Oct . 11, 2024 23:07 Back to list

Innovative Metric Rod Wiper Solutions for Enhanced Performance and Reliability

Understanding Metric Rod Wipers An Essential Component in Precision Mechanics

In today’s world, precision mechanics and manufacturing processes rely heavily on various components that ensure efficiency, cleanliness, and functionality. One such component that plays a critical role in hydraulic systems, machinery, and equipment is the metric rod wiper. Despite being a seemingly minor part, the wiper is essential for the longevity and performance of hydraulic cylinders, ensuring that contaminants are kept at bay.

What are Metric Rod Wipers?

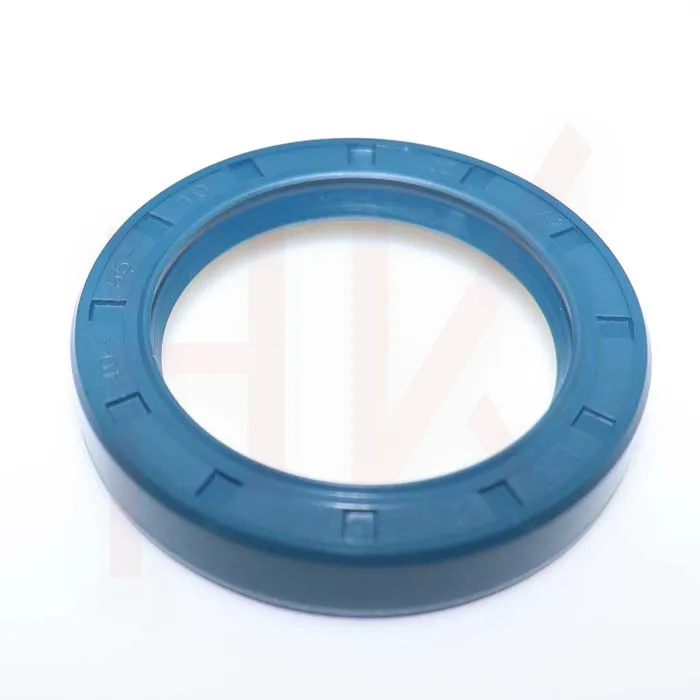

Metric rod wipers, also known as rod seals or scrapers, are specialized sealing elements that protect the rod of hydraulic cylinders. They are designed to fit metric dimensions, hence the term “metric.” The primary function of these wipers is to scrape off any dirt, dust, or debris from the rod’s surface as it extends and retracts. This action is vital because even the smallest contaminants can lead to increased wear and tear on the sealing surfaces, causing the hydraulic system to fail prematurely.

Design and Materials

Metric rod wipers come in various designs and materials to accommodate different applications and environments. The most common materials include polyurethane, rubber, and nitrile, each offering unique properties, such as resistance to wear, temperature, and chemical exposure. The design often features a lip or edge that contacts the rod, allowing for effective wiping action while maintaining a secure seal.

The choice of material and design largely depends on the working conditions, including the type of fluids used, operating temperature ranges, and the presence of any aggressive chemicals. For example, in environments where temperatures fluctuate significantly, a high-temperature resistant material is crucial.

Functionality and Performance

The primary function of metric rod wipers is to prevent contaminants from entering the hydraulic cylinder

. However, they also contribute to reducing friction between moving parts, which is vital for smooth operations. The wipers create a dynamic seal that manages the balance between fluid retention and the expulsion of dirt, thereby enhancing the overall efficiency of hydraulic systems.metric rod wiper

Moreover, metric rod wipers play a role in reducing hydraulic fluid leaks. By keeping contaminants at bay and ensuring a proper seal, they help maintain pressure within the system, which is crucial for optimal performance. This, in turn, contributes to lower maintenance costs and prolongs the life of the equipment.

Applications of Metric Rod Wipers

Metric rod wipers are prevalent in various industries, including automotive, aerospace, construction, and manufacturing. In the automotive industry, they are used in hydraulic brakes, steering systems, and suspension components. In aerospace applications, they ensure the reliability of hydraulic systems critical for flight control mechanisms.

In construction and heavy machinery, hydraulic cylinders equipped with metric rod wipers are commonplace. These systems need to operate under high pressure and must withstand harsh environmental conditions, making the quality of rod wipers a vital consideration. The durability and effectiveness of these components directly influence operational safety and equipment reliability.

Challenges and Considerations

While metric rod wipers are robust components, they are not immune to wear and tear. Factors such as improper installation, incompatible materials, and extreme operating conditions can lead to premature failure. Regular maintenance and inspections are essential to ensure that these wipers function correctly and to replace them as necessary before they fail.

Additionally, understanding the specific needs of an application is paramount when selecting the correct wiper. Factors like the rod diameter, speed of operation, and fluid characteristics must be considered to ensure optimal performance.

Conclusion

In conclusion, metric rod wipers are small yet significant components that play a crucial role in the functionality of hydraulic systems. Their ability to prevent contamination, reduce friction, and minimize leaks makes them indispensable in various industries. As technology advances and the demand for precision increases, the importance of these components will only grow. Ensuring that the right materials and designs are used will help maximize the efficiency and lifespan of hydraulic systems, ultimately benefiting manufacturers and operators alike.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories