Dec . 13, 2024 13:54 Back to list

Hydraulic Piston Seal Kit for Enhanced Performance and Durability in Fluid Systems

Understanding Hydraulic Piston Seal Kits Essential Components for Efficient Performance

Hydraulic systems play a crucial role in various industrial and machinery applications, including construction equipment, manufacturing processes, and automotive systems. At the heart of these systems lies the hydraulic piston, a critical component responsible for converting hydraulic pressure into mechanical force. However, to ensure the efficient and safe operation of hydraulic pistons, the right sealing solutions are necessary. This is where hydraulic piston seal kits come into play.

What is a Hydraulic Piston Seal Kit?

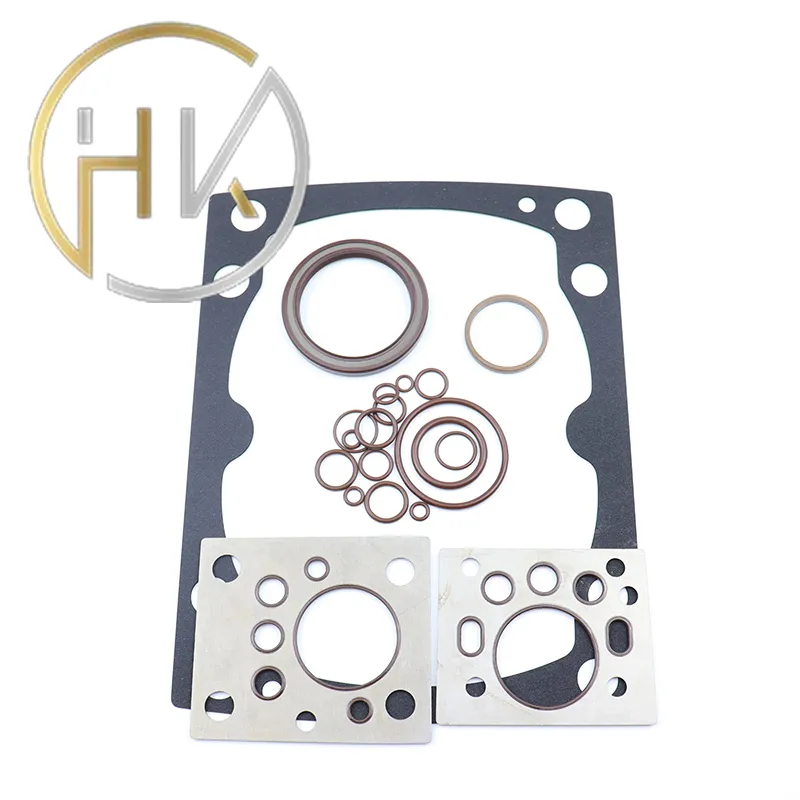

A hydraulic piston seal kit consists of various sealing components designed to prevent fluid leakage and contamination in hydraulic systems. These kits generally include different types of seals such as O-rings, piston seals, backup rings, and guide rings. Each component serves a specific purpose, contributing to the overall functionality of the hydraulic piston and the system as a whole.

Importance of Seals in Hydraulic Systems

The primary function of seals in hydraulic systems is to maintain pressure integrity while preventing fluid leakage. A well-sealed hydraulic piston can effectively convert hydraulic fluid pressure into linear motion without experiencing unwanted loss of fluid or energy. Leakage can lead to reduced efficiency, increased operational costs, and can even compromise the safety of the entire system. Therefore, using high-quality seals is critical for prolonging the lifespan of hydraulic components and ensuring reliable operation.

Types of Seals in Hydraulic Piston Seal Kits

1. O-Rings O-rings are circular sealing elements that are placed in grooves to create a tight seal. They are made from various materials like Nitrile, Viton, or polyurethane, depending on the operating environment and fluid compatibility. O-rings are often used in conjunction with other seals to enhance sealing performance.

2. Piston Seals Piston seals, often referred to as rod seals, are designed to prevent hydraulic fluid from leaking out of the piston while also preventing contaminants from entering the system. These seals are typically made from rubber or other elastomer materials that can withstand high pressures and varying temperatures.

hydraulic piston seal kit

3. Backup Rings Backup rings are non-elastic rings that are used in conjunction with O-rings and piston seals to provide additional support and prevent extrusion under high pressure. They help in maintaining the compressive force on the sealing elements, thereby enhancing their longevity.

4. Guide Rings Guide rings are used to guide the piston within the cylinder, reducing friction and wear. They ensure smooth operation by keeping the piston aligned and preventing it from wobbling during movement. Guide rings are usually made from materials like PTFE or other low-friction polymers.

Choosing the Right Hydraulic Piston Seal Kit

Selecting the appropriate hydraulic piston seal kit involves considering several factors, including the type of hydraulic fluid, the operating temperature range, pressure conditions, and the specific application. It is essential to match the seal materials to the hydraulic fluids to prevent chemical degradation and ensure optimal performance.

Moreover, it is crucial to consider the manufacturer’s specifications and to utilize kits that are designed for specific hydraulic systems. Using generic or inferior seal kits may lead to premature failure and costly repairs.

Maintenance and Replacement

Regular inspection and maintenance of hydraulic seals are vital for timely detection of wear and tear. Signs of failing seals can include fluid leakage, decreased performance, and unusual noises. Replacing defective seals promptly ensures the continued efficiency and safety of hydraulic systems.

In conclusion, hydraulic piston seal kits are indispensable for the optimal functioning of hydraulic systems. Understanding the components within these kits and their significance can help in making informed decisions about maintenance, repairs, and replacements. By investing in high-quality seal kits and ensuring proper application, users can enhance the efficiency and longevity of hydraulic machinery, ultimately leading to reduced operational costs and improved productivity.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories