Nov . 18, 2024 03:12 Back to list

Innovative Solutions for Durable Industrial Oil Seals in Modern Machinery Applications

Understanding Industrial Oil Seals Importance and Applications

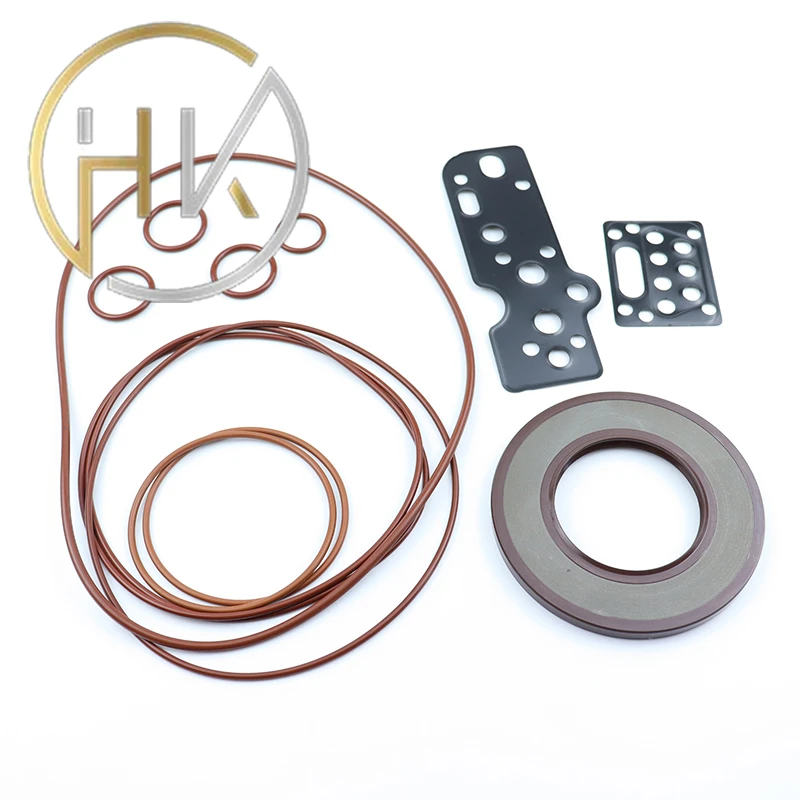

Industrial oil seals are critical components used in machinery and equipment across various industries. Their primary function is to prevent the leakage of lubricants and fluids while keeping contaminants out, thereby ensuring the durability and efficiency of machines. Understanding oil seals, their types, and applications can greatly enhance operational efficiency and equipment longevity.

What Are Oil Seals?

Oil seals, also known as shaft seals or rotary seals, are mechanical devices designed to seal the interface between stationary and moving parts in machinery. Typically made of rubber, silicone, or other elastomeric materials, these seals are engineered to withstand a variety of temperature and pressure conditions. The design of an oil seal includes a sealing lip that provides a tight fit against the shaft while minimizing friction. This design prevents oil from escaping and protects against dirt, dust, and moisture.

Types of Oil Seals

There are several types of oil seals, each suited for specific applications

1. Rubber Oil Seals Commonly used in automotive applications, these seals are known for their elasticity and durability against various operating conditions.

2. Metal-Cased Oil Seals These seals provide additional strength and rigidity, making them ideal for heavy machinery and industrial applications.

3. Spring-Loaded Oil Seals Equipped with a spring that enhances the sealing lip’s contact with the shaft, these seals are used in high-speed applications where traditional seals might fail.

industrial oil seals

4. PTFE Seals Known for their chemical resistance and high-temperature tolerance, PTFE seals are suited for harsh operating environments.

Applications of Oil Seals

Oil seals are essential in numerous industries, including

- Automotive Used in engines, transmissions, and differentials, oil seals help maintain proper lubrication and prevent fluid leaks that could compromise performance and safety.

- Manufacturing In industrial machines, oil seals protect bearings and other critical components from contamination, ensuring smooth operation and prolonging equipment life.

- Aerospace The aviation industry relies on oil seals to operate efficiently in high-pressure and temperature environments, maintaining the integrity of systems such as hydraulic and fuel systems.

- Marine In marine applications, where exposure to saltwater and corrosive elements is a concern, specialized oil seals provide necessary protection against leaks and contamination.

Conclusion

The importance of industrial oil seals cannot be overstated. They play a vital role in ensuring the smooth operation of various machinery and equipment, safeguarding them against leaks and contaminants that could lead to expensive repairs and downtime. By selecting the appropriate type of oil seal for specific applications, industries can enhance efficiency, minimize maintenance costs, and extend the lifespan of their equipment. As technology advances, the materials and designs of oil seals continue to evolve, promising even greater performance and reliability in the future. Understanding these components is essential for anyone involved in machinery maintenance and operation, ultimately contributing to safer and more efficient industrial practices.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories