Aug . 28, 2024 23:37 Back to list

lip seal suppliers

Understanding Lip Seal Suppliers A Comprehensive Guide

When it comes to industrial applications, the importance of efficient sealing solutions cannot be overstated. Among these, lip seals, also known as radial lip seals or oil seals, play a crucial role in preventing leakage of lubricants and protecting machinery from contaminants. The choice of the right lip seal supplier is vital for the longevity and performance of machinery. This article explores the key considerations when selecting lip seal suppliers and highlights the benefits of partnering with reputable providers.

What Are Lip Seals?

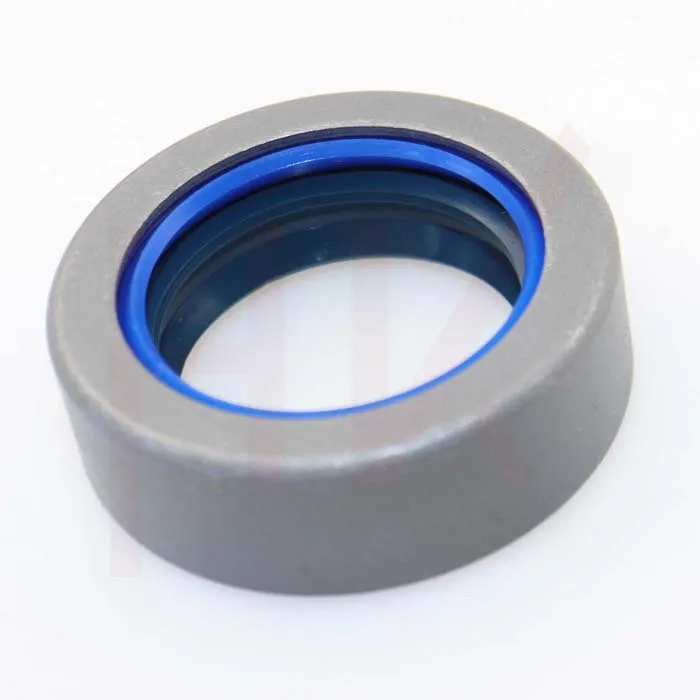

Lip seals are designed to seal cylindrical shafts and housings, providing a barrier against external contaminants while retaining lubrication. They are commonly used in various applications, including automotive, aerospace, manufacturing, and agricultural machinery. The design of a lip seal consists of a flexible lip made from materials such as rubber, silicone, or polyurethane, which conforms to the shaft's surface to create a tight seal.

Importance of Quality Lip Seal Suppliers

1. Material Expertise The performance of a lip seal largely depends on the materials used in its construction. A reputable supplier should offer a range of high-quality materials that can withstand specific operating conditions, such as temperature fluctuations, chemical exposure, and pressure. Knowledgeable suppliers can help customers select the most suitable materials for their unique applications.

lip seal suppliers

2. Customization Options Different industries have varying sealing requirements. A reliable lip seal supplier should provide customization options, including size, design, and material formulation. This flexibility ensures that customers receive products tailored to their specific needs, leading to better performance and enhanced durability.

3. Technical Support and Consultation A good supplier goes beyond merely providing products; they also offer technical support and consultation. This can involve helping customers understand the best sealing solutions for their applications, troubleshooting issues, and providing guidance on installation and maintenance. Suppliers with a strong technical background can significantly facilitate the decision-making process for their clients.

4. Testing and Quality Assurance The best lip seal suppliers invest in rigorous testing and quality assurance processes. They should conduct various tests, such as pressure, temperature, and wear resistance, to ensure that their seals meet industry standards. Suppliers that are certified by recognized quality standards, such as ISO 9001, demonstrate their commitment to providing high-quality products.

5. Reliability and Reputation Before selecting a lip seal supplier, it’s essential to consider their reputation in the industry. Look for suppliers with a proven track record of reliability and customer satisfaction. Reviews and testimonials from other clients can provide valuable insights into the supplier's performance, responsiveness, and product quality.

Conclusion

Choosing the right lip seal supplier is critical for any business that relies on effective sealing solutions. By focusing on material expertise, customization options, technical support, rigorous testing, and supplier reputation, companies can ensure they partner with a reliable provider. In today's competitive industrial landscape, the right lip seal can make a significant difference in operational efficiency and equipment longevity, highlighting the importance of making informed supplier choices. Whether for an automotive manufacturing line or aerospace equipment, the right lip seal can ultimately lead to better performance and reduced costs.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories