Nov . 05, 2024 17:33 Back to list

hydraulic ram seals

Understanding Hydraulic Ram Seals Essential Components for Efficiency and Reliability

Hydraulic ram seals are critical components in hydraulic systems, playing a pivotal role in ensuring efficiency, reliability, and longevity of the machinery. As industries continue to rely on hydraulic systems for various applications—from construction machinery and manufacturing equipment to agricultural tools—the importance of understanding and maintaining hydraulic ram seals cannot be overstated.

What is a Hydraulic Ram?

A hydraulic ram is a device that utilizes the power of flowing water or other fluids to perform mechanical tasks, typically involving lifting or forcing substantial weights. It operates based on the principles of hydraulic pressure, allowing for effective transmission of force. The hydraulic ram relies on a series of seals to maintain pressure, prevent leaks, and ensure the smooth operation of the system.

The Role of Seals in Hydraulic Rams

Seals in hydraulic systems serve several essential functions

1. Preventing Leaks The primary purpose of hydraulic seals is to prevent the escape of hydraulic fluid from the system. A leak not only leads to fluid loss but can also compromise the system’s performance and safety.

2. Maintaining Pressure Hydraulic systems operate under high pressure, and seals are crucial in maintaining this pressure. If the seal fails, it could lead to significant drops in pressure, affecting the entire operation of the hydraulic ram.

3. Reducing Friction Hydraulic seals also minimize friction between moving parts. This is important for maintaining efficiency, as high friction can lead to overheating and increased wear on components.

4. Protecting Against Contamination Seals provide a barrier against dust, dirt, and other contaminants that could enter the hydraulic system. Contaminated hydraulic fluid can damage internal components and lead to costly repairs.

Types of Hydraulic Ram Seals

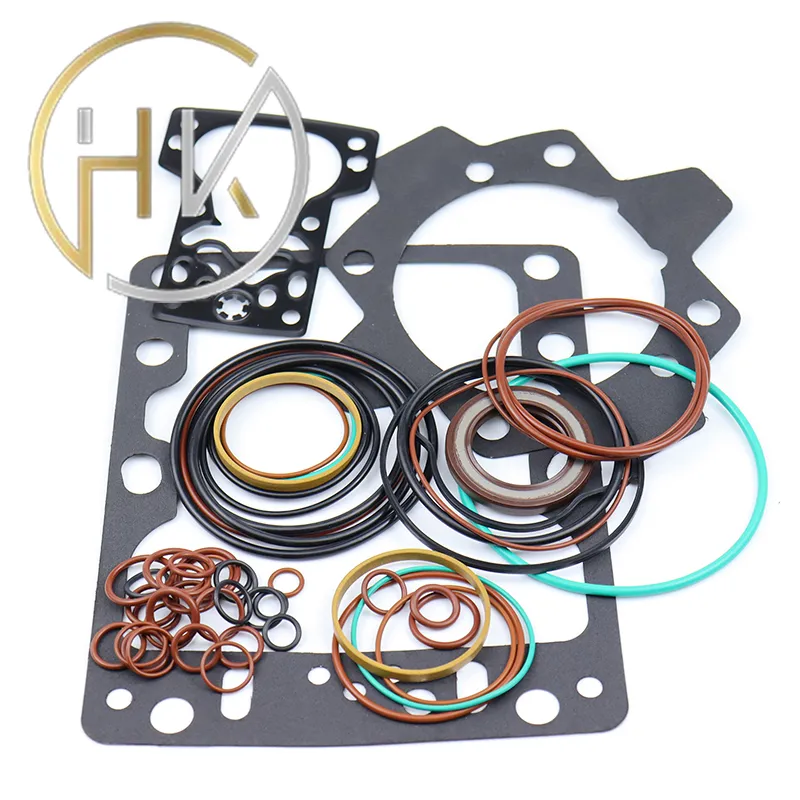

There are various types of seals used in hydraulic rams, each designed for specific applications and conditions

. Some of the most common types include1. O-Rings These circular rubber seals are one of the most popular sealing solutions, used for static and dynamic applications. They are easy to install and provide excellent sealing performance.

hydraulic ram seals

2. U-Cups Designed for dynamic applications where there is a need for sealing against pressure, U-cups are shaped like a 'U' and are effective in containing hydraulic fluid.

3. Rod Seals These seals are specifically designed for the piston rods in hydraulic ram systems. They prevent fluid leakage and maintain pressure within the cylinder.

4. Piston Seals These seals fit around the piston and serve to contain hydraulic fluid, ensuring that the ram functions effectively.

5. Backup Rings Often used in conjunction with other seals, backup rings prevent extrusion of the seals under high-pressure conditions.

Factors Affecting Seal Performance

The performance and lifespan of hydraulic ram seals are influenced by several factors, including

- Material Composition Seals can be made from various materials such as rubber, polyurethane, or PTFE (Teflon). The right material will depend on the operating temperature, pressure, and the type of hydraulic fluid used.

- Operating Conditions Factors such as temperature, pressure, and the presence of contaminants can significantly impact seal performance. High temperatures may cause seals to harden or degrade, while low temperatures can lead to brittleness.

- Installation Quality Proper installation of seals is essential. Incorrect installation can lead to early failure due to misalignment or improper fitting.

Maintenance and Replacement

Regular maintenance of hydraulic ram seals is essential for the longevity of hydraulic systems. Operators should routinely inspect seals for wear and tear, replacing them as necessary. Signs that seals may need replacement include visible leaks, decreased performance, and unusual noises during operation.

In conclusion, hydraulic ram seals play a crucial role in ensuring the efficiency and reliability of hydraulic systems. By understanding their functionality, types, and the factors influencing their performance, operators can take proactive measures to maintain their hydraulic machinery and avoid costly downtime. With the right seal solutions and proper maintenance practices, industries can enhance their operational efficiency and extend the lifespan of their equipment.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories