Sep . 02, 2024 21:31 Back to list

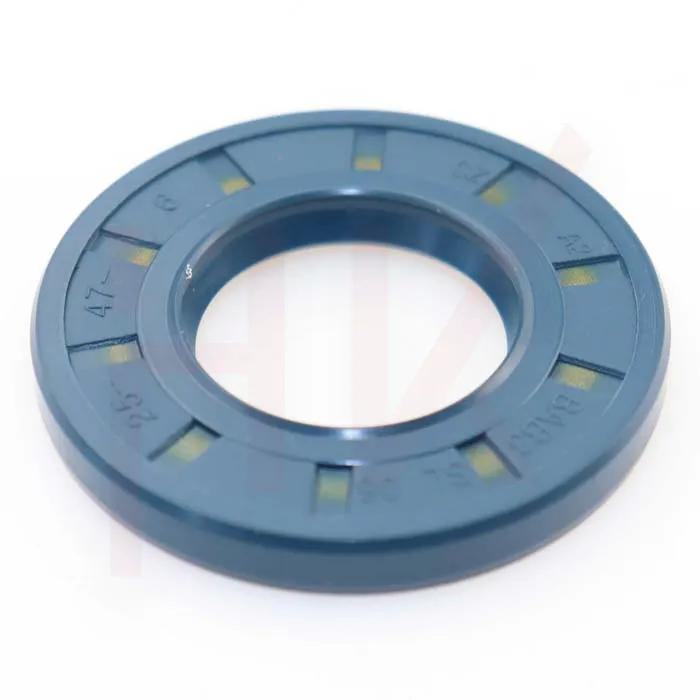

mechanical seal repair kit

Understanding Mechanical Seal Repair Kits

Mechanical seals play a crucial role in various industrial applications by preventing leaks in rotating equipment. They are essential components in pumps, compressors, and mixers, where fluid containment is paramount. Over time, wear and tear can occur due to environmental factors, operational stresses, and material fatigue, necessitating repair or replacement. This is where mechanical seal repair kits come into play.

What is a Mechanical Seal Repair Kit?

A mechanical seal repair kit is a comprehensive package containing all the necessary components to repair or replace a mechanical seal. These kits are designed to restore the functionality of a seal without the need for complete equipment replacement. They typically include items such as seals, springs, O-rings, gaskets, and installation tools. The specific contents may vary based on the kit's intended application and the type of mechanical seal.

Importance of Repair Kits

Mechanical seal repair kits offer several advantages

1. Cost-Effectiveness Repairing a mechanical seal with a kit is generally more economical than purchasing a new seal or replacing the entire pump or equipment. This cost-saving benefit can be significant for industries that rely heavily on rotating equipment.

2. Quick Maintenance Having a repair kit on hand allows for rapid response to seal failures. Downtime in manufacturing can lead to substantial losses, so being able to quickly repair equipment helps maintain productivity.

3. Customization Many repair kits are available in various configurations, catering to different types and sizes of mechanical seals. This flexibility allows facility managers to stock the appropriate kits for their specific equipment needs.

mechanical seal repair kit

4. Improved Reliability By using a repair kit specifically designed for a certain type of seal, users can ensure that the repair meets the original specifications. This can help restore the reliability of the equipment and prevent future failures.

How to Use a Repair Kit?

Repairing a mechanical seal using a repair kit typically involves several steps

1. Assessment The first step is to assess the damage to the seal and identify the components that need replacement. This may require disassembling the equipment to inspect the mechanical seal closely.

2. Preparation Once the damaged components are identified, gather the necessary tools and follow the manufacturer's guidelines for the repair. Ensure the work area is clean to avoid contamination during the repair process.

3. Replacement Carefully remove the old seal components and install the new parts from the repair kit. Make sure to follow the assembly instructions, paying close attention to alignment and torque specifications.

4. Testing After the seal is installed, reassemble the equipment and conduct a leak test to ensure that the repair was successful and that there are no leaks.

Conclusion

Mechanical seal repair kits are an invaluable resource for maintaining the efficiency and reliability of industrial machinery. By understanding the importance and proper usage of these kits, facility managers can save time and money while ensuring that their equipment operates smoothly. Regular maintenance and timely repairs using these kits not only enhance the lifespan of machinery but also contribute to overall operational effectiveness in various industrial settings.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories