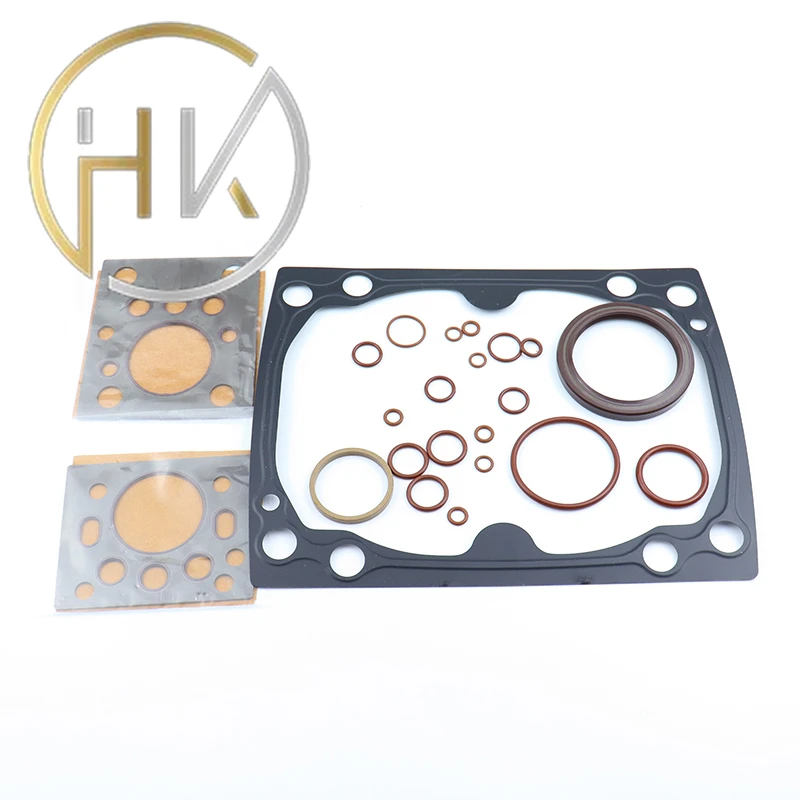

An oil hub seal is a mechanical component designed to contain and manage the flow of oil within machines. Its primary function is to prevent leakage, which is critical in maintaining oil levels essential for lubrication, cooling, and proper functioning of moving parts. Oil hub seals are typically made from durable materials such as rubber or synthetic elastomers, designed to withstand high pressure, temperature fluctuations, and exposure to various chemical agents.

Functionality and Design

The design of an oil hub seal involves meticulous engineering to achieve an effective seal while allowing for necessary movement within the machinery. These seals operate by creating a barrier that keeps oil confined within the hub, preventing it from escaping into the environment. This containment is vital not only for maintaining lubrication but also for preventing environmental contamination and ensuring compliance with regulatory standards.

Oil hub seals come in a variety of shapes and sizes depending on their application. For example, automotive oil hub seals are designed differently from those in industrial machinery due to differences in operational demands. Furthermore, the choice of material significantly affects the seal's performance. Advanced materials offer enhanced resistance to wear and tear, temperature, and chemical exposure, prolonging the lifespan of the seal and the machinery.

Importance in Machinery Efficiency

The efficiency of machinery is heavily reliant on the presence of effective oil hub seals

. When seals fail, it can lead to oil leaks, which not only compromise lubrication but also result in overheating and premature wear of components. This can lead to costly repairs and downtime, significantly affecting productivity.oil hub seal

Regular maintenance and inspection of oil hub seals are essential practices in industrial settings. Companies must be vigilant about monitoring seal integrity, as even minor leaks can escalate into major issues. Proactive maintenance can save organizations from significant financial losses due to equipment failure.

Environmental Considerations

In today's environmentally conscious world, the role of oil hub seals extends beyond machinery efficiency. Oil leaks due to failed seals can lead to environmental pollution, affecting soil and water quality. Thus, using high-quality, reliable oil hub seals is not just about machinery performance; it’s also about upholding corporate responsibility and environmental stewardship.

Adopting eco-friendly lubricants and ensuring the integrity of oil hub seals can significantly reduce the risk of environmental contamination. Companies that prioritize the use of reliable seals benefit from both enhanced machinery performance and a positive public image, showcasing their commitment to sustainable practices.

Innovations in Oil Hub Seal Technology

As technology advances, so too does the design and functionality of oil hub seals. Innovations are leading to the development of smart seals equipped with sensors that can monitor their integrity and performance in real time. These smart seals can alert operators to potential failures before they occur, facilitating timely interventions and maintenance.

The integration of such technology not only improves the reliability of seals but also enhances overall machine performance, paving the way for smarter and more efficient industrial practices.

Conclusion

Oil hub seals are an essential aspect of modern machinery, playing a pivotal role in ensuring efficient operation, safety, and environmental protection. Recognizing their importance can lead to better maintenance practices and innovations in seal technology, ultimately contributing to more sustainable and productive industrial operations. As industries continue to evolve, so will the role of oil hub seals, making them an indispensable cog in the machinery of progress.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories