Nov . 18, 2024 00:52 Back to list

Hydraulic Ram Seal Replacement Guide for Optimal Performance and Maintenance

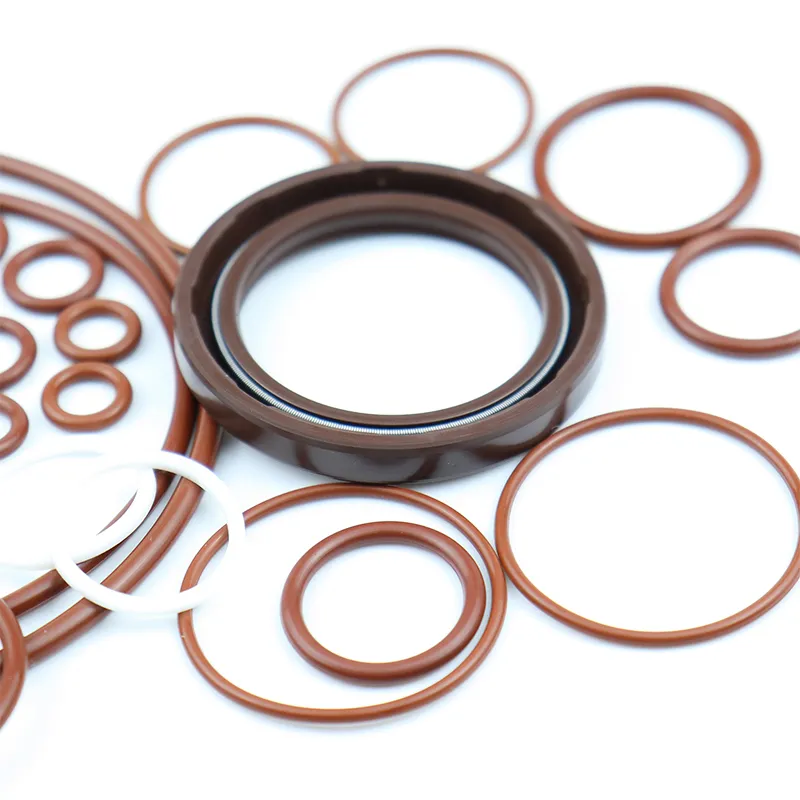

Understanding Hydraulic Ram Seal Replacement

Hydraulic ram seals are crucial components in any hydraulic system. They play a vital role in maintaining the efficiency and reliability of hydraulic machinery by preventing fluid leaks and ensuring proper pressure. Over time, these seals can wear out due to friction, temperature variations, and contamination, leading to reduced performance and potential damage to the hydraulic system. Therefore, replacing hydraulic ram seals is an important maintenance task that should not be overlooked.

The Importance of Seals in Hydraulic Rams

Seals in hydraulic rams keep the hydraulic fluid contained, allowing the system to generate and maintain the necessary pressure for operation. If a seal begins to fail, the hydraulic fluid can leak out, resulting in decreased efficiency and increased operating costs. Additionally, fluid leakage can lead to environmental hazards and safety concerns. Properly functioning seals ensure that the hydraulic system operates at its optimum level, thereby extending the life of the equipment.

Signs You Need to Replace Hydraulic Ram Seals

Identifying seal failure early can save you from more significant repair costs down the line. Some common signs that indicate it’s time to replace hydraulic ram seals include

hydraulic ram seal replacement

1. Visible Fluid Leaks If you notice fluid pooling around the hydraulic ram, it’s a clear indication that the seals may be compromised. 2. Loss of Pressure A drop in the system's hydraulic pressure can suggest that seals are worn and unable to maintain the required pressure. 3. Unusual Noise If you hear excessive noise during operation, it could indicate that the seals are deteriorating, resulting in internal movement that shouldn’t be occurring. 4. Decreased Performance Sluggish or erratic operation of the machinery is a sign that the seals may be allowing fluid to escape or become contaminated.

Replacement Process

Replacing hydraulic ram seals is a task that can be performed by trained personnel. The process typically involves the following steps

1. Disassemble the Hydraulic Ram Carefully disassemble the hydraulic ram to gain access to the seals. 2. Inspect Components While disassembled, inspect other components for wear or damage. 3. Remove Old Seals Carefully remove the old seals, ensuring not to scratch or damage the sealing surfaces. 4. Install New Seals Place the new seals, ensuring proper orientation and fit. 5. Reassemble and Test Reassemble the ram, refill the hydraulic fluid, and conduct a pressure test to ensure there are no leaks.

Conclusion

Regular inspection and timely replacement of hydraulic ram seals are essential for the reliable operation of hydraulic systems. By recognizing the signs of seal failure early and understanding the replacement process, you can ensure your hydraulic machinery remains in optimal condition, enhancing both performance and safety. Prioritize seal maintenance to prolong the life of your hydraulic systems and prevent costly downtime.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories