Nov . 22, 2024 02:48 Back to list

hydraulic seal replacement

Hydraulic Seal Replacement A Comprehensive Guide

Hydraulic systems are pivotal in various industrial applications, from manufacturing to construction. These systems rely heavily on seals to maintain pressure and prevent leaks. Over time, hydraulic seals can wear out or become damaged, leading to costly downtime and inefficient operation. This article will explore the necessity of hydraulic seal replacement, the process involved, and tips for ensuring long-lasting performance.

Understanding Hydraulic Seals

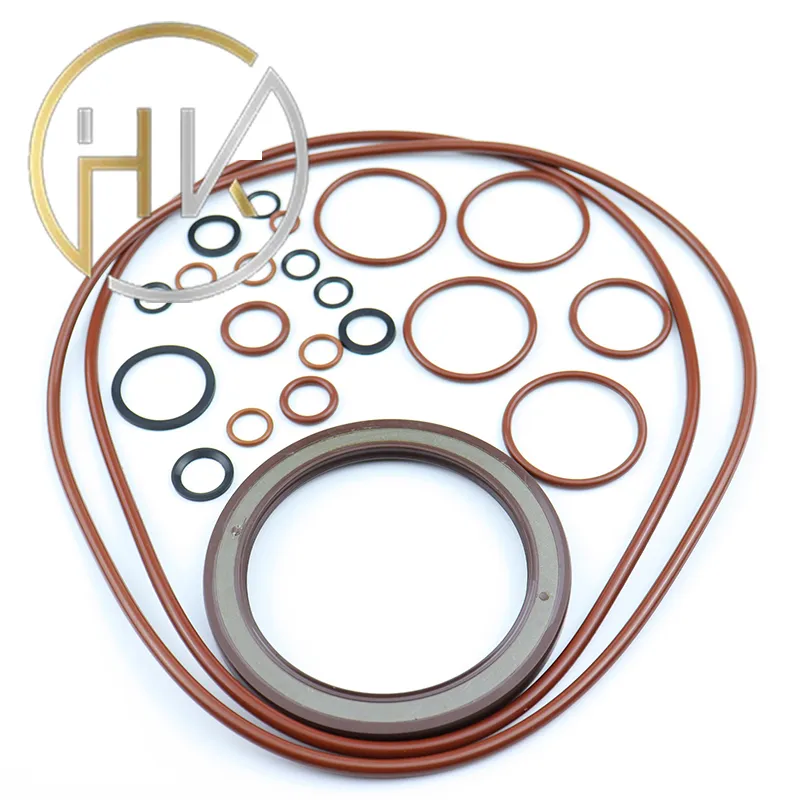

Hydraulic seals are designed to retain fluid within a hydraulic system while preventing external contaminants from entering. They come in various types, including O-rings, lip seals, and rod seals. The choice of seal depends on the specific application, pressure requirements, and fluid properties. A well-functioning seal is crucial for the overall efficiency and safety of hydraulic systems.

Signs of Seal Wear

Detecting the signs of wear and tear on hydraulic seals is essential for preventing significant malfunctions. Common indicators include

1. Fluid Leaks The most obvious sign of a failing seal is fluid leakage. If you notice hydraulic fluid pooling around machinery or dripping from equipment, it’s a clear indication that seal replacement is necessary. 2. Decreased Performance A hydraulic system may show reduced efficiency if seals are damaged. This could manifest as slower operation, reduced lifting capacity, or erratic performance.

3. Increased Noise Unusual sounds, especially grinding or banging, can indicate that seals have failed, allowing contaminants to enter the hydraulic system.

4. Visual Damage Inspect seals regularly for cracks, wear, or deformation. Physical evidence of damage can help you determine their condition before a critical failure occurs.

The Replacement Process

Replacing hydraulic seals is a task that should be performed with care and precision. Here’s a step-by-step guide to ensure a successful replacement

1. Shut Down and Depressurize Before starting the replacement process, ensure that the hydraulic system is powered down and all accumulated pressure is released. This step is crucial for safety.

2. Disassemble the System Carefully disassemble the components surrounding the seal. Keep track of parts and their arrangement to ensure seamless reassembly.

hydraulic seal replacement

3. Remove the Old Seal Using appropriate tools, gently remove the damaged seal. Be cautious to avoid scratching the housing or rod, as this could lead to further seal failures.

4. Clean the Area Thoroughly clean the sealing surfaces to remove old seal remnants and contaminants. A clean workspace is vital for ensuring the new seal's effectiveness.

5. Install the New Seal Apply a thin layer of compatible lubricant to the new seal and its installation surface. This makes installation easier and helps prevent damage while inserting it into the housing.

6. Reassemble the System Once the new seal is in place, reassemble the components in the reverse order of disassembly. Ensure that all parts are securely fastened and that no items are forgotten.

7. Test the System After reassembly, conduct a pressure test to ensure that there are no leaks and that the system operates smoothly. Monitor the performance to confirm that the issue has been resolved.

Preventive Measures

To extend the lifespan of hydraulic seals and minimize the need for replacements, consider implementing preventive measures

- Regular Inspections Establish a routine inspection schedule to check seals for signs of wear. Early detection can save time and resources.

- Quality Seals Invest in high-quality seals that are compatible with your hydraulic fluids and environmental conditions. Quality products often provide longer service life.

- Proper Maintenance Regular maintenance of the hydraulic system, including fluid changes and cleanliness, can significantly reduce the wear on seals.

Conclusion

Hydraulic seal replacement is a critical maintenance task that can impact the efficiency and reliability of hydraulic systems. By recognizing the signs of wear, understanding the replacement process, and implementing preventive measures, you can ensure optimal performance and longevity of your equipment. Keeping your hydraulic systems well-maintained not only saves costs but also enhances safety and productivity in your operations.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories