Dec . 13, 2024 22:25 Back to list

Hydraulic Ram Seal Kit Replacement Parts for Enhanced Performance and Durability

Understanding Hydraulic Ram Seal Kits Essential Components for Optimal Performance

Hydraulic ram systems play a crucial role in various industrial applications, ranging from construction to agriculture. A hydraulic ram is a device that uses the principles of hydraulics to lift heavy loads efficiently. However, the efficiency and reliability of a hydraulic ram depend significantly on the health of its components, particularly the seal kits. In this article, we will delve into the importance of hydraulic ram seal kits, their components, and how to maintain them for optimal performance.

What is a Hydraulic Ram Seal Kit?

A hydraulic ram seal kit is a collection of sealing components designed to prevent fluid leaks and maintain pressure within hydraulic systems. These kits usually consist of a variety of gaskets, O-rings, seals, and backup rings, all specifically engineered to fit various models of hydraulic rams. Their primary function is to ensure that hydraulic fluid remains contained within the system, thus allowing for efficient force amplification and movement.

Importance of Seal Kits in Hydraulic Rams

1. Leak Prevention One of the foremost roles of seal kits is to prevent hydraulic fluid leaks. Over time, even minor leaks can lead to significant losses in pressure, reducing the efficiency of the hydraulic system and increasing operational costs.

2. Pressure Maintenance The seals in the kit help maintain the necessary pressure levels within the hydraulic ram. This is vital for the proper operation of the system, as variations in pressure can lead to inconsistent performance and potential system failure.

3. Contamination Protection Seal kits also serve as a barrier against contaminants such as dirt, dust, and moisture. Keeping these harmful elements out of the hydraulic system helps prolong the lifespan of both the seals and the hydraulic ram itself.

4. Operational Safety A well-maintained hydraulic system is safer to operate. Leaks can lead to hazardous working conditions, posing risks to operators and equipment. Effective seal kits minimize this risk by ensuring that the hydraulic system functions safely and reliably.

Components of Hydraulic Ram Seal Kits

Hydraulic ram seal kits typically include various components that work together to provide an effective sealing solution

. Some of the key components include- O-Rings Used to create a seal between two surfaces, preventing leaks in hydraulic systems. They are made from various materials, such as nitrile, fluorocarbon, or silicone, each suited for specific fluid types and temperatures.

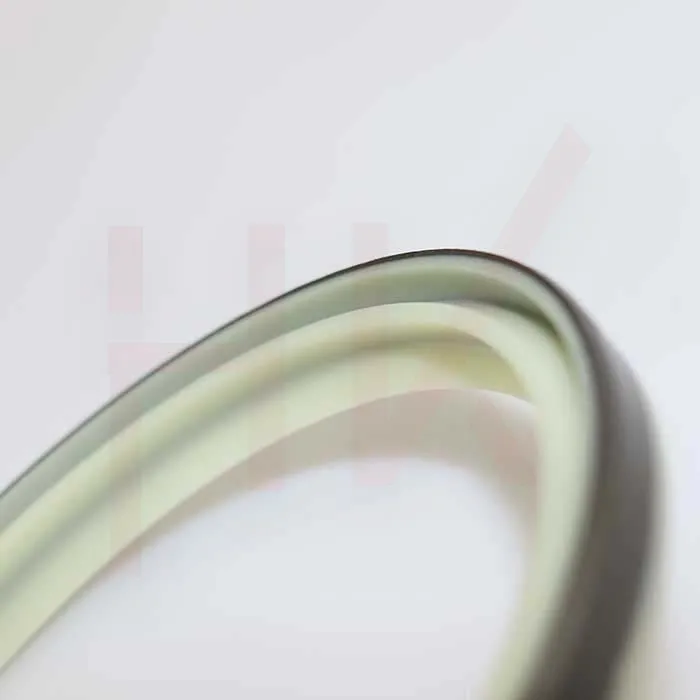

hydraulic ram seal kit

- Gaskets These flat pieces help create seals between rigid components, ensuring a tight fit and preventing leaks. Gaskets can be made from rubber, cork, or composite materials, depending on the application.

- Seals Various types of seals, including lip seals and wiper seals, are utilized to prevent the ingress of contaminants and the egress of hydraulic fluid. Their design is crucial for their effectiveness.

- Backup Rings Used in conjunction with O-rings, backup rings provide additional support and help prevent extrusion under high pressure, extending the life of the seals.

Maintenance Tips for Hydraulic Ram Seal Kits

To ensure the longevity and performance of hydraulic ram seal kits, regular maintenance is essential. Here are some tips to keep in mind

1. Regular Inspection Periodically inspect seals and gaskets for visible wear, cracks, or deformation. Early detection of issues can prevent larger problems down the line.

2. Fluid Quality Use high-quality hydraulic fluid recommended for your system to prevent chemical degradation of seals.

3. Clean Environment Keep the hydraulic system clean and free from contaminants. Dirt and debris can compromise seal integrity and lead to failures.

4. Proper Installation Ensure that seals and gaskets are installed correctly to avoid damage during assembly. Follow manufacturer specifications for torque and alignment.

5. Replace as Needed Don't wait for a leak to occur. Replace seals and gaskets at regular intervals as part of a preventative maintenance program.

In conclusion, hydraulic ram seal kits are vital for the optimal performance and safety of hydraulic systems. Understanding their components and maintaining them properly can lead to significant improvements in efficiency, cost savings, and reliability. Investing in high-quality seal kits and adhering to maintenance schedules will ensure that your hydraulic rams operate smoothly for years to come.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories