Sep . 22, 2024 18:45 Back to list

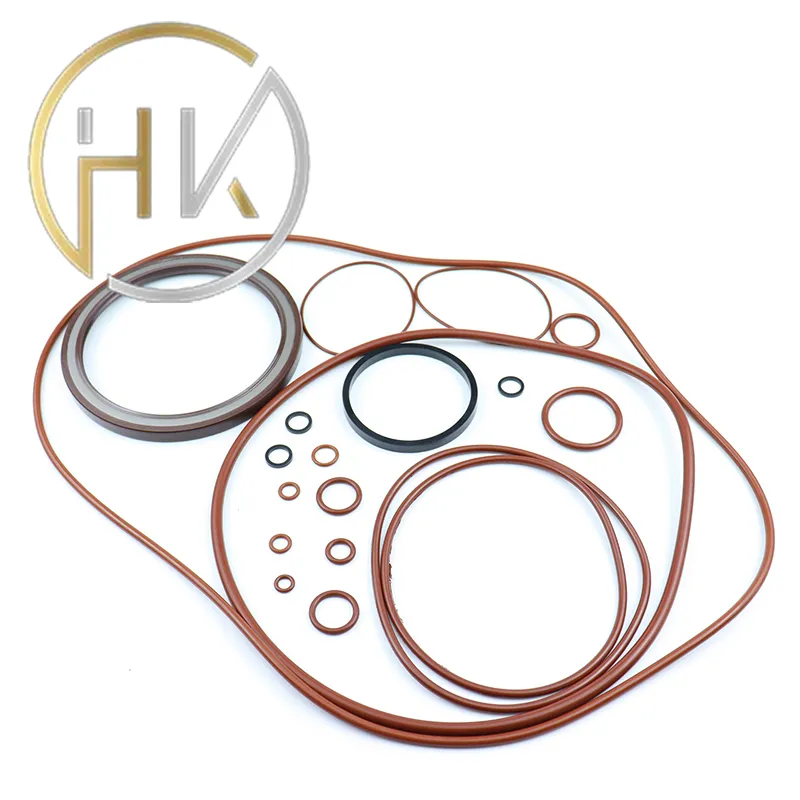

hydraulic wiper seal

Hydraulic wiper seals are essential components in hydraulic systems, serving to protect critical parts from dirt, debris, and other contaminants. These seals are typically used in hydraulic cylinders, where they help maintain the integrity and efficiency of the system. Understanding their design, functionality, and maintenance is vital for anyone involved in hydraulic machinery or equipment.

The primary function of a hydraulic wiper seal is to prevent external contaminants from entering the hydraulic system while allowing the internal hydraulic fluid to flow freely. They are usually located at the exposed end of the hydraulic cylinder and are designed with a wiping action that keeps the rod clean as it extends and retracts. This is crucial, as any particles that enter the system can cause significant wear and tear on internal components, leading to system failures and costly repairs.

Hydraulic wiper seals are made from various materials, including rubber, polyurethane, and other elastomers. The choice of material largely depends on the operating environment, temperature, and the type of hydraulic fluid used. For instance, in high-temperature applications, seals made from special heat-resistant compounds may be necessary to ensure longevity and reliability. Moreover, the design of the wiper seal can vary, with options available that incorporate features such as dual-lip configurations or dynamic profiles to enhance their effectiveness.

hydraulic wiper seal

Proper installation and maintenance of hydraulic wiper seals are also critical. Installing a seal incorrectly can lead to leaks, which can significantly affect the performance of the hydraulic system. Regular inspections should be conducted to identify any signs of wear or damage, such as cracks or abrasions. If a wiper seal is compromised, it should be replaced promptly to prevent further issues.

In conclusion, hydraulic wiper seals play a pivotal role in the longevity and efficiency of hydraulic systems. By preventing contaminants from entering the system and ensuring the smooth operation of the hydraulic cylinders, these seals help maintain the overall performance and reliability of machinery. For those working with hydraulic equipment, understanding the importance of wiper seals and ensuring they are properly maintained is crucial to avoid costly downtime and repairs. Investing in quality seals and adhering to maintenance best practices will contribute to the seamless operation of hydraulic systems in various applications.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories