Oct . 13, 2024 07:18 Back to list

hydraulic pump seal kit

Understanding Hydraulic Pump Seal Kits Importance and Functionality

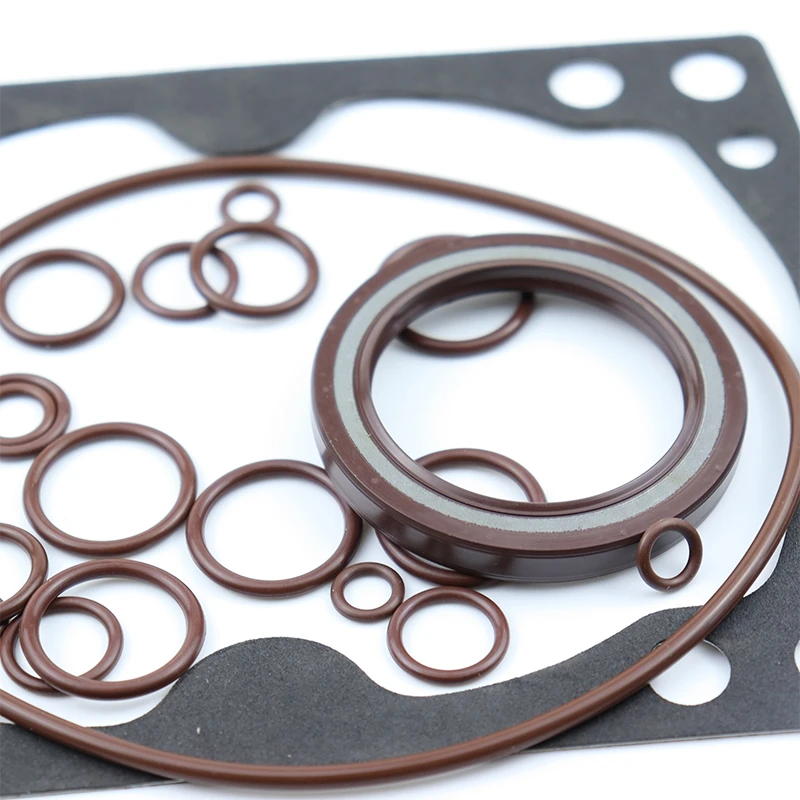

Hydraulic pump seal kits play a crucial role in the maintenance and efficiency of hydraulic systems. These kits contain a variety of seals, O-rings, and related components that ensure the proper functioning of hydraulic pumps. In hydraulic systems, pumps are responsible for transferring fluid under pressure to move machinery parts. Any leakage or malfunction can lead to inefficiency, increased operational costs, and potential damage to the machinery.

The Anatomy of a Hydraulic Pump Seal Kit

A typical hydraulic pump seal kit includes several essential components. The most common items are

1. O-Rings These circular seals are vital for preventing fluid leaks. They are made from materials such as rubber, silicone, or polyurethane which offer durability and flexibility to withstand high pressures and temperatures.

2. Gaskets Gaskets fill the space between two or more mating surfaces, creating a seal that prevents fluid from leaking. They are available in various shapes and sizes to fit different types of hydraulic pumps.

3. Backup Rings Often used in conjunction with O-rings, backup rings are designed to prevent extrusion of the O-ring under high-pressure conditions, thus prolonging their lifespan.

4. V-Seals These seals provide additional protection, acting as a barrier against dirt and contaminants while maintaining pressure integrity.

hydraulic pump seal kit

5. Dust Seals Essential for keeping out debris and moisture, dust seals enhance the longevity of hydraulic systems by preventing contamination that could otherwise lead to failure.

Importance of Seal Kits in Hydraulic Systems

The integrity of seals within hydraulic pumps is paramount for maintaining operational efficiency. When seals are compromised, hydraulic fluid can leak, leading to a loss of pressure and performance. This not only affects productivity but can also cause significant damage to other components within the system. Regular maintenance using hydraulic pump seal kits helps in avoiding unexpected breakdowns, reducing downtime, and enhancing the overall lifespan of machinery.

Additionally, using high-quality seal kits is essential. Authentic or OEM (Original Equipment Manufacturer) seal kits are specifically designed for particular models of hydraulic pumps and ensure optimal fit and performance. In contrast, generic or substandard seal kits may save money initially but can lead to frequent replacements, system inefficiencies, and even catastrophic failures.

Choosing the Right Seal Kit

When selecting a hydraulic pump seal kit, factors such as the type of hydraulic fluid, operating pressure, and temperature range should be considered. It's also important to ensure compatibility with the specific pump model. Consulting the manufacturer’s guidelines or a professional can aid in making the correct choice.

Conclusion

In conclusion, hydraulic pump seal kits are a vital part of any hydraulic system. They not only prevent leaks but also contribute to the overall efficiency and longevity of machinery. By understanding the components and importance of these kits, operators can ensure better maintenance practices that lead to optimal performance in their hydraulic systems. Investing in quality seal kits and performing regular checks can save time, resources, and enhance productivity in the long run.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories