Nov . 18, 2024 09:53 Back to list

hydraulic ram seal kit

Understanding Hydraulic Ram Seal Kits Essential Components for Optimal Performance

Hydraulic systems are pivotal in various industries, ranging from construction and manufacturing to automotive and aerospace. Among the numerous components that contribute to the efficiency and reliability of hydraulic systems, the hydraulic ram seal kit stands out as a crucial element. This article delves into the role of hydraulic ram seal kits, their components, selection criteria, maintenance practices, and their significant impact on system performance.

What Is a Hydraulic Ram Seal Kit?

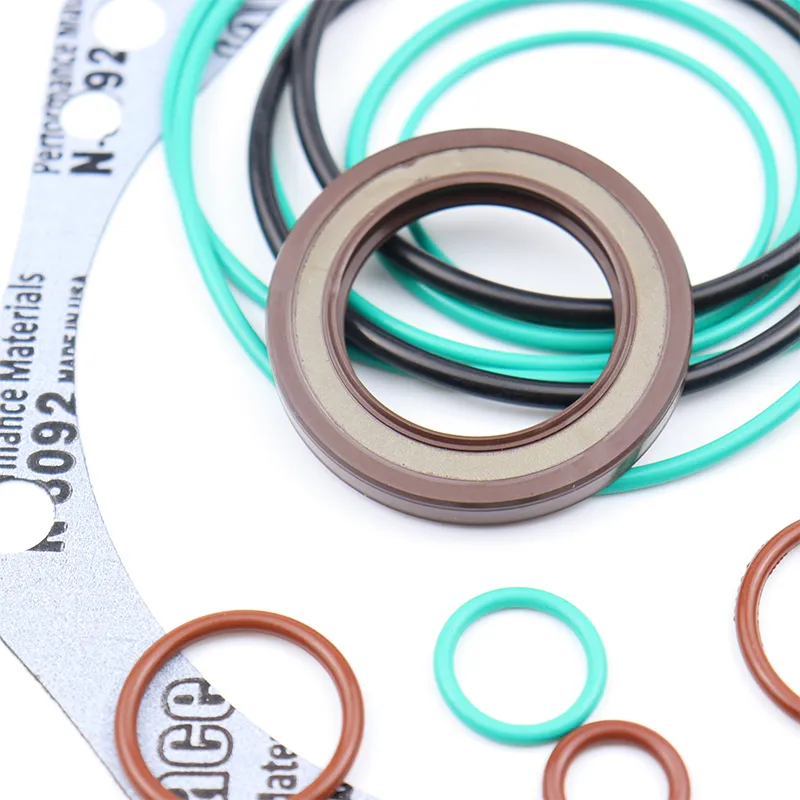

A hydraulic ram is a powerful device that utilizes hydraulic pressure to perform work, such as lifting heavy loads or operating machinery. The hydraulic ram seal kit is a collection of seals and related components designed to prevent hydraulic fluid leaks, maintain pressure, and protect the internal components from contaminants. These kits generally include various types of seals, such as O-rings, backup rings, and wipers, each serving a specific function within the hydraulic system.

Components of a Hydraulic Ram Seal Kit

1. O-Rings These circular seals are made from elastomeric materials and are designed to fit into grooves in the hydraulic ram. They create a watertight seal that prevents fluid from escaping and contaminants from entering.

2. Backup Rings These rings are used in conjunction with O-rings to prevent extrusion and enhance the sealing capability, especially in high-pressure applications.

3. Wipers Wiper seals are installed at the exterior of the ram and function to keep out dirt and debris while ensuring that the hydraulic fluid does not leak out. They are essential for maintaining the longevity of the hydraulic components.

4. Rod Seals These seals are placed at the base of the ram to prevent fluid loss while allowing the ram to move smoothly.

5. Bushing and Bearings While not strictly part of the seal kit, they support the ram’s movement and reduce wear and tear on the seals.

Importance of Selecting the Right Seal Kit

Selecting the appropriate hydraulic ram seal kit involves considering several factors

- Material Compatibility Different fluids and operational temperatures require seals made from specific materials. Common materials include Nitrile, Viton, and Polyurethane. Each has its unique properties regarding temperature tolerance and chemical resistance.

hydraulic ram seal kit

- Pressure Ratings Hydraulic systems operate under varying pressure levels. The seal kit must be rated for the maximum pressure to ensure sealing integrity and performance.

- Size and Geometry The dimensions of the seal must match the specifications of the hydraulic ram. A mismatch can lead to performance issues, including leaks and premature wear.

- Operational Environment Considerations such as temperature extremes, exposure to chemicals, and the presence of particulate matter can influence seal material selection.

Maintenance and Care

Regular maintenance is essential for extending the life of hydraulic ram seal kits and ensuring optimal system performance. Here are some recommended practices

1. Routine Inspections Regularly check seals for signs of wear or damage, such as cracks, swelling, or deformation. Prompt replacement of damaged seals is crucial.

2. Fluid Quality Always use the recommended hydraulic fluids and regularly check for contamination. Contaminated fluids can wear down seals rapidly.

3. Environmental Control Maintain the work environment by minimizing dirt, dust, and other contaminants that can infiltrate the hydraulic system. Use wiper seals to reduce this risk.

4. Correct Installation Ensure that seals are correctly installed according to manufacturer specifications. Incorrect installation can lead to leaks and system failure.

5. Monitor Performance Keep an eye on the performance of the hydraulic ram. Slow operation, unexpected leaks, or the need for frequent re-filling of hydraulic fluid may indicate seal failure.

Conclusion

Hydraulic ram seal kits are indispensable components that ensure the efficient operation of hydraulic systems. By preventing leaks, maintaining pressure, and blocking contaminants, these kits play a vital role in enhancing the performance and longevity of hydraulic machinery. Understanding the composition, selection criteria, and maintenance of hydraulic ram seal kits can aid in maximizing operational efficiency and minimizing downtime in various applications. Therefore, careful attention to these aspects is essential for anyone involved in the maintenance of hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories