Nov . 25, 2024 08:24 Back to list

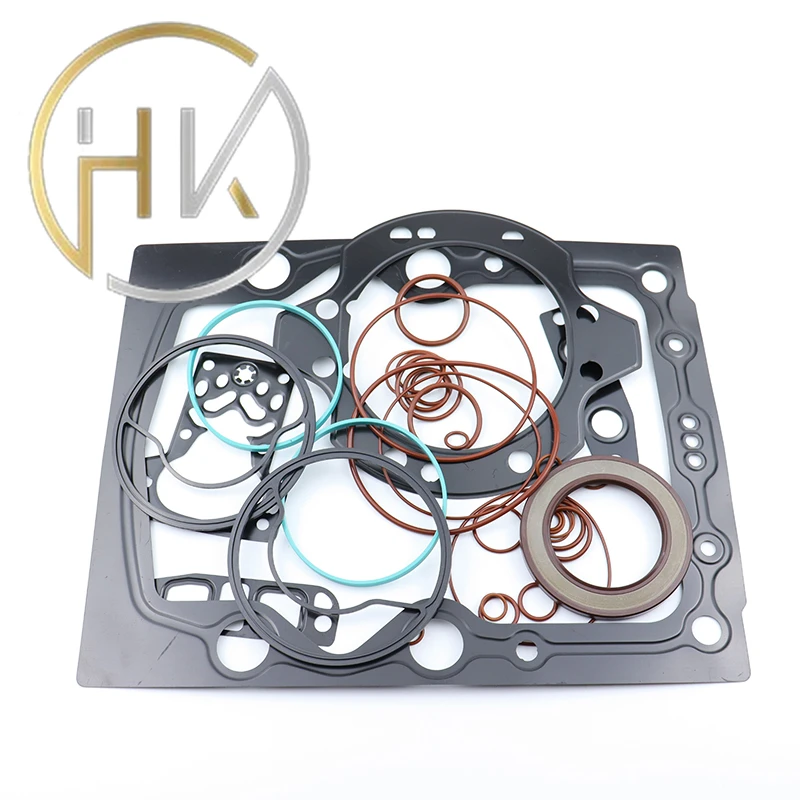

metal oil seal

The Importance of Metal Oil Seals in Industrial Applications

In today's industrial landscape, the reliability and efficiency of machinery are paramount to success. Among various components that contribute to the optimal functioning of machines, metal oil seals play a crucial role. These seals are essential for preventing the leakage of lubricants and providing protection against contaminants, thus ensuring that machinery operates smoothly and efficiently.

Construction and Design

Metal oil seals are typically composed of several materials, including rubber compounds and metallic elements. The combination of these materials allows for high resistance to temperature fluctuations, pressure variations, and chemical exposure. The outer casing, which is usually made of steel or aluminum, provides strength and rigidity, while the elastomeric sealing lip offers flexibility and adaptability. This unique design allows metal oil seals to create a robust barrier against the intrusion of dirt, dust, and moisture, thereby protecting critical components within machinery.

One of the distinguishing features of metal oil seals is their ability to maintain an effective seal under a wide range of operating conditions. This adaptability makes them indispensable in environments where fluctuations in temperature and pressure are common, such as in automotive, aerospace, and manufacturing applications.

Benefits of Metal Oil Seals

1. Leak Prevention The primary function of metal oil seals is to prevent lubricant leaks. Lubricants play a critical role in reducing friction between moving parts, minimizing wear and tear, and extending the life of equipment. A well-sealed machine helps maintain optimal lubrication, ensuring that components operate smoothly and efficiently.

metal oil seal

2. Contamination Control Metal oil seals are designed to protect machinery from contaminants, such as dirt, dust, and water. By keeping these harmful elements out, metal oil seals help preserve the integrity of lubricants and the overall functionality of the equipment. Contamination can lead to premature wear and failure of components, resulting in costly repairs and downtime.

3. Durability and Longevity Metal oil seals are known for their durability. Their robust construction allows them to withstand harsh operating conditions, which is particularly important in heavy-duty applications. A high-quality seal can last for years, reducing the need for frequent replacements and maintenance.

4. Cost-Effectiveness While the initial investment in metal oil seals may be higher than that of traditional rubber seals, their long-term benefits often outweigh the costs. The reduced risk of leaks and contamination can lead to lower maintenance costs, fewer repairs, and less downtime, ultimately increasing the overall profitability of industrial operations.

Applications Across Industries

Metal oil seals find applications in a wide variety of industries, including automotive, aerospace, marine, and manufacturing. In the automotive industry, they are used in engines, transmissions, and differentials to ensure the efficient operation of vehicles. In aerospace, they are essential for maintaining the integrity of aircraft systems under extreme conditions. Likewise, in manufacturing, metal oil seals are employed in various machinery to enhance operational efficiency and reliability.

Conclusion

In conclusion, metal oil seals play an indispensable role in protecting machinery and ensuring efficient operation across many industries. Their robust construction and design enable them to withstand harsh conditions while providing the dual benefits of leak prevention and contamination control. As industries continue to evolve and demand higher reliability from their machinery, the role of metal oil seals will only become more critical. Investing in quality metal oil seals can lead to significant long-term savings and improved operational efficiency, making them a wise choice for any industrial application.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories