Oct . 11, 2024 04:37 Back to list

metric wiper seals

Understanding Metric Wiper Seals Key Components for Hydraulic and Pneumatic Systems

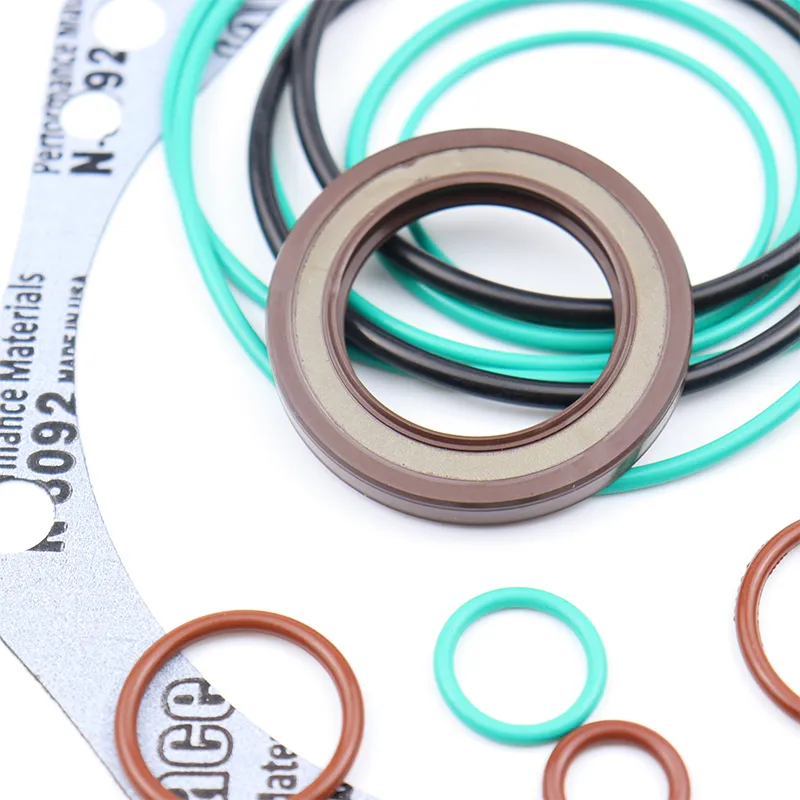

In the world of engineering and manufacturing, the reliability and efficiency of machinery largely depend on the components used in their construction. One critical component that plays a significant role in the smooth operation of hydraulic and pneumatic systems is the wiper seal. Particularly, metric wiper seals are designed for international applications where precision and standardization are paramount. This article explores the importance of metric wiper seals, their design, functionality, and application across various industries.

What are Wiper Seals?

Wiper seals, also known as scraper seals, are designed to prevent dirt, dust, and other contaminants from entering critical moving parts of machinery, such as hydraulic cylinders and pneumatic actuators. They are typically located at the outer edge of a cylinder or rod, acting as the first line of defense against external pollutants. The effectiveness of wiper seals is vital for prolonging the lifespan of hydraulic and pneumatic components, thereby enhancing the overall efficiency of the system.

The Significance of Metric Standards

Metric wiper seals conform to international standards, making them essential for manufacturers and engineers who operate on a global scale. The metric system provides a universal language for measurements, facilitating easier interchangeability and installation in various systems. This is particularly important in industries such as automotive, aerospace, and manufacturing, where components are often sourced from different countries.

Design Considerations

The design of metric wiper seals typically includes several factors

1. Material Selection Wiper seals are made from various materials, including elastomers like nitrile, polyurethane, and fluorocarbon. The choice of material depends on the application, temperature range, and potential exposure to chemicals or harsh environments.

2. Profile Shape The profile of a wiper seal is crucial for its performance. Common shapes include lip seals, U-cup seals, and V-rings. The design must balance effective wiping action with minimal drag on the moving surfaces, as excessive drag can lead to increased wear and energy loss.

3. Size and Tolerance Metric wiper seals come in standardized sizes, ensuring compatibility with a wide range of applications. Maintaining tight tolerances is essential to achieve a proper fit and sealing function.

metric wiper seals

4. Dynamic vs. Static Applications While most wiper seals are designed for dynamic applications (where movement occurs), some are adapted for static situations. Understanding the specific application helps determine the appropriate seal design.

Applications Across Industries

Metric wiper seals find use in various applications, including

- Hydraulic Systems In construction equipment, agricultural machinery, and industrial presses, wiper seals protect hydraulic cylinders from contaminants, ensuring optimal performance and safety.

- Automotive In automotive engineering, wiper seals are employed in brake systems, power steering units, and suspension systems, where they help reduce maintenance needs and improve reliability.

- Aerospace In aircraft, where precision is critical, wiper seals help maintain the integrity of hydraulic systems subject to extreme conditions.

- Manufacturing In industrial machinery, wiper seals are essential to maintain clean operation environments, significantly impacting productivity and efficiency.

Maintenance and Replacement

Regular maintenance of systems using wiper seals is crucial for identifying wear and tear. Inspecting wiper seals during routine checks can prevent costly downtime and ensure that the machinery operates reliably. Replacing worn-out seals in a timely manner helps maintain optimal performance and prolongs the life of the equipment.

Conclusion

Metric wiper seals serve as integral components in maintaining the efficiency and reliability of hydraulic and pneumatic systems across various industries. Their standardized design promotes compatibility and improves global sourcing of parts. As technology advances, the materials and designs of metric wiper seals continue to improve, pushing the boundaries of what is possible in machine performance and longevity. By understanding and implementing the correct wiper seals, engineers and manufacturers can ensure that their systems remain operational in the face of contaminants and wear, ultimately benefiting their bottom line.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories