Dec . 01, 2024 06:15 Back to list

Hydraulic Ram Seal Kit Replacement for Enhanced Performance and Durability

The Importance of Hydraulic Ram Seal Kits in Machinery Maintenance

In the world of hydraulics, efficiency and reliability are paramount. One critical component in maintaining the performance of hydraulic systems is the hydraulic ram seal kit. These kits not only enhance operational efficiency but also extend the lifespan of hydraulic rams, which play a vital role in numerous applications, from industrial machinery to construction equipment. This article delves into the significance of hydraulic ram seal kits, their components, and the best practices for maintenance.

Understanding Hydraulic Rams

Hydraulic rams are devices that use hydraulic fluid to create a lifting force. They work on the principle of converting hydraulic energy into mechanical energy, which can then be applied for lifting, pushing, or holding. Because they operate under high pressure and continuous motion, hydraulic rams are prone to wear and tear, particularly in seals and gaskets. This is where hydraulic ram seal kits come into play.

Components of a Hydraulic Ram Seal Kit

A typical hydraulic ram seal kit includes various components essential for ensuring a proper seal and maintaining the performance of the hydraulic ram. Key components often found in these kits include

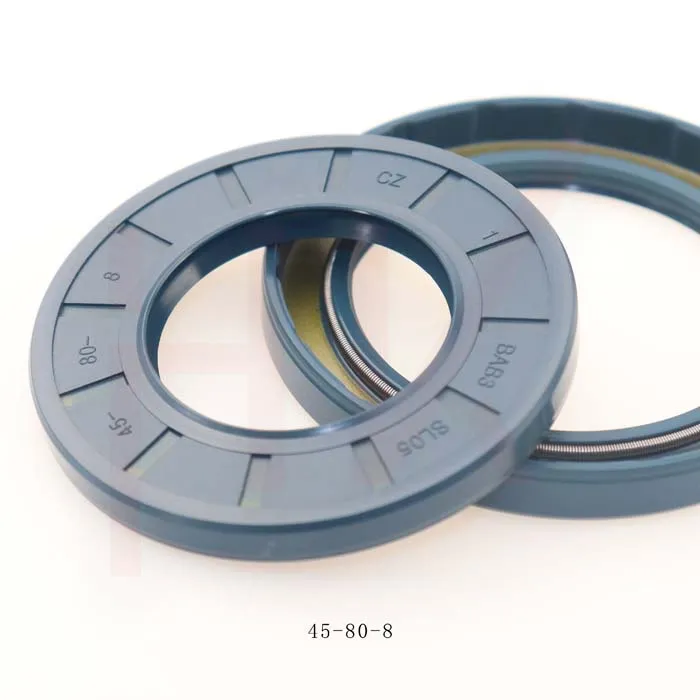

1. Seals These are the primary components that prevent fluid leakage. They come in various shapes and sizes, designed to fit specific hydraulic ram models. Common seal types include O-rings, U-cups, and backup rings.

2. Gaskets Gaskets provide sealing surfaces between two or more component parts, preventing leakage at joints.

3. Dust Wipers Dust wipers are essential for keeping contaminants away from the seals, preventing premature wear.

4. Retaining Rings These are used to hold seals and other components in place, ensuring that the hydraulic ram functions correctly.

5. Lubricants Some kits may include specialized lubricants that enhance the performance of the seals and extend their lifespan.

The Role of Seal Kits in Maintenance

Maintaining hydraulic rams involves regular inspection and replacement of worn components. The hydraulic ram seal kit serves as a proactive solution to potential failures. Here are a few reasons why these kits are important for maintenance

hydraulic ram seal kit

1. Preventing Downtime Regular replacement of seals using a seal kit can significantly reduce the likelihood of hydraulic failures that lead to machine downtime. This is crucial for industries where time is money.

2. Cost-Effectiveness Investing in a hydraulic ram seal kit may seem like an additional expense; however, it is cost-effective in the long run. By preventing leaks and optimizing performance, these kits reduce the need for extensive repairs or complete replacements of hydraulic rams.

3. Enhancing Safety Leaking hydraulic fluid poses safety hazards, including environmental risks and the potential for equipment failure. By maintaining a tight seal, these kits promote safer operating conditions.

4. Improving Performance Regularly serviced hydraulic rams operate more efficiently. Using a seal kit ensures that the hydraulic ram maintains optimal pressure and performance, which enhances overall productivity.

Best Practices for Using Hydraulic Ram Seal Kits

To maximize the benefits of hydraulic ram seal kits, consider the following best practices

1. Regular Inspections Schedule routine inspections of hydraulic rams to identify signs of wear or leakage early.

2. Use OEM Seal Kits When replacing seals, always opt for Original Equipment Manufacturer (OEM) seal kits that are specifically designed for your hydraulic ram model. This ensures compatibility and better performance.

3. Follow Installation Guidelines Proper installation is crucial for the effectiveness of seal kits. Follow manufacturer instructions carefully to avoid improper sealing or damaging seals during installation.

4. Maintain Cleanliness Keep the work area and components clean during installation to prevent contamination, which could lead to premature seal failure.

5. Monitor Performance After installation, monitor the hydraulic ram's performance closely to ensure that the seals are functioning correctly and that there are no leaks.

Conclusion

Hydraulic ram seal kits are essential for the longevity and efficiency of hydraulic systems. Regular maintenance and timely replacement of seals can prevent costly repairs and ensure safe operation. Investing in quality seal kits not only enhances performance but also contributes to the overall productivity of machinery. As such, operational success in industries reliant on hydraulic systems often hinges on the seemingly small but critical component the hydraulic ram seal kit.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories