Nov . 18, 2024 20:37 Back to list

hydraulic ram seal replacement

Hydraulic Ram Seal Replacement A Step-by-Step Guide

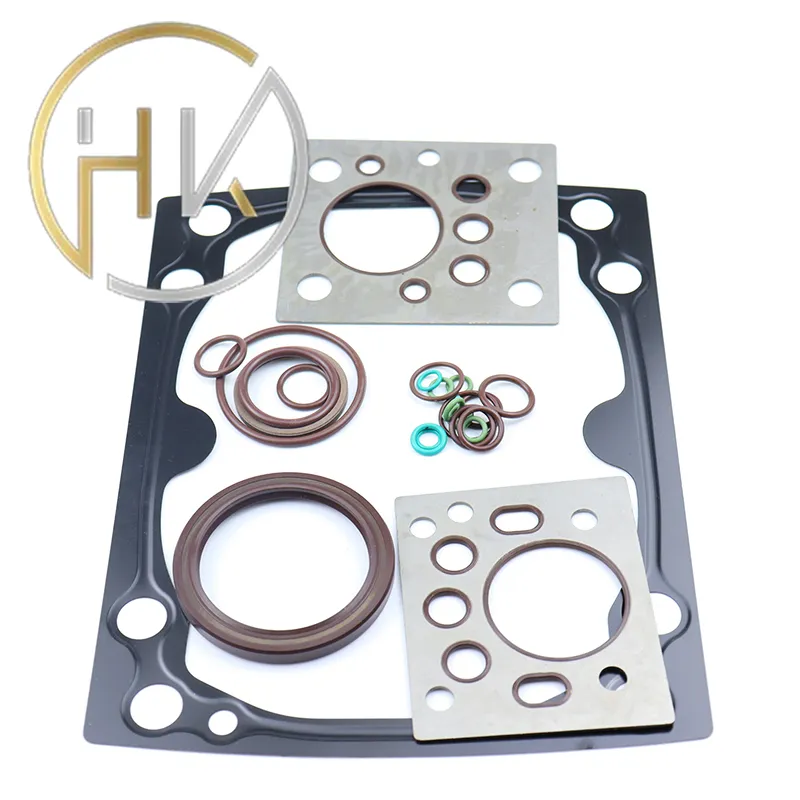

Hydraulic rams are essential components in many mechanical systems, from construction equipment to agricultural machinery. They operate using pressurized fluid to create motion, and like any mechanical element, they are subject to wear and tear. One common issue that arises with hydraulic rams is seal failure, leading to leaks and reduced performance. Replacing the seals is crucial to maintaining the efficiency and longevity of your hydraulic system. In this article, we will explore the process of hydraulic ram seal replacement, enabling you to perform this task with confidence.

Understanding Hydraulic Rams and Seals

Before diving into the replacement process, it's important to understand the role of the seals in a hydraulic ram. Seals are designed to prevent fluid leakage, maintain pressure within the hydraulic system, and protect internal components from contaminants. Common materials for seals include rubber, polyurethane, and various thermoplastics, each chosen for its durability and compatibility with hydraulic fluids.

Over time, seals can degrade due to abrasives, thermal fatigue, and chemical exposure. Signs of seal failure include fluid leaks, reduced pressure, and erratic operation of the hydraulic ram. Regularly inspecting seals for wear can help prevent costly damage and downtime.

Tools and Materials Needed

To replace seals in a hydraulic ram, you'll need the following tools and materials

- Safety goggles and gloves - Screwdriver set - Socket and wrench set - Seal removal tool or pick - New seals (ensure they are compatible with your specific hydraulic ram) - Hydraulic fluid - Gasket sealant (if needed) - Clean rags and a container for draining fluid

Step-by-Step Replacement Process

1. Safety First Before starting, ensure that the hydraulic system is fully depressurized. Disconnect the power supply and drain the hydraulic fluid into a safe container.

hydraulic ram seal replacement

2. Disassembly Using the appropriate tools, carefully remove the hydraulic ram from its mounting. Take note of how the components are arranged to facilitate reassembly later. Remove any external fittings, hoses, or connections.

3. Access the Seals Once the ram is disassembled, you will have access to the seals. Examine the assembly to determine the number and type of seals that need replacement.

4. Remove Old Seals Using a seal removal tool or a pick, carefully extract the old seals. Be cautious not to damage the mating surfaces of the ram, as this can lead to further issues down the line.

5. Clean the Surfaces With the old seals removed, clean the surfaces thoroughly using rags. Ensure that no debris or fragments remain, as these can cause new seals to fail prematurely.

6. Install New Seals Lubricate the new seals lightly with hydraulic fluid to ease installation. Position them correctly in their respective grooves. It’s essential to ensure that they fit snugly and evenly to prevent leaks.

7. Reassembly Once the new seals are in place, reassemble the hydraulic ram by reversing the disassembly steps. Be sure to tighten all fittings securely, according to the manufacturer’s specifications.

8. Fill with Hydraulic Fluid After reassembly, refill the hydraulic system with the appropriate hydraulic fluid. Check for any leaks during the filling process.

9. Testing Finally, reconnect the power supply and test the hydraulic ram. Monitor its operation closely to ensure that it is functioning properly and that no leaks are present.

Conclusion

Replacing the seals in a hydraulic ram may seem daunting, but with the right tools and a careful approach, it can be accomplished efficiently. Regular maintenance and timely seal replacement can significantly extend the life of your hydraulic equipment and enhance its performance. By following the steps outlined above, you can tackle seal replacement with confidence, ensuring that your hydraulic system continues to operate smoothly for years to come. Always remember to consult the manufacturer’s manual for specific recommendations and guidelines related to your hydraulic ram.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories