Nov . 24, 2024 14:57 Back to list

industrial oil seals

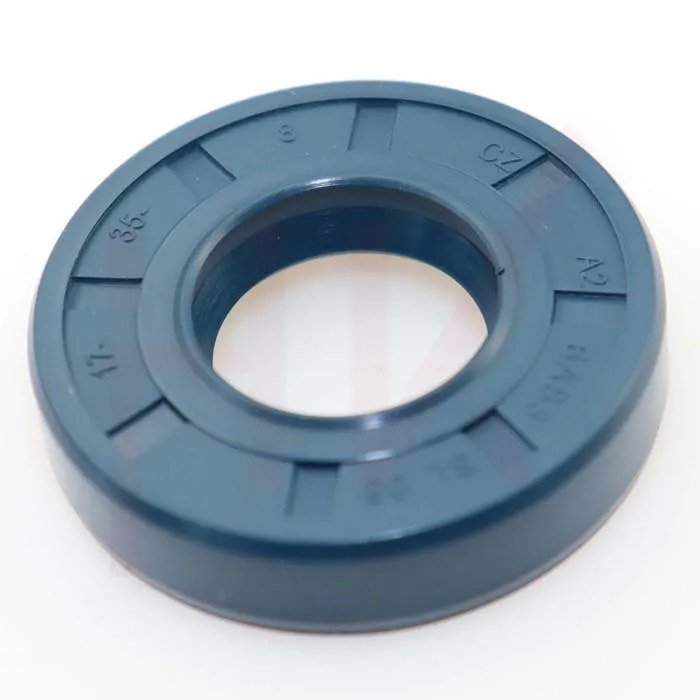

Understanding Industrial Oil Seals Importance, Types, and Applications

Industrial oil seals are vital components employed in various machinery and equipment to prevent the leakage of lubricating oils while also protecting against contaminants such as dirt and moisture. These seals play a crucial role in maintaining the efficiency and longevity of mechanical systems, particularly in industries that rely on heavy machinery, automotive applications, and manufacturing processes.

The Importance of Industrial Oil Seals

In any mechanical system, lubrication is essential for minimizing friction between moving parts. Without proper lubrication, components can wear out quickly, leading to increased maintenance costs and unscheduled downtimes. Oil seals, therefore, are designed to retain the lubricating oil needed for optimal operation while also preventing external contaminants from entering the system. This dual function is critical for ensuring the reliability and efficiency of machinery.

Moreover, industrial oil seals can contribute to energy efficiency. When a system is well-lubricated and free from contaminants, it operates more smoothly and requires less energy to function. This efficiency can lead to significant cost savings over time, making the selection of quality oil seals an important consideration for any industrial operation.

Types of Industrial Oil Seals

Industrial oil seals come in various designs and materials, each tailored to specific applications. The most common types include

1. Radial Oil Seals These seals consist of a flexible lip that makes contact with a rotating shaft and is designed to withstand both radial and axial loads. Radial oil seals are widely used in automotive applications and rotating equipment, such as pumps and motors.

2. Lip Seals Available in various shapes and sizes, lip seals employ a lip that compresses against the shaft, creating a tight seal. They are effective in preventing leakage of lubricants while also keeping contaminants at bay.

3. U-Cup Seals These seals feature a U-shaped cross-section and are commonly used in hydraulic applications. U-cup seals provide excellent sealing capabilities, particularly in dynamic applications where they must accommodate movement.

industrial oil seals

4. O-Rings While not traditional oil seals, O-rings serve a similar function and are often used to create seals in static and dynamic applications. They are versatile, widely available, and utilized in various industries.

5. Mechanical Seals Found in pumps and other rotating equipment, mechanical seals consist of two faces that slide against each other to create a tight seal. They are particularly effective in preventing the leakage of fluids in high-pressure environments.

Applications of Industrial Oil Seals

Industrial oil seals find application across a multitude of sectors, including

- Automotive Industry Used in engines, transmissions, and differentials, oil seals help retain lubrication and protect components from contamination.

- Manufacturing In factories, oil seals are crucial for equipment like conveyors, motors, and pumps, safeguarding them from dirt and maintaining optimal performance.

- Aerospace The aerospace industry relies heavily on high-performance oil seals to ensure the reliability of aircraft systems, where even minor failures can lead to catastrophic results.

- Marine Applications Oil seals are used in maritime equipment to protect against saltwater intrusion and maintain the necessary lubrication for safe operation.

Conclusion

In conclusion, industrial oil seals play an indispensable role in the functioning of various mechanical systems. By preventing oil leaks and shielding internal components from external contaminants, these seals enhance the performance, efficiency, and lifespan of machinery. Understanding the different types of oil seals and their applications is vital for industries looking to optimize their operations and reduce maintenance costs. As technology continues to evolve, so too will the design and functionality of oil seals, ensuring that they remain a key component in the industrial landscape.

-

Wiper Oil Seal: Our Commitment to Clean Hydraulics

NewsAug.13,2025

-

Hydraulic Oil Seal for Self Discharging Cars

NewsAug.13,2025

-

Hub Oil Seal for Agricultural Tractor Hubs

NewsAug.13,2025

-

Skeleton Oil Seal with NBR Material

NewsAug.13,2025

-

Rotary Lip Seal for High Pressure Applications

NewsAug.13,2025

-

Cylinder Seal Kits Our Legacy of Hydraulic Trust

NewsAug.13,2025

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

Products categories