Dec . 11, 2024 11:17 Back to list

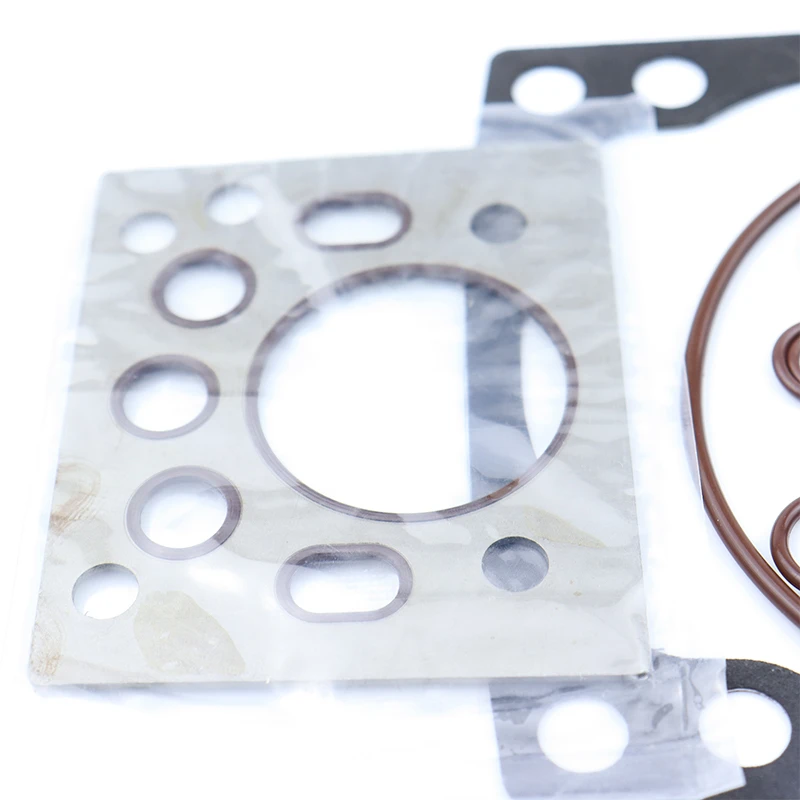

metal wiper seal

Understanding Metal Wiper Seals Applications and Benefits

In the realm of mechanical engineering and industrial applications, seals play a pivotal role in ensuring the efficiency and longevity of machinery. One often overlooked yet crucial component in this category is the metal wiper seal. This article delves into the characteristics, applications, and advantages of metal wiper seals, highlighting their importance in various industries.

What are Metal Wiper Seals?

Metal wiper seals are specialized sealing devices designed to prevent contamination from entering equipment while also keeping lubricants contained. Typically constructed from robust materials such as stainless steel or other alloys, these seals feature a flexible lip that can conform to the surface of the component it is sealing. This design allows for effective operation even in hostile environments where dirt, grime, and moisture are prevalent.

Key Characteristics

1. Durability One of the standout features of metal wiper seals is their exceptional durability. The metallic components are resistant to wear and tear, making them ideal for heavy-duty applications. They can withstand extreme temperatures and pressures, which often renders rubber or plastic seals ineffective.

2. Contamination Resistance The primary function of a wiper seal is to keep contaminants out. The lip of the seal acts as a barrier against dirt and other foreign materials that could jeopardize the integrity of the machinery. This is particularly important in high-precision applications where even the slightest contamination can lead to significant operational issues.

3. Customizability Metal wiper seals can be tailored to suit specific applications and environmental conditions. Manufacturers can adjust the thickness, profile, and material composition to meet the unique needs of different industries, ranging from automotive to aerospace.

4. Low Friction The design of metal wiper seals often incorporates features that minimize friction. This not only enhances the seal's longevity but also contributes to smoother operation of moving parts, reducing energy consumption and improving overall efficiency.

Applications of Metal Wiper Seals

The applications of metal wiper seals are vast and varied

. They are commonly found in industries such asmetal wiper seal

- Automotive Metal wiper seals are essential in vehicle systems, where they help maintain proper lubrication in engines and transmissions, protecting against contaminants that could cause damage.

- Aerospace The aerospace sector demands the highest standards of performance and safety. Metal wiper seals are used in hydraulic systems and landing gear mechanisms, where reliability is non-negotiable.

- Manufacturing In manufacturing equipment—like hydraulic cylinders and pneumatic systems—metal wiper seals ensure that machines continue to operate efficiently without the risk of contamination from industrial dust and debris.

- Oil and Gas Given the harsh conditions encountered in this sector, metal wiper seals are invaluable. They help safeguard drilling equipment and pipelines from abrasive materials and environmental stressors.

Advantages of Using Metal Wiper Seals

1. Extended Service Life Due to their superior durability, metal wiper seals tend to last longer than traditional rubber seals. This longevity translates to less frequent replacements and lower maintenance costs.

2. Enhanced Performance The ability to keep contaminants out while reducing friction enhances the overall performance of machinery, leading to improved operational efficiency.

3. Safety By ensuring that equipment operates smoothly and efficiently, metal wiper seals contribute to a safer working environment. This is crucial in industries where equipment failure could lead to hazardous situations.

4. Cost-Effectiveness Although the initial investment in metal wiper seals may be higher than that of traditional materials, their durability and low maintenance requirements result in lower total lifecycle costs.

In conclusion, metal wiper seals are essential components that contribute significantly to the reliability and efficiency of various industrial systems. Their unique combination of durability, contamination resistance, and adaptability makes them an invaluable choice for a wide range of applications, ensuring operational excellence in challenging environments. As technology continues to advance, the significance of such components will only grow, further emphasizing the need for quality sealing solutions in various industries.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories