Nov . 19, 2024 18:07 Back to list

Exploring the Importance and Functionality of Hydraulic Ram Seals in Machinery Systems

Understanding Hydraulic Ram Seals Essential Components for Performance and Durability

Hydraulic systems are integral to a vast array of machinery and equipment across various industries, from construction and manufacturing to transportation and aerospace. At the heart of these systems lies hydraulic ram seals, which are crucial for ensuring efficient operation and maintaining the performance of hydraulic equipment. This article delves into the importance of hydraulic ram seals, their types, functions, and factors influencing their performance.

What are Hydraulic Ram Seals?

Hydraulic ram seals are vital components designed to prevent fluid leakage and contamination within hydraulic cylinders. These seals are specifically crafted to accommodate the high pressures typically found in hydraulic systems, enabling the safe and effective functioning of various hydraulic applications. The primary purpose of these seals is to create a barrier that maintains pressure, ensuring that the hydraulic fluid remains contained within the system, thus facilitating smooth and efficient operation.

Types of Hydraulic Ram Seals

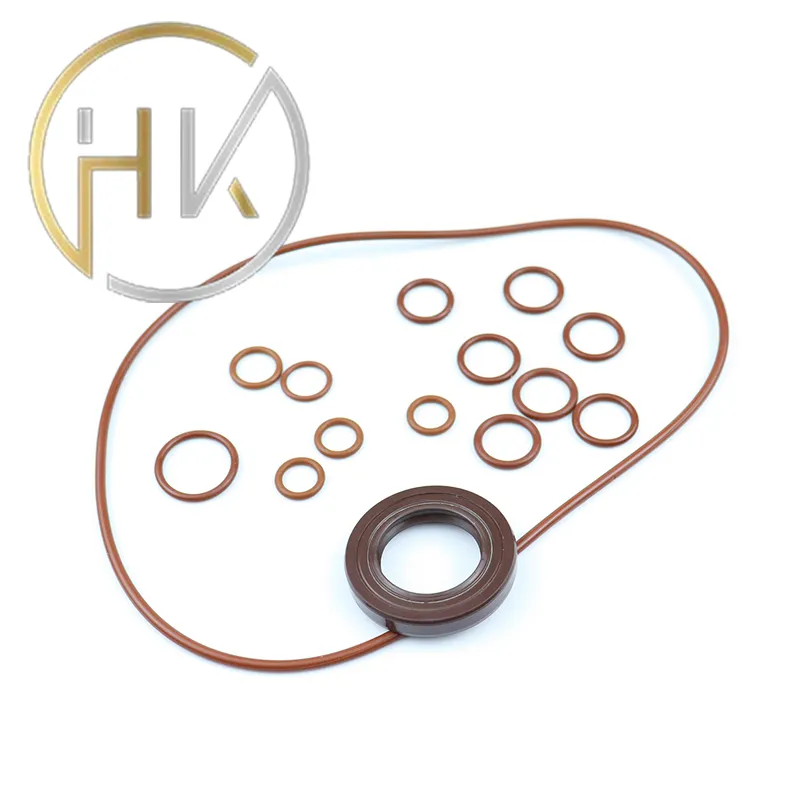

There are several types of hydraulic ram seals, each tailored to suit specific applications and conditions. The most common types include

1. O-rings These circular seals are commonly used in hydraulic ram applications due to their versatility, providing good sealing performance under various conditions. They are usually made from materials such as nitrile rubber, which can withstand the pressures and temperatures typical in hydraulic systems.

2. U-cups Designed for dynamic applications, U-cup seals provide a robust barrier against fluid leakage. Their design allows for better extrusion resistance, making them suitable for high-pressure environments.

3. Rod seals These seals specifically focus on preventing fluid from escaping the hydraulic cylinder when the rod is in motion. Commonly used in conjunction with backup rings, rod seals ensure optimal sealing by accommodating wear and tear over time.

4. Piston seals As the counterpart to rod seals, piston seals are designed to prevent leakage between the piston and the cylinder wall. They are vital for maintaining hydraulic pressure when the system is in operation, ensuring effective transmission of force.

5. Wear rings While not seals in the traditional sense, wear rings protect hydraulic seals from excessive wear. They help maintain proper alignment and reduce friction between moving parts, enhancing the longevity of the hydraulic system.

Importance of Choosing the Right Seal Material

hydraulic ram seals

The material selection for hydraulic ram seals is critical, as it directly affects the seal's performance and durability. Common materials include

- Nitrile Rubber (NBR) Known for its excellent resistance to oil and high temperatures, making it a popular choice for various hydraulic applications. - Fluoroelastomers (FKM) These materials offer superior chemical resistance, ideal for aggressive fluids and high-temperature environments. - Polyurethane Known for its elasticity and abrasion resistance, polyurethane seals are increasingly used in applications that experience high wear.

Selecting the appropriate material based on the specific operating conditions—such as temperature, pressure, and fluid compatibility—is essential for ensuring the longevity and effectiveness of hydraulic ram seals.

Factors Influencing Seal Performance

Several factors can significantly impact the performance of hydraulic ram seals

1. Pressure and Temperature High pressures and temperatures can lead to seal deformation and wear, necessitating regular inspection and potential replacement.

2. Fluid Compatibility The hydraulic fluid's chemical composition can adversely affect the seal material. It's crucial to ensure compatibility to prevent premature seal failure.

3. Installation Quality Improper installation can lead to early seal failure. Thus, it is essential to follow manufacturer guidelines and best practices during installation.

4. Maintenance Regular maintenance, including inspections for wear and leakage, can prolong the life of hydraulic ram seals and enhance overall system reliability.

Conclusion

Hydraulic ram seals play a pivotal role in the efficiency and reliability of hydraulic systems. Understanding the different types, materials, and factors influencing their performance helps in making informed decisions that ensure optimal operation and longevity of hydraulic equipment. By investing in the right seals and maintaining them properly, industries can reduce downtime, lower operational costs, and enhance the safety and performance of their hydraulic machinery.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories