Nov . 17, 2024 04:12 Back to list

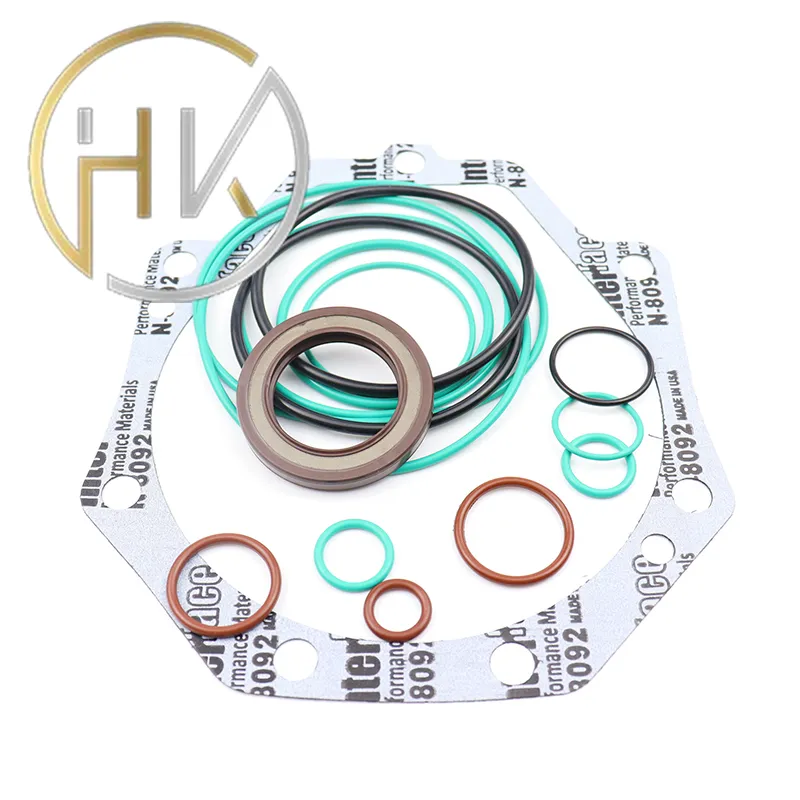

hydraulic piston seal kit

Understanding Hydraulic Piston Seal Kits Essential Components for Reliable Performance

Hydraulic systems are integral in a variety of industries, from manufacturing and construction to aviation and automotive. At the heart of these systems lies the hydraulic piston, a vital component responsible for converting hydraulic energy into mechanical force. However, the efficiency and longevity of a hydraulic piston are heavily reliant on one often-overlooked element the hydraulic piston seal kit.

What is a Hydraulic Piston Seal Kit?

A hydraulic piston seal kit is a collection of seals and gaskets designed to prevent fluid leakage and maintain pressure within hydraulic systems. These kits typically include several different types of seals, each serving a specific purpose. The primary components of a hydraulic piston seal kit usually include

1. Piston Seals These seals prevent hydraulic fluid from leaking around the piston. They are usually made from materials such as polyurethane or rubber and can withstand high pressures and temperatures.

2. Rod Seals Rod seals function similarly to piston seals but are located on the piston rod. They are essential for preventing fluid from escaping the cylinder as the rod moves in and out.

3. Wipers These seals are located at the entrance of the cylinder and work to keep contaminants such as dirt and dust out of the hydraulic system by wiping the rod as it exits.

4. Backup Rings These rings are used in conjunction with the primary seals to provide additional support and prevent extrusion of the seals under high pressures.

Importance of Seal Kits

The effectiveness of hydraulic systems is highly dependent on the integrity of the seals. Any failure or degradation of these seals can result in fluid loss, leading to reduced efficiency, increased operational costs, and potentially catastrophic failure of the hydraulic system. Therefore, regular maintenance and timely replacement of seal kits are crucial.

hydraulic piston seal kit

2. Enhancing Performance Proper seals help maintain pressure, ensuring that hydraulic systems function correctly. This leads to more efficient operation and maximized productivity.

3. Extending Lifespan By preventing contaminants from entering the hydraulic system, seals protect vulnerable components from wear and tear, extending the overall lifespan of the equipment.

4. Safety Leaks in hydraulic systems can pose safety risks to workers and the surrounding environment. Maintaining the integrity of hydraulic seals is a necessary measure for workplace safety.

Selection of Seal Kits

When selecting a hydraulic piston seal kit, several factors must be considered to ensure optimal performance

1. Material Compatibility The choice of material is critical. The seals must be compatible with the specific hydraulic fluid used in the system as well as be able to withstand the operational pressures and temperatures.

2. Sizing Accurate sizing of seals is essential. Overly tight or loose seals can cause failures. It’s crucial to consult specifications or measure existing seals when selecting replacements.

3. Application Requirements Different applications may have unique requirements. Understanding the specific needs of your hydraulic system will help in choosing appropriate seals.

4. Quality Not all seal kits are created equal. Investing in high-quality seals from reputable manufacturers can provide better performance and longer service life, reducing the frequency of maintenance and replacements.

Conclusion

In conclusion, hydraulic piston seal kits are critical to the reliability and efficiency of hydraulic systems. Regular maintenance, timely replacement, and the right seal selection can significantly enhance the performance of hydraulic equipment. As industries continue to rely on hydraulic systems for numerous applications, understanding and prioritizing the importance of hydraulic piston seal kits will be essential for maintaining operational efficiency and safety in the workplace. Whether in manufacturing, construction, or other fields, investing in quality hydraulic seal kits is a step toward ensuring the longevity and reliability of hydraulic systems.

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

-

Rotary Lip Seal Spring-Loaded Design for High-Speed Applications

NewsJul.25,2025

-

Hydraulic Cylinder Seals Polyurethane Material for High-Impact Jobs

NewsJul.25,2025

-

High Pressure Oil Seal Polyurethane Coating Wear Resistance

NewsJul.25,2025

-

Dust Proof Seal Double Lip Design for Construction Equipment

NewsJul.25,2025

-

Hub Seal Polyurethane Wear Resistance in Agricultural Vehicles

NewsJul.25,2025

-

The Trans-formative Journey of Wheel Hub Oil Seals

NewsJun.06,2025

Products categories