Feb . 02, 2025 02:39 Back to list

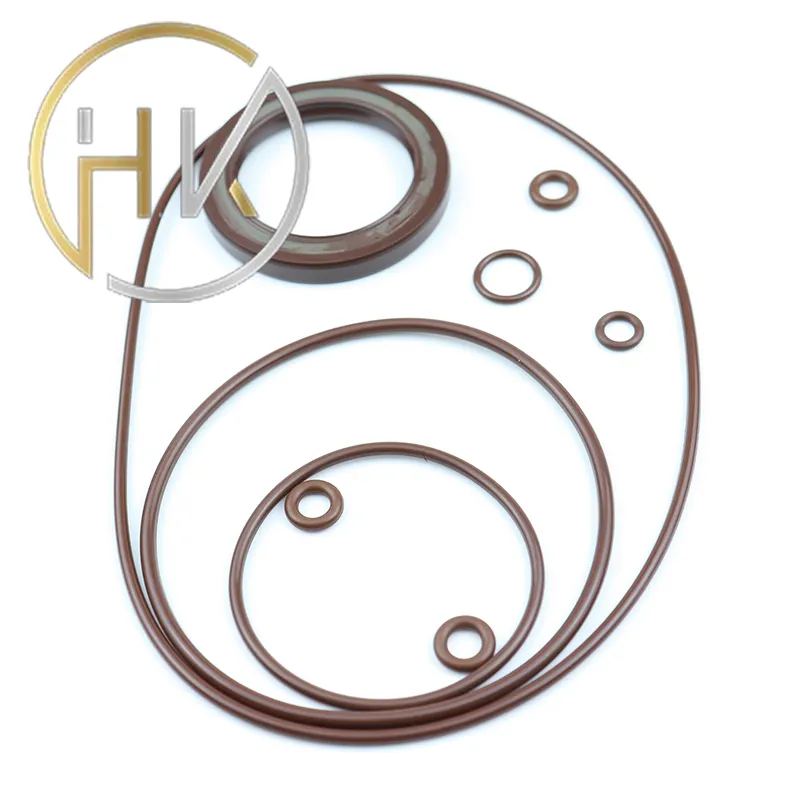

oil seal tcv

Authoritativeness is demonstrated through industry certifications and partnerships. Leading hydraulic oil seal suppliers are typically certified by international standards organizations, reflecting their commitment to quality and reliability. Additionally, partnerships with renowned machinery manufacturers lend further credibility, showing that they are trusted within the industry to provide essential components that meet rigorous requirements. Trustworthiness is perhaps the most crucial aspect when selecting a supplier, as it encompasses reliability, reputation, and customer service. A trustworthy supplier will not only deliver high-quality seals but will also stand by their products with warranties and support. Providing thorough documentation and transparency throughout the production process fosters trust that is particularly important when functioning in mission-critical environments where failure is not an option. In conclusion, the essential role of hydraulic oil seals in maintaining system integrity necessitates careful consideration when choosing a supplier. Those who exemplify experience, expertise, authoritativeness, and trustworthiness offer significant advantages, ensuring that hydraulic systems operate smoothly and efficiently. By prioritizing these qualities, businesses can secure a partnership with a supplier that understands their needs and upholds the highest standards of performance and reliability.

-

Unlocking the Potential of Hydraulic Systems with Essential Sealing Solutions

NewsAug.06,2025

-

Unleash the Power of Your Hydraulic Systems with Our Premium Seal Kits

NewsAug.06,2025

-

Specialized Hydraulic Seal Kits for Breakers, Pistons, and Presses

NewsAug.06,2025

-

Revitalize Hydraulic Systems with Premium Repair and Seal Kits

NewsAug.06,2025

-

Fortify Your Cylinders with Premium Sealing Solutions

NewsAug.06,2025

-

Elevate Hydraulic System Reliability with Specialized Seal Kits

NewsAug.06,2025

-

TCN Oil Seal Metal Ring Reinforcement for Heavy Machinery

NewsJul.25,2025

Products categories