Oct . 31, 2024 22:39 Back to list

Innovative Solutions for Durable Metal Clad Wiper Seals in Harsh Environments

Understanding Metal Clad Wiper Seals A Comprehensive Overview

In the world of mechanical sealing solutions, metal clad wiper seals stand out due to their exceptional durability and effectiveness in a variety of applications. These seals are engineered to provide reliable sealing and protection for moving parts, especially in harsh environments where traditional seals might fail.

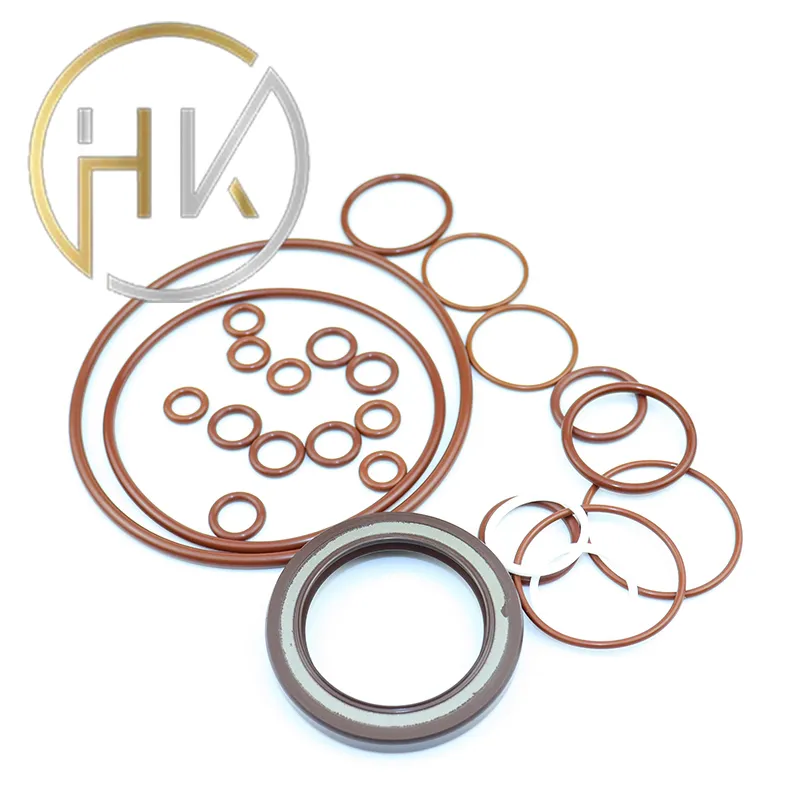

Metal clad wiper seals typically consist of two main components a flexible sealing element and a metal casing. The flexible component is often made of high-performance elastomers or polymers that ensure a tight fit against rotating or reciprocating shafts. This part is primarily responsible for preventing contaminants such as dirt, dust, and moisture from entering sensitive areas. The metal casing, typically made of stainless steel or other corrosion-resistant materials, adds structural integrity and enables the seal to withstand higher pressures and temperatures.

One of the primary advantages of metal clad wiper seals is their ability to provide superior protection against wear and tear. In industrial applications, machinery is often subjected to extreme conditions, including high speeds, aggressive chemicals, and abrasive materials. The robust design of metal clad wiper seals ensures they can maintain their integrity even under these demanding circumstances. As a result, they help prolong equipment life, reduce maintenance costs, and improve overall efficiency.

metal clad wiper seals

Furthermore, the design of these seals allows for easy installation and replacement. This attribute is particularly beneficial in maintenance-intensive environments, where down-time must be minimized. The metal clad wiper seals can often be tailored to fit specific dimensions and application requirements, ensuring a perfect fit right from the start.

In addition to industrial applications, metal clad wiper seals are extensively used in automotive and aerospace industries. They are crucial in protecting components like actuators, hydraulic cylinders, and pumps, which are vital for optimal performance and safety. In these sectors, reliability is paramount, and the use of metal clad wiper seals ensures that high standards are met.

Environmental concerns have also prompted manufacturers to consider the use of metal clad wiper seals. These seals can be made with environmentally friendly materials, and their durability means that fewer replacements are needed over time. This can contribute to waste reduction and lower the environmental impact of industrial operations.

In summary, metal clad wiper seals offer a host of benefits, making them a valuable component in a range of applications where reliability and performance are critical. Their unique combination of a flexible sealing element and a protective metal casing allows them to effectively keep contaminants at bay while withstanding the rigors of demanding environments. As industries continue to evolve and face new challenges, the importance of robust sealing solutions like metal clad wiper seals will only increase, highlighting their essential role in modern engineering and maintenance strategies. For those seeking to improve efficiency and reliability in their machinery, investing in metal clad wiper seals is a decision that promises significant returns.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories