Nov . 08, 2024 05:43 Back to list

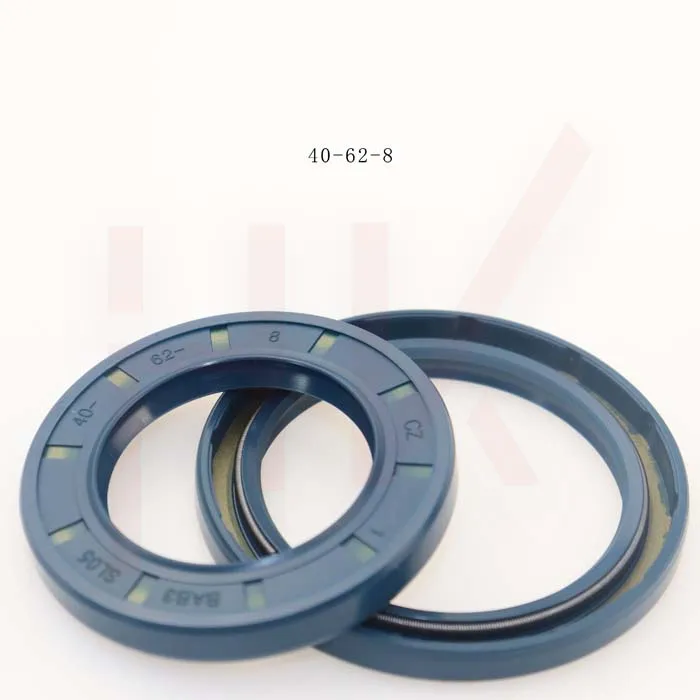

High-Performance Metric Rod Wiper Seals for Efficient Sealing Solutions

Understanding Metric Rod Wiper Seals Essential Components in Hydraulic Systems

In the world of hydraulic systems, the efficient sealing of fluids is critical to ensure optimal performance and longevity of equipment. Among the various sealing solutions available, metric rod wiper seals play a pivotal role. These seals are specifically designed to prevent the ingress of contaminants, thereby protecting hydraulic cylinders and ensuring they operate effectively under pressure.

The Functionality of Wiper Seals

Wiper seals, also known as scrapers, serve a fundamental function in hydraulic applications. They are primarily installed at the outer end of hydraulic cylinders, where the piston rod extends and retracts. Their main job is to remove dirt, dust, and moisture from the rod's surface before it enters the hydraulic cylinder. This prevention of contaminants is crucial, as even tiny particles can severely damage the internal components of the hydraulic system, leading to failures and costly maintenance.

Design and Material Considerations

Metric rod wiper seals are engineered with precision to accommodate various rod sizes and working conditions. They are often made from durable elastomeric materials that can withstand extreme temperatures, pressures, and exposure to various hydraulic fluids. Common materials used include nitrile rubber (NBR), polyurethane (PU), and fluorocarbon (FKM), each offering different advantages depending on the application.

The design of these seals can vary, but they typically feature a lip that contacts the rod surface, creating a tight seal while also effectively scraping away contaminants. The choice of design—be it single or double lip—depends on the specific requirements of the application. A double-lip design, for instance, provides enhanced protection against dirt and moisture ingress, making it more suitable for harsh operating environments.

Importance in Hydraulic System Efficiency

metric rod wiper seals

The significance of metric rod wiper seals extends beyond mere protection. They play a crucial role in enhancing the overall efficiency of hydraulic systems. By keeping the hydraulic cylinder clean, these seals help maintain consistent performance and reduce the risk of hydraulic fluid leaks. Furthermore, by minimizing wear on the rod surface, they extend the lifespan of hydraulic components, reducing replacement costs and downtime.

In many industrial applications, maintaining the integrity of hydraulic systems is paramount. Hydraulic cylinders are used in various machinery, from construction equipment to manufacturing systems. Any failure in these systems can halt production, leading to significant financial losses. Thus, investing in high-quality metric rod wiper seals is essential for any organization relying on hydraulic technology.

Selecting the Right Wiper Seal

When choosing metric rod wiper seals, it is crucial to consider several factors. First, the rod’s diameter and the operating environment—temperature, pressure, and the presence of specific chemicals—should be taken into account. Additionally, the speed of the rod's movement can influence the seal's design selection. A faster-moving rod may require a wiper seal with a different lip geometry to ensure optimal performance.

It's also advisable to consult with manufacturers or specialists who can provide insights into the best sealing solutions for specific applications. With proper selection and installation, metric rod wiper seals can significantly enhance the reliability and efficiency of hydraulic systems.

Conclusion

Metric rod wiper seals are indispensable components in maintaining the integrity of hydraulic systems. By preventing the ingress of contaminants, these seals not only protect the hydraulic cylinders but also ensure optimal performance and longevity of the machinery involved. Understanding the functionalities, materials, and selection criteria for these seals is vital for anyone involved in hydraulic system design and maintenance. By prioritizing the right sealing solutions, organizations can enhance their operational efficiency and reduce long-term costs, making the most of their hydraulic technology.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories